Roll Forming

Brief description: Roller making requirements for aluminum guide rolls The working surface of the aluminum guide roller should be finely machined to ensure dimensional accuracy and surface roughness. The coating has anti-flaking ability to ensure that the working surface of the roller has good...

Brief description: Roller making requirements for aluminum guide rolls

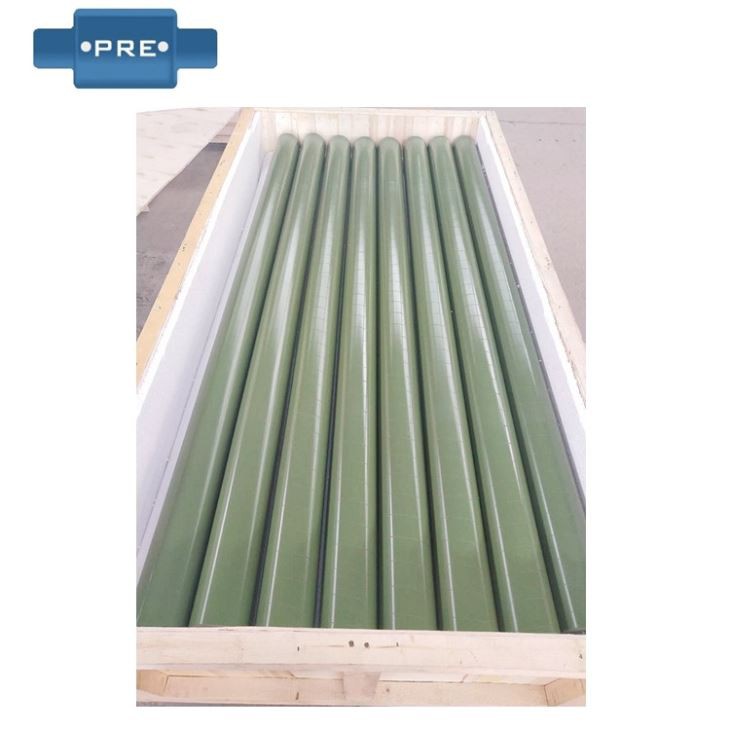

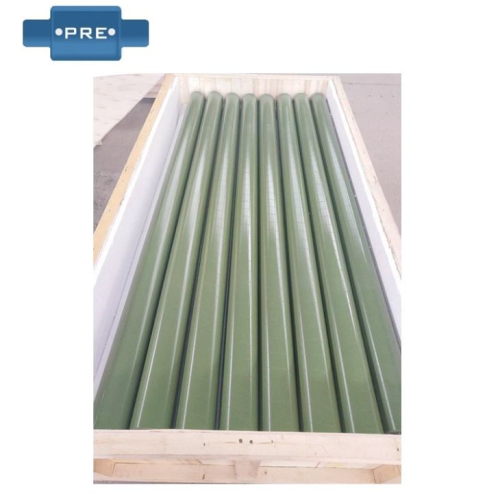

The working surface of the aluminum guide roller should be finely machined to ensure dimensional accuracy and surface roughness. The coating has anti-flaking ability to ensure that the working surface of the roller has good wear resistance and corrosion resistance.

1. The rollers of the aluminum guide rolls should be sufficiently rigid to ensure that the bending deformation does not exceed the permissible value under heavy loads.

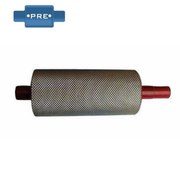

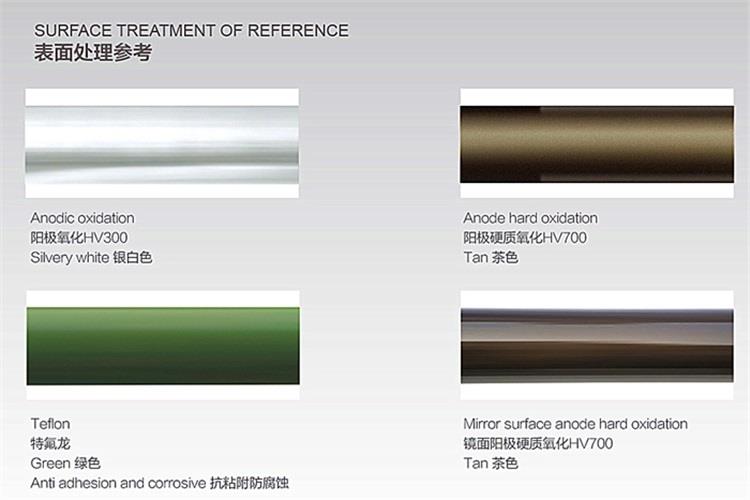

2. The surface of the roller should have sufficient hardness. It is generally required to reach above 50 degrees HRC and has strong corrosion resistance. The coating has anti-flaking ability to ensure that the working surface of the roller has good wear resistance and corrosion resistance.

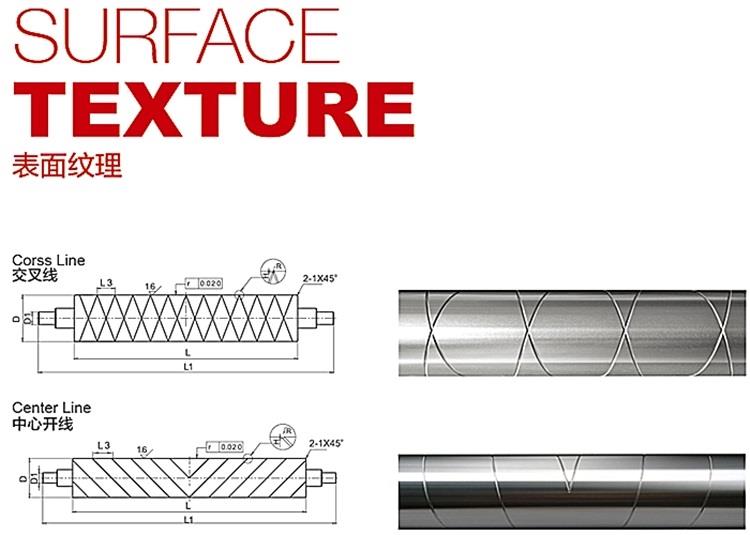

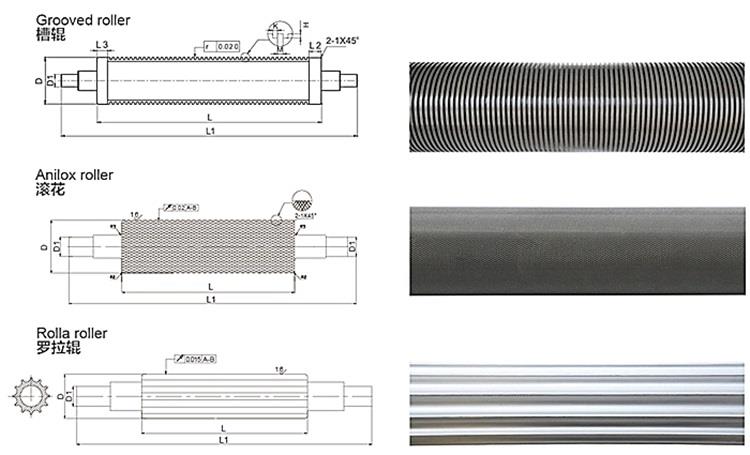

3. The working surface of the aluminum guide roller should be finely machined to ensure dimensional accuracy and surface roughness.

The roughness should be above a0.16, and there should be no pores or grooves. The wall thickness of the working surface of the roller should be uniform, otherwise the temperature of the roller surface will be uneven, which will affect the quality of the product.

4. The material of the roller should have good thermal conductivity. Usually, chilled cast iron is used. In special cases, cast steel or molybdenum-chromium alloy steel can be used to achieve rapid and uniform heating or cooling.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

The reasons for the roll print are:

(1) knife flowers remain after processing of the aluminum guide roll;

(2) The pressure of the exit guide is too large;

(3) The aluminum guide roller or straightening roller is bruised by foreign objects;

(4) Straightening roll hole type curve does not match the product.

Ways to prevent and eliminate aluminum roller roll printing are:

(1) Improve the surface hardness and processing quality of the aluminum guide roll and the straightening roll;

(2) Correctly install the exit guide;

(3) Reasonable design of straightening roller hole type.

Application

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: roll forming, China, manufacturers, suppliers, factory, quotation, pricelist, buy