How To Measure Tension

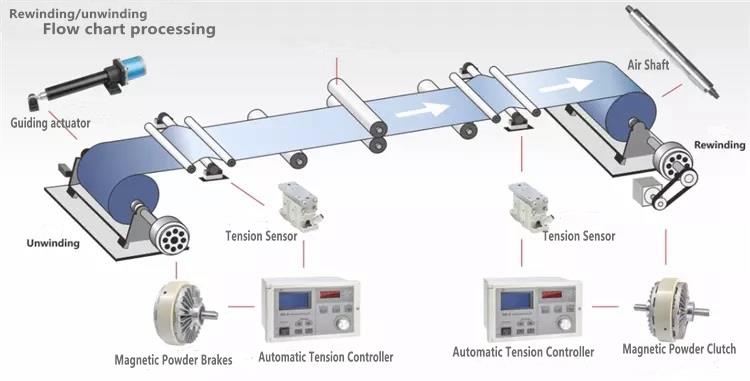

Automatic tension controller works: * Coil static type magnetic powder clutch and magnetic powder brake are automatic devices that control the input current to change the output transition. * When the coil is not energized, the input shaft rotates, and the magnetic powder is pressed against the...

Automatic tension controller works:

* Coil static type magnetic powder clutch and magnetic powder brake are automatic devices that control the input current to change the output transition.

* When the coil is not energized, the input shaft rotates, and the magnetic powder is pressed against the inner wall of the clamp ring under the action of centrifugal force, and the output shaft is not in contact with the input shaft. At this time, it is in an idling state.

* When the coil is energized, the magnetic powder generates a magnetic flux under the action of the magnetic force line, so that the output shaft and the input shaft become a rigid body and rotate, and a slip occurs when overloaded, and this is an operating state. Thereby achieving the purpose of transmitting torque.

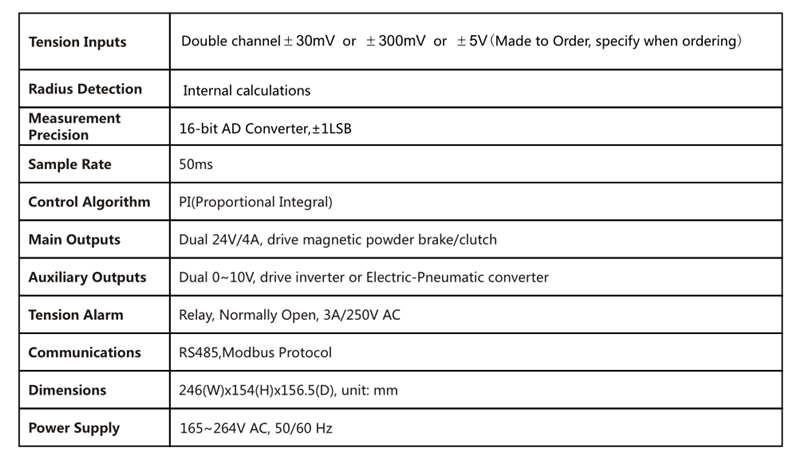

Automatic Tension Controller KTC-828A

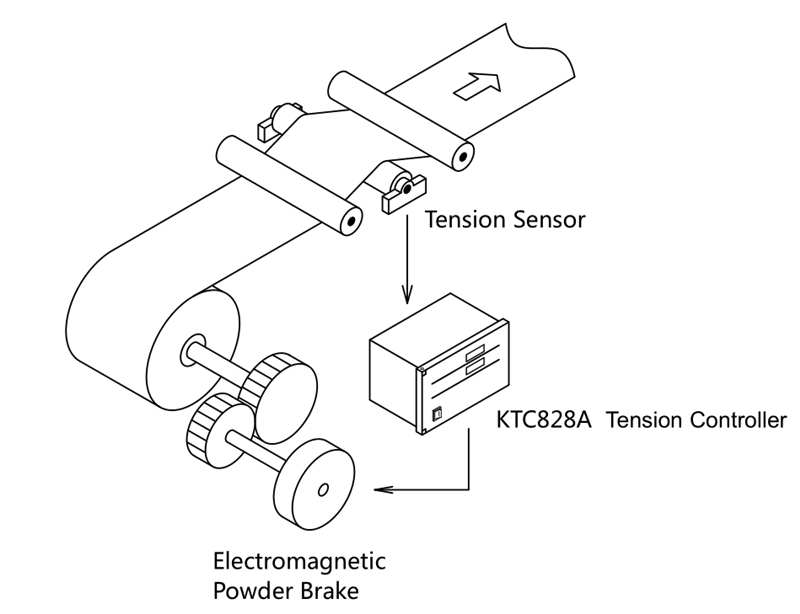

Working Principle:

Characteristics

1. Torque and excitation current are proportional to the specified torque range and can be used as a linear adjustment element.

2. The output torque is constant because the magnitude of the torque depends only on the magnitude of the excitation current, regardless of the slip speed.

3. Frequent separation, fast response, high frequency, 40-60 times per minute, can be widely used in fast working conditions and high frequency occasions.

4. The power amplification factor is high, and a large excitation current can be used to control a large transmission power, which is easy to realize automatic control.

5. Smooth operation, no vibration, no impact, no noise in starting, running, braking state.

6. Overload protection, in the case of torque overload, automatic slip operation acts as overload protection.

7. Small size and light weight. Easy to install and long service life.

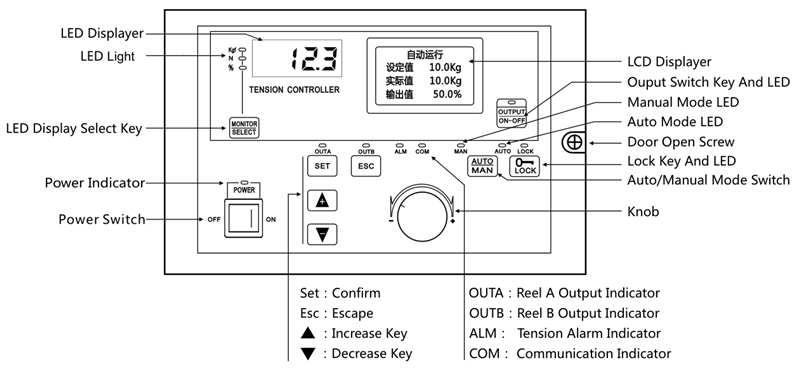

Operating Panel:

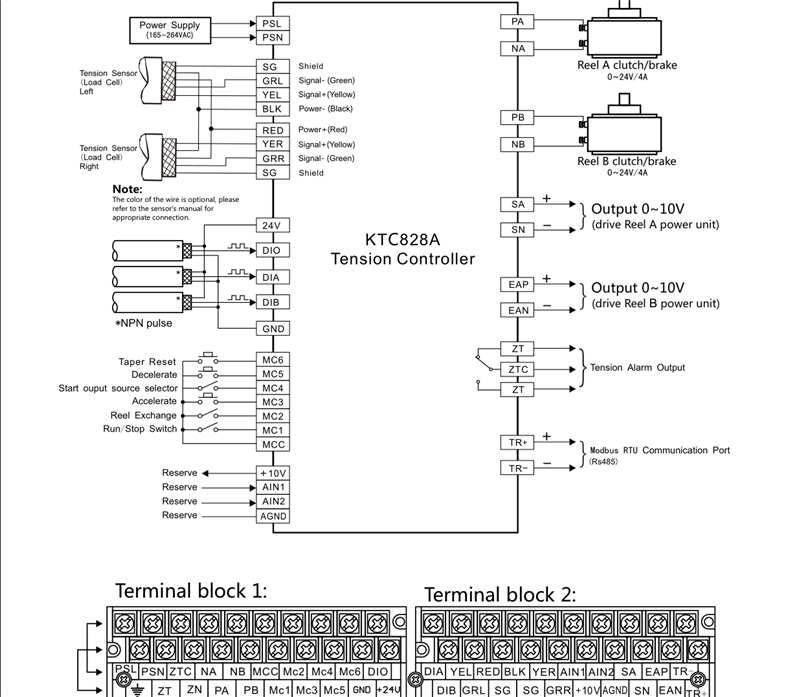

Wiring Diagram:

What are the detection methods of the automatic tension controller?

1. Float arm (Dancer Arm) tension detection method: it is an indirect tension detection method, which is essentially a position control. When the tension of the automatic tension controller is stable, the tension on the belt is balanced with the cylinder force. , so that the floating roller is in the center position. When the tension changes, the balance between the tension and the cylinder force is destroyed, and the position of the floating roller will rise or fall. At this time, the swing lever will rotate around the M point and drive the float roller potentiometer to rotate together. In this way, the float roller potentiometer accurately detects the change of the position of the floating roller, and it will feed back the tension controller with the position signal, and the controller calculates and outputs a control signal to control the servo drive system to perform the deviation correction. Then the float rolls return to their original equilibrium position. Since the floating roller type tension detecting device itself is an energy storage structure, it has a good absorption buffering effect on a wide range of tension jumps by using its own residual action, and can also reduce the eccentricity (ellipse) and speed of the coil. The effect of changes on tension. This system requires a small cylinder friction coefficient, fast response, and stable air supply. The weight of the float roller and the swing bar should be light and the rotation should be flexible.

2. Tension sensor (load cell) measurement method: It is a direct detection of the tension, closely combined with the machine, no detection method of moving parts. Usually two sensors are paired and mounted on the end shafts on both sides of the detection guide roller. The strip applies a load to the guide roller to cause displacement or deformation of the sensor sensor of the tension controller, thereby detecting the actual tension value, and converting the tension data into a tension signal for feedback to the tension controller. Realize tension closed loop control. There are many types of elastic sensors on the market, such as leaf spring type micro-displacement tension sensors, strain gauge tension sensors (such as Italian RE CF series) and pressure magnetic tension sensors (such as Italian RE CB pillow series). The advantage is that the detection range is wide, the response speed is fast, and the linearity is good. The disadvantage is that the peak of the tension cannot be absorbed, and the mechanical acceleration and deceleration is difficult to handle, and it is not easy to realize high-speed switching of the volume. Therefore, when the tension controller system in equilibrium is subjected to strong interference, the system can't react in an instant, and the amplitude of the tension change on the strip will be large, which is unfavorable for the tension control to re-enter the equilibrium state as soon as possible.

3. Floating roller/feedback composite tension detection mode: It can simultaneously detect the floating roller position signal output by the floating roller potentiometer and the tension signal output by the tension sensor, thereby providing higher precision tension control to the system. Its characteristics are: it not only has the absorption or buffering function of the floating roller control for a wide range of tension jump, but also has a good buffering and smoothing effect on the machine acceleration and deceleration, and it is easy to realize high-speed switching of the volume. High precision and high repeatability of closed-loop control of tension sensor.

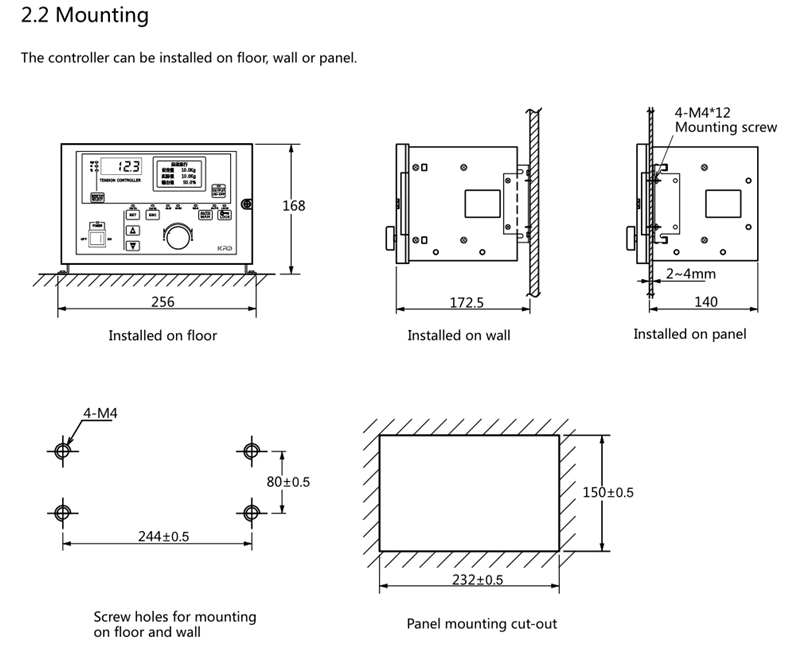

Order Details

Item Name | KTC-828A Automatic Tension Controller |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 2 days after receiving the deposit |

Calculated Packing Size | 20cm*15cm*15cm,2kg/pc |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: how to measure tension, China, manufacturers, suppliers, factory, quotation, pricelist, buy