Shore Hardness Polyurethane Rubber Coating Roller

1. Features of rubber roller 1)Ozone and Chemical resistance 2)Anti-aging, good flexibility, good elasticity 3)Excellent oil resistance 4)Clean and healthy for many food and medical applications 2. Specification of rubber rollers What are the benefits and traits of rubber rollers of various...

1. Features of rubber roller

1)Ozone and Chemical resistance

2)Anti-aging, good flexibility, good elasticity

3)Excellent oil resistance

4)Clean and healthy for many food and medical applications

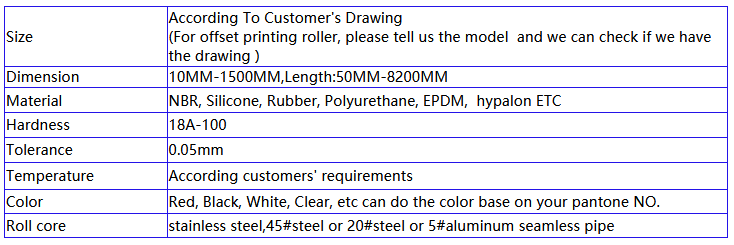

2. Specification of rubber rollers

What are the benefits and traits of rubber rollers of various materials

Commonly may be divided into the subsequent sorts:

1. ethylene propylene rubber roller: warmth resistance, aging resistance, balance, extraordinary climate resistance, ozone resistance, and fantastic water resistance and chemical resistance. can be utilized in printing and dyeing, paper making, and so forth.

2. nitrile rubber curler: it has top notch abrasion resistance, oil resistance, getting old resistance, and warmth resistance. printing rollers, printing and dyeing rollers, and papermaking rollers are greater commonplace. typically used in printing, printing and dyeing, papermaking, packaging, chemical fiber, plastic processing and different device and different touch oil and aliphatic hydrocarbon solvents.

3. carbon fiber curler: this kind of rubber roller is usually light in weight, high in energy and high temperature resistance. it is extensively used in special paintings along with extensive movie.

Four. butyl rubber curler: excessive chemical solvent resistance, precise heat resistance (170 ℃), superb acid and alkali resistance, suitable for colorful printing machinery, tanning equipment, coating system, and so on. this material can be covered to make leather-based rolls, printing rolls, coating rolls, and many others.

5. silicone rubber curler: it has excessive temperature resistance, excessive stress resistance, ozone resistance, chemical laziness and non-adhesion to plastics, and is used for processing hot-adhesive merchandise along with polyethylene calendering, embossing, printing and dyeing, and movies and fabric lined adhesives, plastic compounding, corona remedy and different machinery, extensively utilized as sugar manufacturing and packaging gadget launch curler and non-woven fabric manufacturing.

6. neoprene roller: this kind of rubber curler has extremely good abrasion resistance, excessive fireplace resistance, oil resistance, ageing resistance, desirable warmness resistance, and acid and alkali resistance, and may be made into printing rubber rollers and iron printing rollers. , tanning roller, coating curler, etc. used for revealed board corrosion system, plastic, tanning, printing, meals printing iron, general coating device and different equipment.

7. polyurethane rubber curler: hardness 30 ° ~ 100 °, with extraordinarily high mechanical power and abrasion resistance, corrosion resistance, growing older resistance and oil resistance. it's miles regularly used in metallurgy enterprise, papermaking, paper sprucing, chemical fiber, wood processing, plastic processing, printing iron coating and different machinery. excessive-grade printing rubber roller, iron printing curler, metallurgical roller are usually used.

8. ethylene-propylene rubber curler: it has first rate resistance to ozone aging and climate resistance. it can paintings for a long time at the temperature of -sixty five ℃ -a hundred and forty ℃. the insulation feature is splendid. the rubber curler may be utilized in plastic printing machinery and leather-based making. fashionable fields consisting of equipment. tannery rollers and printing rubber rollers are more usually used.

Nine. fluorine rubber curler: it has very excessive heat resistance, oil resistance, acid and alkali resistance, air permeability, electric insulation, getting old resistance, flame resistance, put on resistance and different capabilities. it's also suitable for special coating equipment. .

10. herbal rubber rollers: those rubber rollers have brilliant elasticity and mechanical strength, and desirable alkali resistance. they are often used in papermaking leather, textile, packaging and different device. roll.

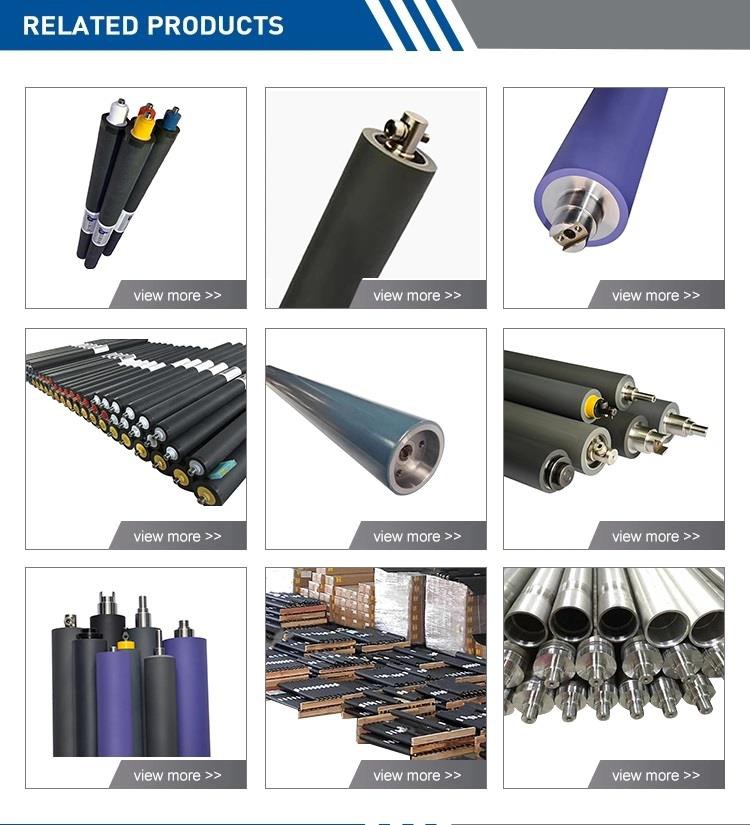

Rubber roller application in all industries

Packaging

Order Details

Item Name | Rubber coating roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: shore hardness polyurethane rubber coating roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy