Precision Sensor

The most advanced HCCD vision sensor technology to directly analyze the pattern in the coil material, extract the lines and edges in the image and automatically track it, and easily complete the chasing and chasing applications.

Since the objects in the textile processing process are various fibers or yarns, they are a flexible object that is easily deformed by an external force. Therefore, in order to detect changes in some parameters during processing, if a normal contact sensor is used, the detection result may have an error due to contact, and the photoelectric detection is non-contact, which does not change the original state of the yarn. Photoelectric sensor is a device that converts the amount of photoelectric energy into electric quantity. It converts non-electricity such as yarn, yarn defect, etc. into a change in electric quantity, thereby realizing detection of these non-electric quantities, because the photoelectric sensor is a non-contact measurement. It makes it widely used in textile production.

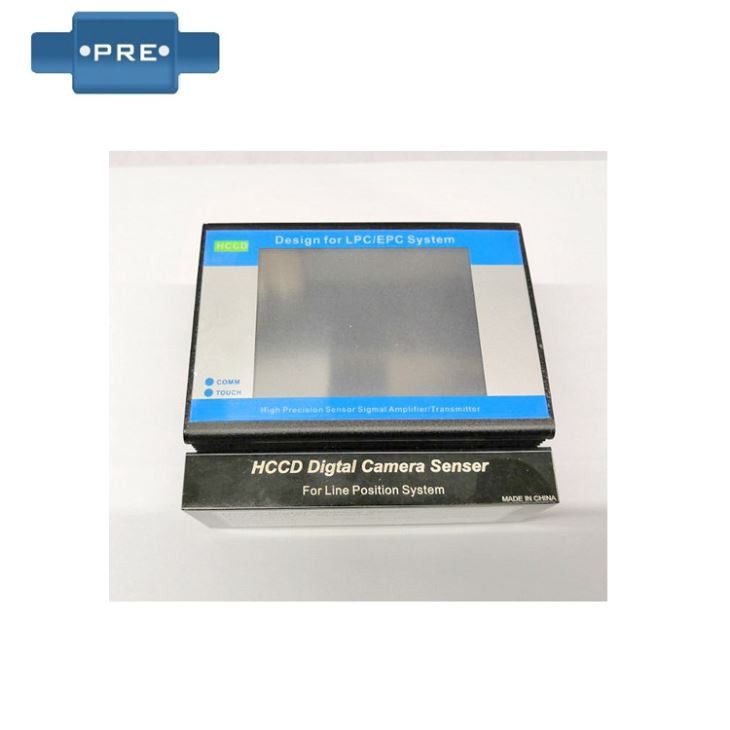

Among them, the HCCD camera sensor is commonly used. The HCCD image sensor converts the optical image projected onto the photosensitive unit into an electrical image "image" by using the photoelectric conversion function of the photosensitive unit, that is, converting the spatial distribution of the light intensity into a spatial distribution of charge packets of different sizes proportional to the light intensity. . Then, using the shift function of the shift register, these charge packets are read and output under the control of the clock pulse to form a series of timing pulse sequences with different amplitudes.

Features

1. High precision

a. Accuracy: 0.02mm

b. The finest trace: 0.2mm

c. Detection range: 20mm

2. High speed

Reaction time: 2ms

3. High stability

Full metal housing, high-speed digital communication to ensure freedom from outside interference

4. Powerful performance

Can chase and chase

Combined with computer image processing technology, it can produce digital camera sensors with minimal distortion, which is very suitable for digital camera, online detection and image recognition. In addition, it has many advantages such as small size, light weight, high integration, high resolution, low power consumption, high impact resistance and strong electromagnetic interference resistance.

The rating of cotton is mainly based on the characteristics of cotton color, impurity content, moisture, fiber length, etc. At present, the domestic cotton grade evaluation is still done manually. This kind of judgment is related to the level of the inspector, proficiency, working status and other factors. Can not be objectively evaluated. The cotton grade assessment directly affects the interests of cotton farmers, cotton companies, and mills. This problem can be solved by using photoelectric fiber test equipment.

The HCCD camera collects the image of the sample cotton, extracts the image features of the cotton by digital processing technology, obtains the color, impurity content and fiber length of the cotton, and establishes a fuzzy classifier model to classify the cotton. Achieve an objective and unified evaluation of cotton, so that cotton grading meets the requirements of automatic, continuous, fast and accurate. Light-guided thermal inspection manufacturers believe that the use of optoelectronic technology can also obtain information that many human eyes cannot read. It can produce more indicators describing cotton characteristics, providing a reliable basis for the rational use of cotton and scientific cotton blending.

Application

Order Details

Item Name | Electric Eye HCCD Sensor |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Packing Size | 15cm*10cm*10cm,2kg/pc |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: precision sensor, China, manufacturers, suppliers, factory, quotation, pricelist, buy