Load Cell Weight Sensor

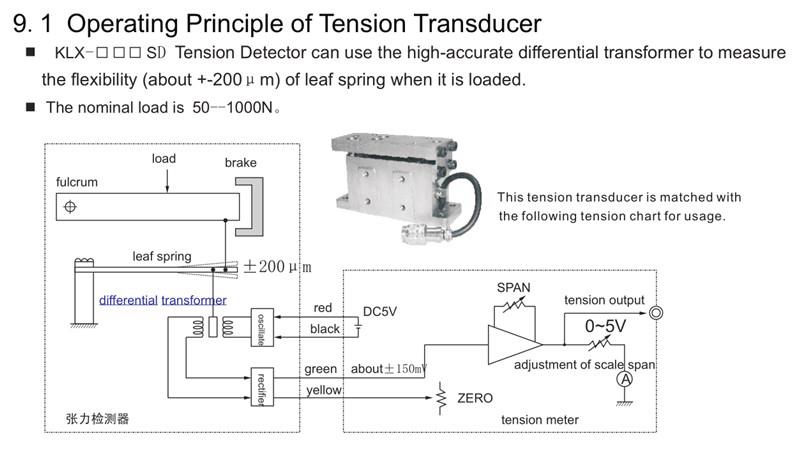

The strain gauge inside the tension sensor is a resistance strain gauge. The working principle is: The working principle of the metal resistance strain gauge is a phenomenon in which the strain resistance adsorbed on the base material changes with the mechanical deformation, which is commonly...

The strain gauge inside the tension sensor is a resistance strain gauge. The working principle is:

The working principle of the metal resistance strain gauge is a phenomenon in which the strain resistance adsorbed on the base material changes with the mechanical deformation, which is commonly called the resistance strain effect. The resistance value of the metal conductor can be expressed by the following formula:

Where: ρ——resistivity of metal conductor (Ω?cm2/m)

S——cross-sectional area of the conductor (cm2)

L——the length of the conductor (m)

Take wire strain resistance as an example. When the wire is subjected to external force, its length and cross-sectional area will change. It can be easily seen from the above formula that the resistance value will change if the wire is subjected to external force. When it is stretched, its length increases, and the cross-sectional area decreases, and the resistance value increases. When the wire is compressed by an external force, the length is decreased and the section is increased, and the resistance value is decreased. As long as the change in resistance is measured (usually the voltage across the measured resistance), the strain of the strained wire can be obtained.

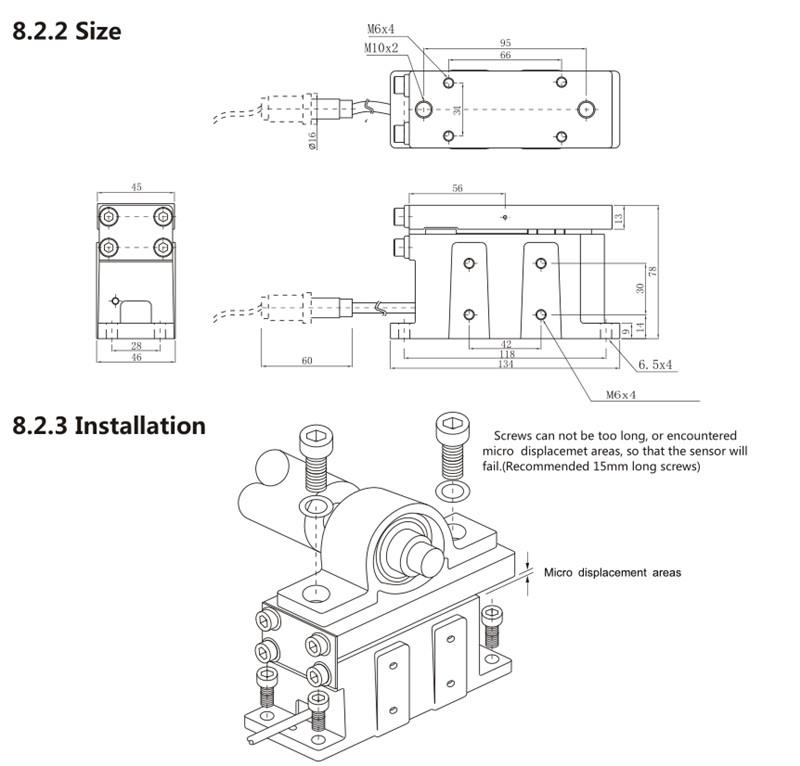

Foot Mounted Tension Sensor

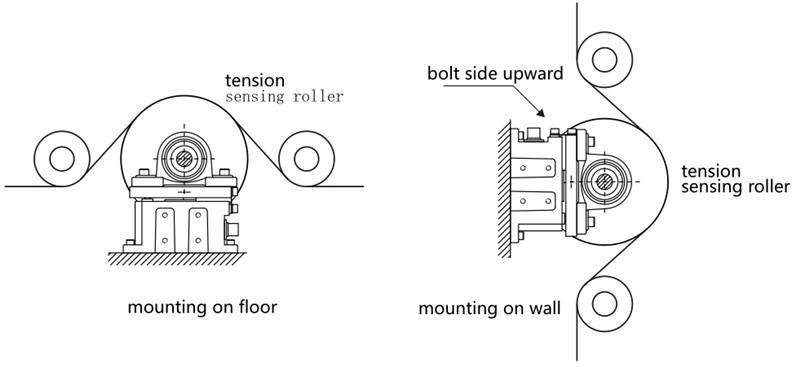

Mounting of Tension Sensors:

Take note of those topics while putting in the tension sensor

1. while installing the tension sensor, pay attention to the tension sensor. the screw ought to not be too lengthy. the bearing seat is likewise the identical. the screw cannot be selected too long. in any other case, the spring piece of the tension sensor can not work commonly, so the tension can't be detected. overall performance.

2. while installing the tension sensor, you want to apply the facet to repair it. you can not use the long screw when fixing. if you use the long screw, the measuring tool in the tension sensor might be broken without problems.

3. whilst putting in the tension sensor, it is vital to take note of the behavior that the tension sensor can not be subjected to excessive effect, in any other case the tension sensor can be effortlessly damaged.

Four. after the tension sensor is mounted, it's far vital to pay attention to check it as soon as, as a way to keep away from missing elements, or during the set up system, there's no observe that a few places are damaged. best after particular inspection can the tension sensor be efficaciously included. operation.

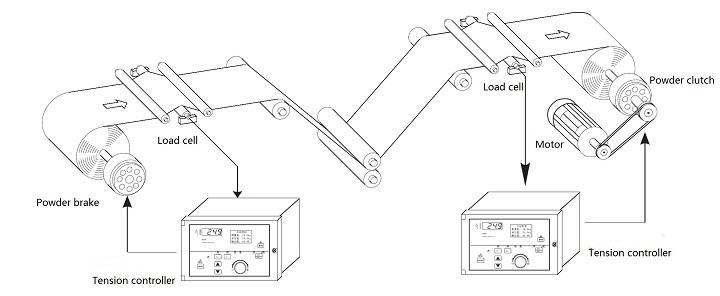

Application

Order Details

Item Name | LX Foot-Mounted Tension Detector |

MOQ(Minimum Order Quantity) | 1Pair(2pcs) |

Lead time | 2 days after receiving the deposit |

Calculated Packing Size | 20cm*15cm*15cm,4kg/Pair/2pcs |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: load cell weight sensor, China, manufacturers, suppliers, factory, quotation, pricelist, buy