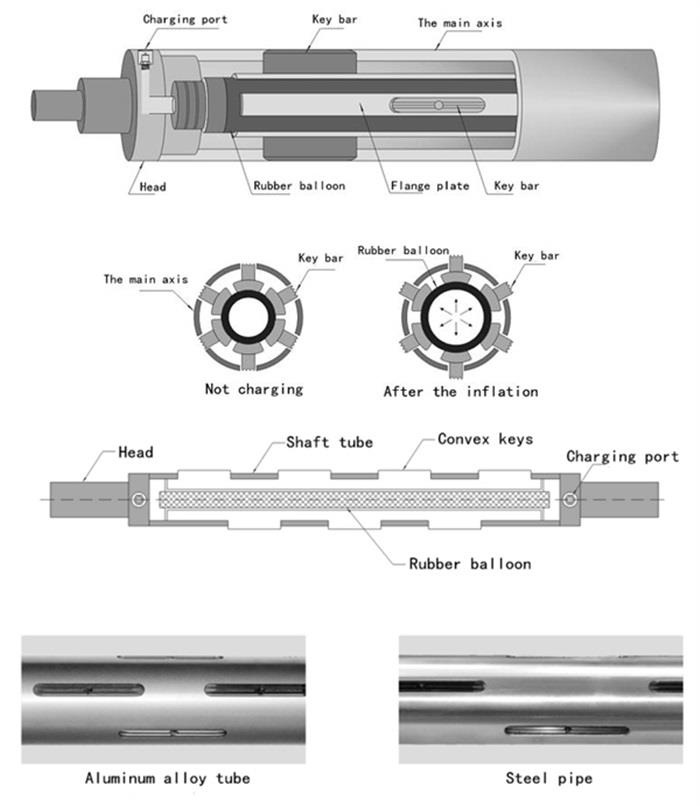

Rewinding Shaft

Inflatable shaft specifications: There are a variety of, including 1 inch, 1.5 inch, 2 inch, 2.5 inch, 3 inch, 6 inch, 8 inch, 10 inch, 12 inch, etc., according to the demand can be processed to produce different specifications of the inflatable shaft . Uses: The air-expansion shaft has a wide...

Inflatable shaft specifications: There are a variety of, including 1

inch, 1.5 inch, 2 inch, 2.5 inch, 3 inch, 6 inch, 8 inch, 10 inch, 12

inch, etc., according to the demand can be processed to produce

different specifications of the inflatable shaft .

Uses:

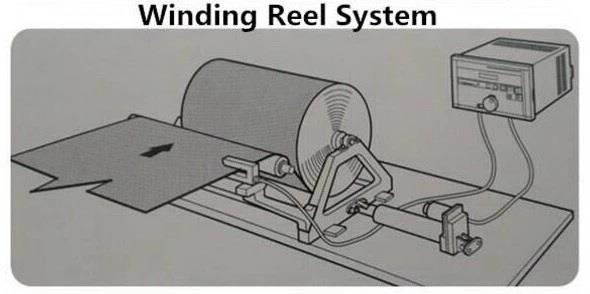

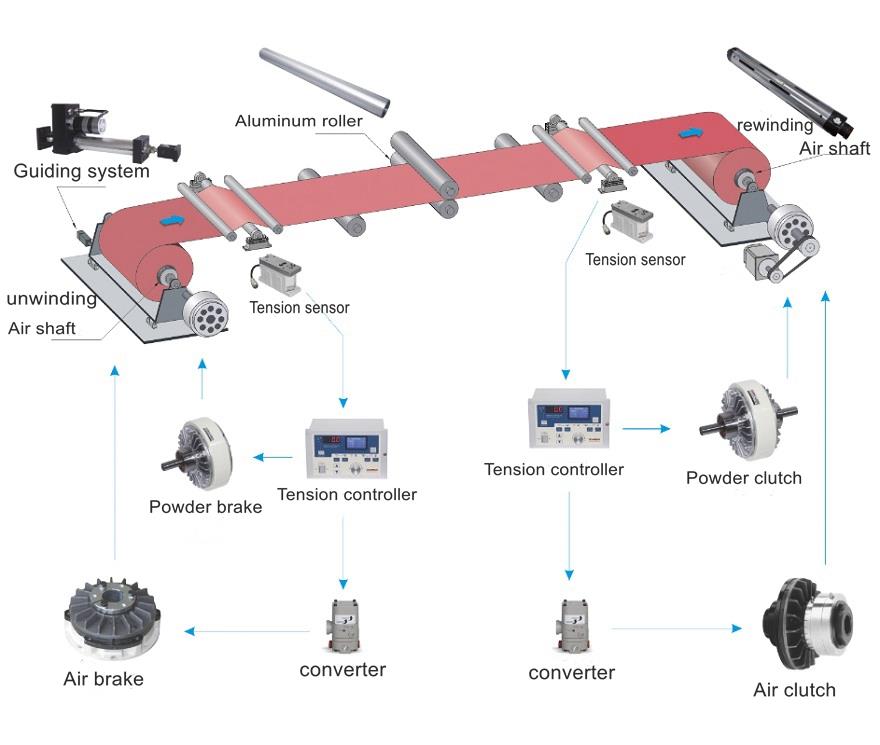

The

air-expansion shaft has a wide range of applications. For machines with

winding, unwinding and slitting, the air-expansion shaft can be applied,

even in the light metal industry. Such as: the inflation shaft is

mainly suitable for printing equipment: drying machine, flexo printing

machine, gravure machine, trademark printing machine, etc.; other

machinery: coating machine, leather machine, setting machine, embossing

machine, slitting Machine, die cutting machine, rewinding machine, paper

tube machine, bag making machine, laminating machine, laminating

machine, film blowing machine, foaming machine, laminating machine,

embossing machine, paper machine, non-woven machine, Inspection machine,

bronzing machine, battery equipment, etc.

Technique parameter

Model | Inner Diameter of Paper Tube | Shaft Diameter Before Expanding | Shaft Diameter After Expanding |

1" Shaft | Φ25.4mm | Φ24.5mm | Φ27.5mm-Φ28mm |

1.5" Shaft | Φ38mm | Φ37mm | Φ41mm |

2" Shaft | Φ50mm | Φ49mm | Φ53mm |

3" Shaft | Φ76.2mm | Φ74mm-Φ74.5mm | Φ82mm |

4" Shaft | Φ102mm | Φ100mm | Φ108mm |

6" Shaft | Φ152.4mm | Φ150mm | Φ158mm |

8" Shaft | Φ203.2mm | Φ200mm | Φ210mm |

10" Shaft | Φ254mm | Φ250mm | Φ260mm |

12" Shaft | Φ304.8mm | Φ300mm | Φ312mm |

The purpose of the abnormal operation test of the inflation shaft is to improve the reliability of the system and avoid undue accidents as much as possible. The abnormal operation test can be carried out as follows:

1. External sudden power failure experiment

When the device is operated manually or automatically, no matter under any circumstances, the sudden power-off of the external can be reliably stopped, and the device can be restored to normal operation by the specified operation steps.

2. Emergency breaking test

When the device is running manually or automatically, no matter what the circumstances, for emergency disconnection operation (such as pressing the emergency stop button on the control panel), the device can be reliably stopped and the normal operation can be resumed through the specified operation steps. .

3, detection switch failure test

Consideration should be given to the possibility of system detection switch failure, especially for components that are prone to collision, interference, and safety of mechanical components, and abnormal tests should be performed on signals such as end-of-stroke detection. It must be ensured that even if a certain detection switch is defective or damaged, it still does not. A safety incident will occur.

4, actuator failure test

Consideration should be given to the possibility of system actuators being defective, especially for actuators that are prone to mechanical collisions, interference, and affect safety. Anomaly tests should be performed to ensure that even if an actuator is defective or damaged, no safety accident will occur. .

5, protection circuit action test

The possibility of the protection circuit of the gas-up shaft system should be considered, especially for protection devices such as circuit breakers and automatic switches, and abnormal tests should be carried out to ensure that the device can be reliably stopped and the specified operation is performed when the protection device operates. Steps can resume normal work.

External condition inspection item for the inflation shaft

1. Whether the incoming line power supply voltage, frequency, grounding wire and grounding resistance of the air shaft device meet the equipment requirements.

2. Is there enough space for maintenance around the equipment?

3. Whether the working environment of the air shaft device meets the working conditions of the PLC. Whether the electrical cabinet, console, and other components are installed in direct sunlight.

4. Whether there is strong vibration or other strong electromagnetic interference equipment around the equipment. If so, has the equipment been effectively damped, electromagnetically shielded and protected.

Packaging

Order Details

Item Name | Rewinding shaft |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 15-18 days after receiving the deposit |

Calculated Weight | Depend on dimension |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: rewinding shaft, China, manufacturers, suppliers, factory, quotation, pricelist, buy