Magnetic Slip Clutch

Magnetic powder clutch features 1. The excitation current—the transmission/braking torque has a good linear relationship, which reflects the good torque controllability of the magnetic powder clutch. By adjusting the excitation current, the transmission/braking torque can be easily controlled....

Magnetic powder clutch features

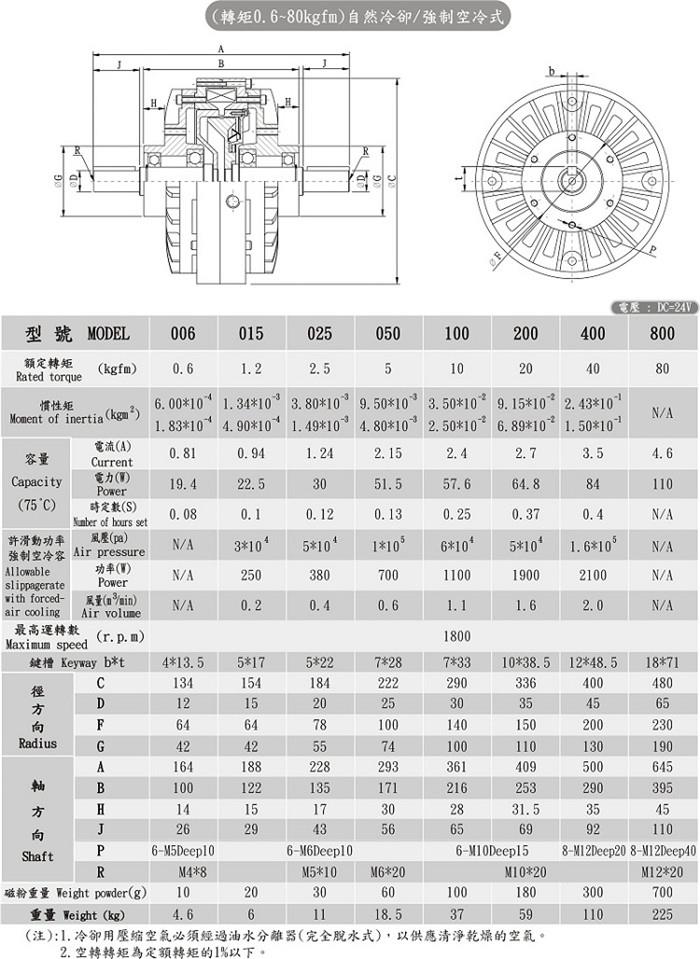

1. The excitation current—the transmission/braking torque has a good linear relationship, which reflects the good torque controllability of the magnetic powder clutch. By adjusting the excitation current, the transmission/braking torque can be easily controlled. Simplified torque control provides great convenience.

2. The transmission/braking torque is only controlled by the excitation current, and has nothing to do with the speed, relative speed and other factors, which embodies the accuracy of the magnetic powder clutch torque control and greatly improves the control accuracy.

3. The magnetic powder clutch has a reasonable heat dissipation structure and a large heat capacity, allowing long-term operation under continuous slip conditions.

4. The non-response time of the magnetic powder clutch is short, the torque time constant is small, the response speed is fast, and the combination and separation are stable without impact, vibration and noise.

5. The magnetic powder clutch has compact structure, high strength, reasonable design of magnetic circuit, small magnetic leakage, no leakage, reliable operation, high performance and high price ratio. High-quality alloy magnetic powder is used, which is resistant to wear, aging and long service life.

6. The magnetic powder clutch has small idling torque, good opening and closing performance, convenient operation and control, accurate and reliable.

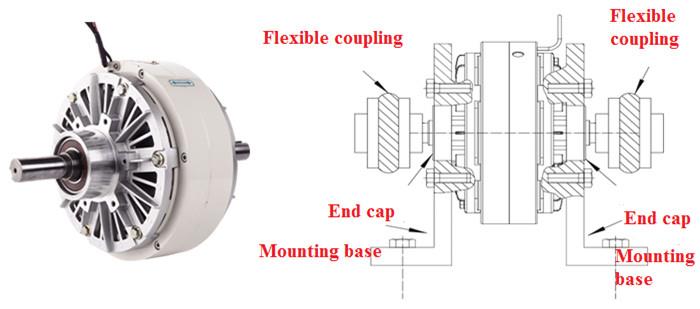

Magnetic powder clutch is easy to install

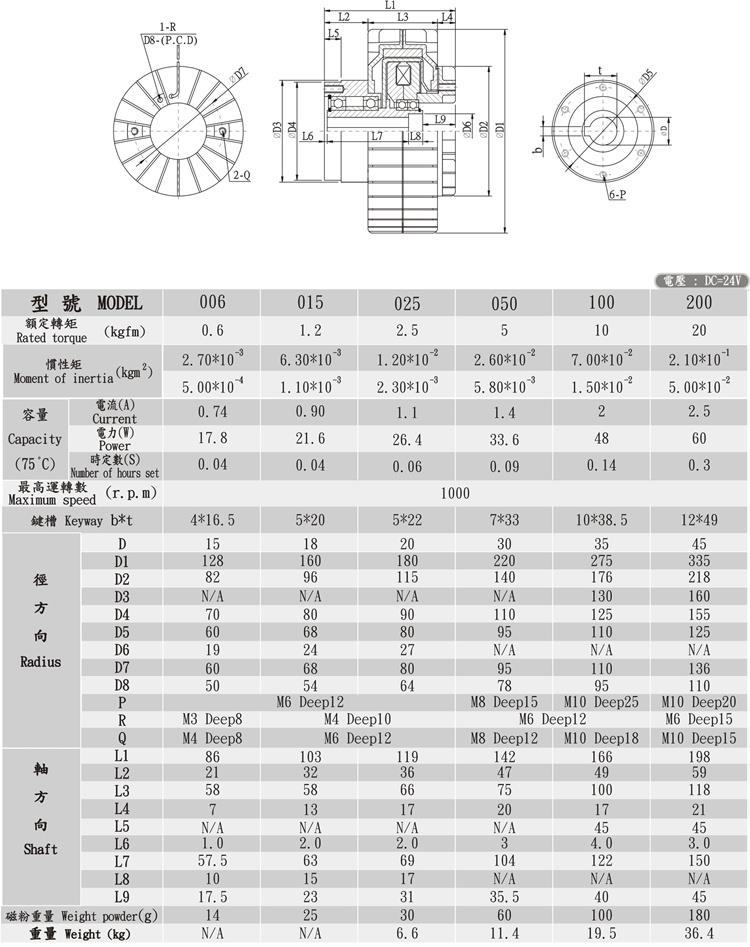

The maximum surface temperature caused by the magnetic powder brake after continuous operation is less than 90 degrees during operation. When the value exceeds this value, the durability will be greatly reduced. The magnetic powder brake is formed by combining the input shaft of the transmission unit and the output shaft of the driven unit. Therefore, the space between the two groups of cells is filled with granular magnetic powder. If the structure of the magnetic powder brake must be installed in the reverse direction of the shaft, the magnetic powder brake must be used below 1000R/MIN. The input shaft and the output shaft are installed in reverse. If this happens, the machine will idle for a long time, and the magnetic powder will be stirred, which will greatly shorten the service life of the magnetic powder brake.

The magnetic powder clutch is easy to install and has a long service life. It has a strong cast iron casing and few moving parts. The magnetic powder clutch increases with the current, the magnetic field becomes stronger, and the connection is strengthened. The magnetic powder clutch is a simple and durable device. The magnetic powder of the magnetic powder clutch is located outside the rotor. Between the diameter and the inner diameter of the drive cylinder, when there is no current in the magnetic powder clutch coil, the loose particles are loosely scattered between the rotor and the drive cylinder. When the coil is energized, the magnetic powder clutch generates a magnetic field in the stator region, and the magnetic powder along the magnetic field line Arrange, connect the rotor and the drive cylinder.

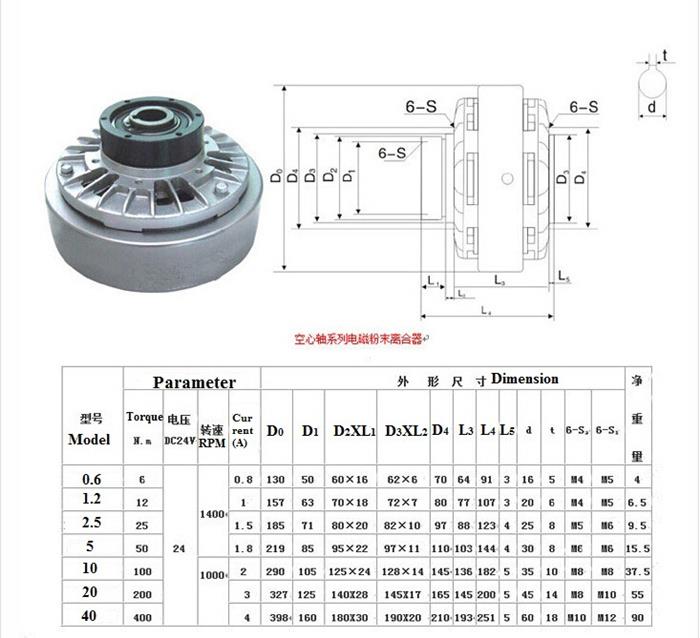

PRE-A Double Shaft Magnetic Powder Clutch

PRE-A1 Hollow Shaft Shell Rotating Magnetic Powder Clutch

PRE-A2 Hollow Shaft Inner Shell Rotating Magnetic Powder Clutch

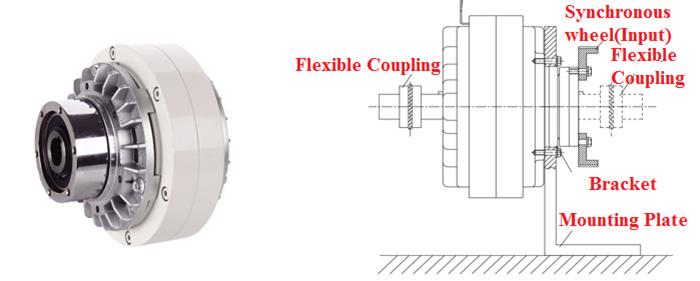

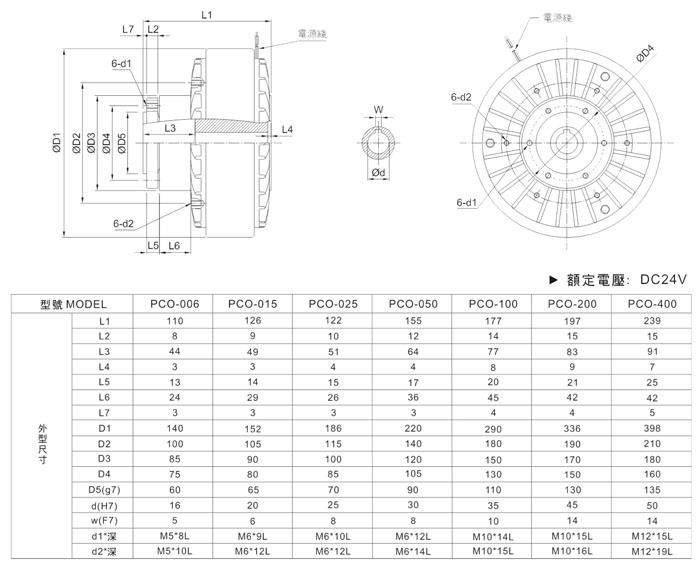

POC rotating magnetic powder clutch

The Schematic Diagram of powder clutch,tension control, web guide system and other parts on equipment.

Magnetic powder clutch must be cleaned before installation

The magnetic powder clutch must be cleaned before installation to remove rust and debris. When the wet magnetic powder clutch is working, it is necessary to add lubricating oil between the friction plates. The lubrication method is

(1) partial oil lubrication;

(2) oil bath lubrication, the part immersed in the oil is about 5 times the volume of the magnetic powder clutch;

(3) The shaft is supplied with oil for lubrication. The shaft oil supply method should be adopted for high speed and high frequency operation.

The magnetic powder clutch can be installed coaxially or in a split shaft. The axial direction must be fixed. The active part and the driven part are not allowed to have axial sway. When the split shaft is installed, the coaxial part between the active part and the driven part is coaxial. Should not be greater than 0.lmm.

When the toothed magnetic powder clutch is installed, it must ensure a certain gap between the teeth of the magnetic powder clutch face, so that there is no grinding phenomenon when idling, but it should not be greater than δ value.

The magnetic powder clutch and brake are Class B insulation, and the normal temperature rise is 40 °C. The operating temperature at the limit heat balance is not allowed to overspeed 100 ° C, otherwise the coil and the friction part are prone to damage.

The power supply and control circuit, the magnetic powder clutch power supply is 24 VDC. The magnetic powder clutch is obtained by three-phase or single-phase AC voltage through step-down and full-wave rectification (or bridge rectification). The power required for no voltage regulation and flat wave is large enough, and a half-wave rectified power supply is not allowed.

Slippery phenomenon of the moving surface of the magnetic powder clutch

Magnetic powder brakes are now widely used in papermaking, printing, plastics, rubber, textile, printing and dyeing, wire and cable, metallurgy, tablet presses and other related winding and winding tension control, magnetic powder brakes in the power supply situation The new transmission component that forms a magnetic powder chain to transmit torque is mainly composed of an inner rotor, an outer rotor, an excitation coil and a magnetic powder.

When the coil is not energized, the active rotor rotates. Due to the centrifugal force, the magnetic powder is clamped on the inner wall of the active rotor. There is no contact between the magnetic powder and the driven rotor. The active rotor is idling, and the magnetic powder brake generates electromagnetic field after being connected to the DC power supply. The working medium magnetic powder forms a magnetic powder chain under the action of magnetic lines of force, and connects the inner rotor and the outer rotor to achieve the purpose of transmitting and braking torque.

The slip phenomenon of the moving surface of the magnetic powder clutch occurs in the friction mode, but it does not occur here, and the connection sound is not emitted, so the operation is quite quiet. The magnetic powder clutch uses the magnetic powder with excellent heat resistance and is ideally used. The cooling method can be used with peace of mind even in the case of a too severe continuous sliding operation. Since the static friction coefficient and the dynamic friction coefficient are almost the same, the magnetic powder clutch does not oscillate when fully connected, and can be used to increase or decrease the load.

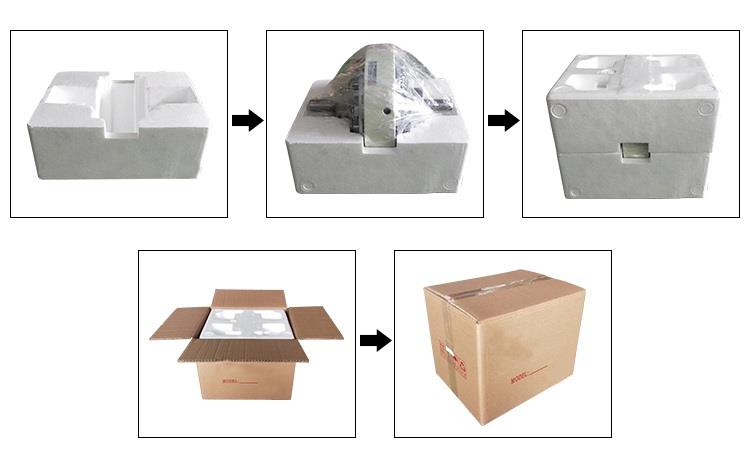

Packing

Order Details

Item Name | Magnetic Powder Clutch |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Weight | According to different models |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: magnetic slip clutch, China, manufacturers, suppliers, factory, quotation, pricelist, buy