Particle Brakes

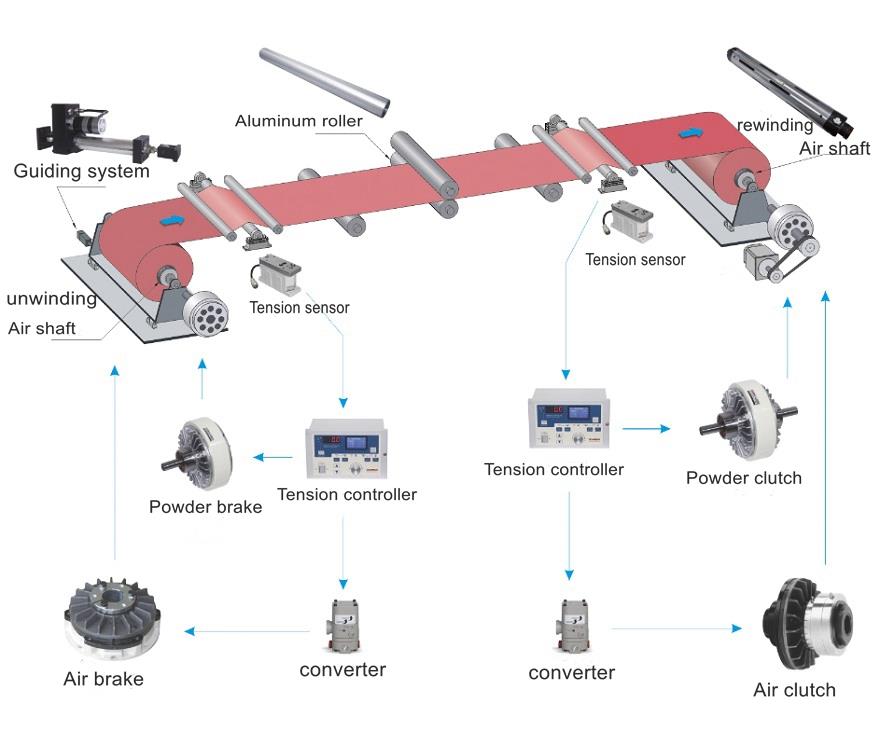

working principle 1: Magnetic powder brake(Particle Brakes) is a new type of transmission component that uses magnetic powder as a medium to form a magnetic powder chain to transmit torque under energization. It is mainly composed of inner rotor, outer rotor, excitation coil and magnetic powder....

Working Principle:

The magnetic powder brake is based on the electromagnetic principle and uses magnetic powder to transmit torque. It has the characteristics that the excitation current and the transmission torque are basically linear. It can transmit a certain torque regardless of the slip, and has the advantages of fast response, simple structure, no pollution, no noise, no impact vibration and energy saving. It is a multi-purpose, high-performance automatic control component. It has been widely used in papermaking, printing, plastics, rubber, textile, printing and dyeing, wire and cable, metallurgy, tablet presses and other unwinding and winding tension control in the coiling and processing industry. Magnetic powder brakes are also often used for dynamometer loading and braking of transmission machinery.

A.Use

1. Buffer start and stop: The start and stop of the buffer are achieved by the smoothing characteristics and the constant torque characteristics at the time of connection.

2, continuous sliding, tension control

3, torque limiter

4, high-speed response

5, power absorption

6, positioning stop

7, for analog load

B.Characteristics

2, can achieve continuous sliding operation.

3, you can get a stable torque.

4, no sounds. The slip phenomenon of the action surface occurs in the friction mode, but it does not occur here, and the connection sound is not emitted, so the operation is quite quiet.

5. The heat capacity is very large. Thanks to the use of magnetic powder with excellent heat resistance and the use of an ideal cooling method, it can be used with peace of mind even in the case of too severe continuous sliding operation.

6, can achieve smooth continuous and driving state. Since the static friction coefficient and the dynamic friction coefficient are almost the same, there is no oscillation when fully connected, and the load can be added and subtracted.

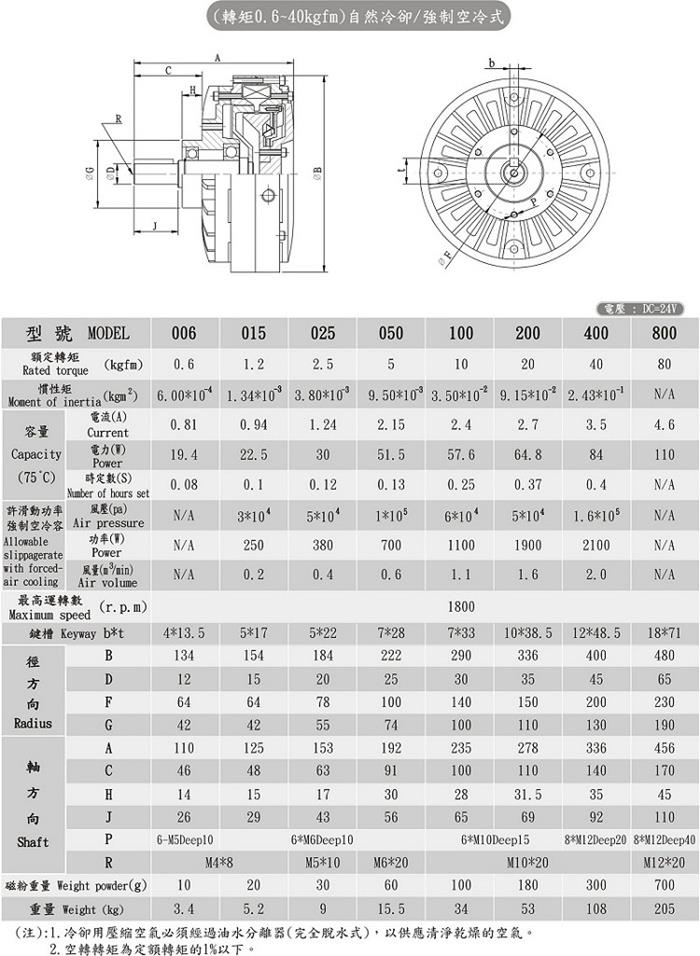

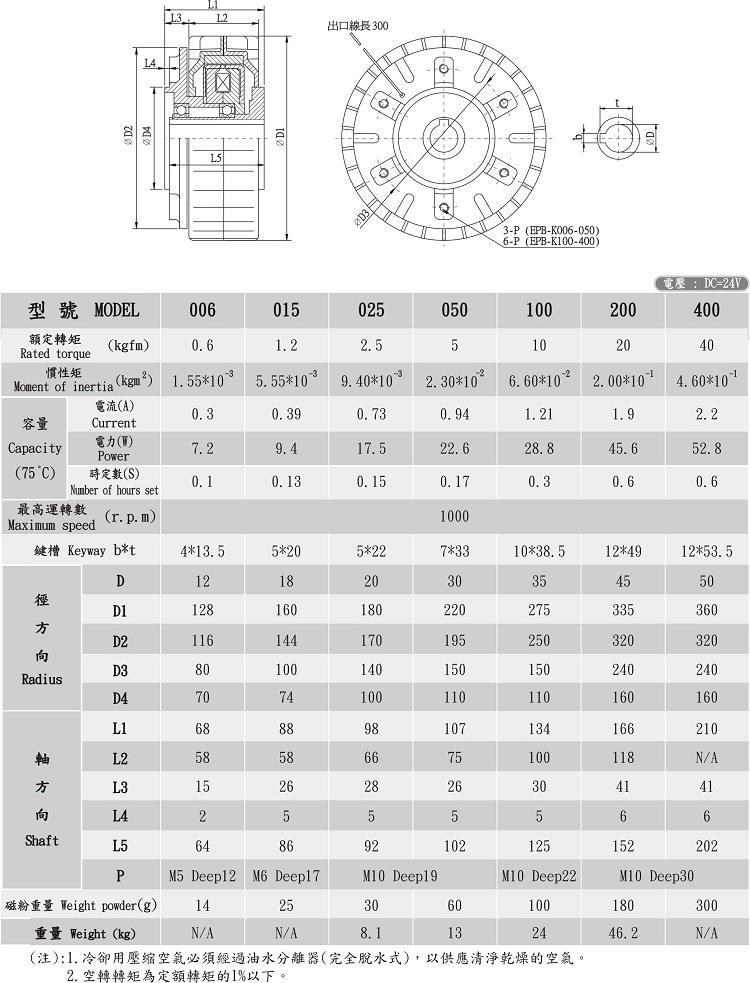

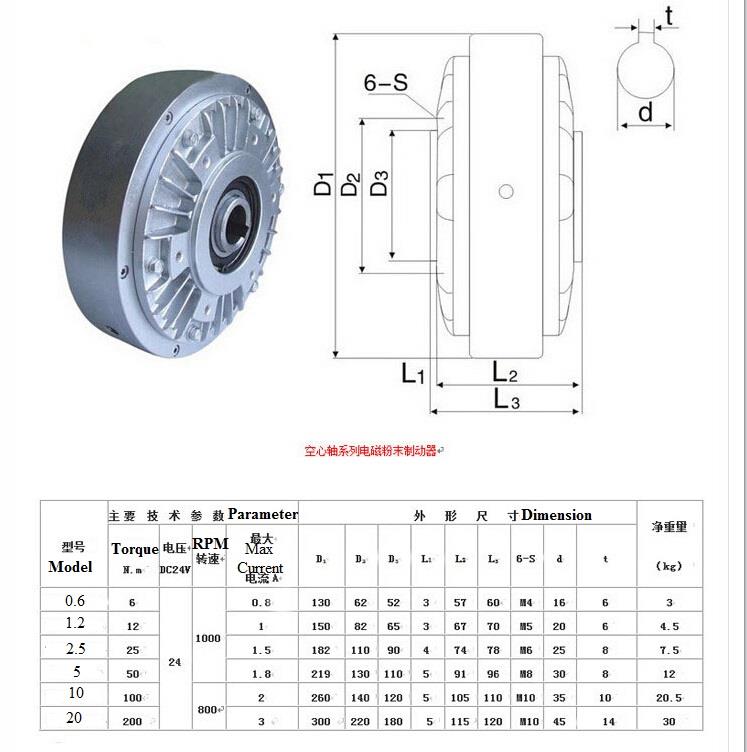

Catalogues & Model on Powder Brakes:

(a).PRE-B series

(b).PRE-B1 series

(c).PRE-B2 series

The magnetic powder brake can achieve smooth continuous and driving state, because the static friction coefficient and the dynamic friction coefficient are almost the same, so there is no oscillation when fully connected. The selection of the magnetic powder brake is generally selected based on the required maximum torque to be transmitted. The load acceleration/deceleration rate and the maximum surface temperature caused by continuous operation are 90 degrees or less during operation. When the value exceeds this value, the durability of the magnetic powder brake is greatly reduced.

The magnetic powder brakes are frequently separated, the response speed is fast, the frequency is high, and can reach 40-60 times per minute. The magnetic powder brake can be widely used in fast working conditions and high frequency occasions. The magnetic powder brake is used as an overload device for engines, motors and electric structures. The load device for torque measurement in power machinery such as hydraulic components and reducers, the magnetic powder brake has a high power amplification factor, and the magnetic powder brake can control a large transmission power with a small excitation current, and is easy to realize automatic control.

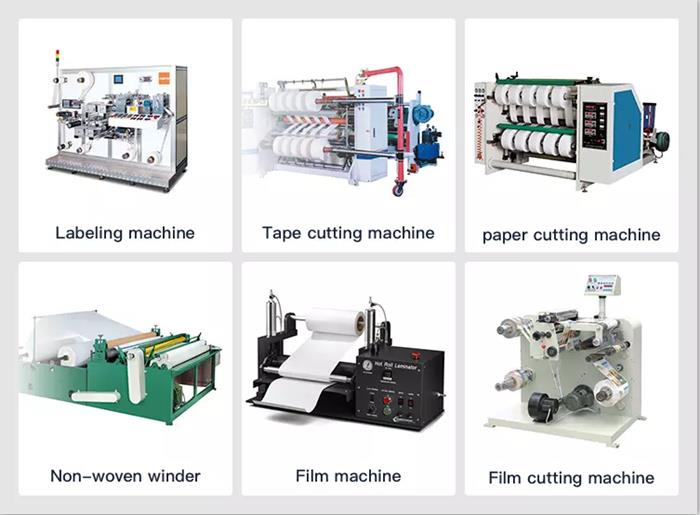

Application examples

Magnetic powder brakes are widely used, and they are roughly classified into the following types:

Startup, Brake Control This application includes normal start (clutch) and brake (brake). Since the motor is started at no load, the maximum torque of the motor can be fully utilized when starting the load. Therefore, even if the load GD2 or the starting resistance is large, it can be easily started up, and the starting process is smooth without causing a significant impact. In addition, since the motor is completely idling, it is of great benefit to improve the working conditions of the motor and prolong its service life. In addition, according to the torque characteristics, it is only necessary to adjust the excitation current to achieve the purpose of controlling the start and braking time, or changing the start and brake process curves.

Practical applications include large transmission equipment, walking cranes, large blowers, axial fans, air compressors, cement kilns, paper machines, rotary impact machines, rolling, rolling machines, wire drawing machines, large textiles, printing and dyeing, printing. Machinery, as well as the inching and operation of various industrial machinery.

Packing Pictures:

Order Details

Item Name | Particle Brakes/ Magnetic Powder Brake |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Weight | According to different models |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: particle brakes, China, manufacturers, suppliers, factory, quotation, pricelist, buy