Precision Roll Grinding Silicone Roller

Features of silicone roller: 1. Excellent high and low temperature resistance, working temperature range -100 to 350 degrees. Excellent resistance to ozone aging, oxygen aging, light aging and weathering. The performance of the silicone roller in the free state for several years has not changed,...

Features of silicone roller:

1. Excellent high and low temperature resistance, working temperature range -100 to 350 degrees. Excellent resistance to ozone aging, oxygen aging, light aging and weathering. The performance of the silicone roller in the free state for several years has not changed, so it is convenient to use the silicone roller in many industries.

2, excellent electrical insulation properties, the electrical insulation properties of silicone roller changes little when the moisture, frequency changes or temperature rise, the silica formed after combustion is still an insulator, so in some environments requiring insulation, silica gel The roller is also used more frequently. In addition, the silica gel has a small carbon atom in the molecular structure and does not use carbon black as a filler, so that it is less likely to be scorched during arc discharge, and thus it is very reliable for use in high pressure applications. Its corona resistance and arc resistance are extremely good, the corona life is 1000 times that of polytetrachloroethylene, and the arc life is 20 times that of fluororubber.

3. The silicone roller has special surface properties and physiological inertness. The surface energy of the silicone roller is lower than that of most organic materials. Therefore, it has low hygroscopicity and is immersed in water for a long time. Its water absorption is only 1%, the physical and mechanical properties are reduced, and the mildew resistance is good. Therefore, silica gel is also used for underwater operations or humid environments. In addition, the silicone roller does not stick to many materials and can act as an insulator.

4, silicone rubber tasteless and non-toxic has no adverse effects on the human body, the body reacts slightly, with excellent physiological inertia and physiological aging.

5, high gas permeability, silicone roller and other polymer materials have superior gas permeability, the transmittance in the air at room temperature is 30-40 times that of natural rubber, in addition, the silicone roller also has a gas The selectivity is different for the gas permeability of different gases.

Rubber roller maintenance

The newly cast rubber roller should not be put into use immediately.

Since the internal structure of the newly cast rubber roller is not stable enough, it is easy to reduce the service life if it is put into use immediately. Therefore, the new rubber roller that has just been released should be placed for a period of time, so that the rubber roller maintains a relatively stable state after being exposed to the ambient temperature and humidity, which can increase the toughness of the colloid and thereby improve the durability.

Proper storage of idle rubber rollers.

After the rubber roller to be used should be cleaned, the plastic film is used to seal the gel and placed on the rubber roller frame. Do not stack a few pieces or place it by the wall, so as to avoid the undue loss of the gel. . During the transportation process of the used rubber roller to the processing and casting, it is forbidden to throw the chaotic pressure or heavy pressure, keep the roller core unbiased and not bent, to ensure the normal use of the roller core.

The roller head and bearing should be well lubricated.

We know that the precision of the rubber roller shaft head and bearing directly affects the effect of ink transfer and ink discharge. If the poor lubrication causes the rubber roller shaft head, the wear and clearance of the bearing will inevitably lead to the disadvantage of uneven printing ink color. At the same time, it will cause printing bar marks due to bad conditions such as jumping rubber and slip rubber. Therefore, the rubber roller shaft and the bearing should be filled with lubricating oil to prevent the normal use of the rubber roller and ensure the printing quality.

Application

Packaging

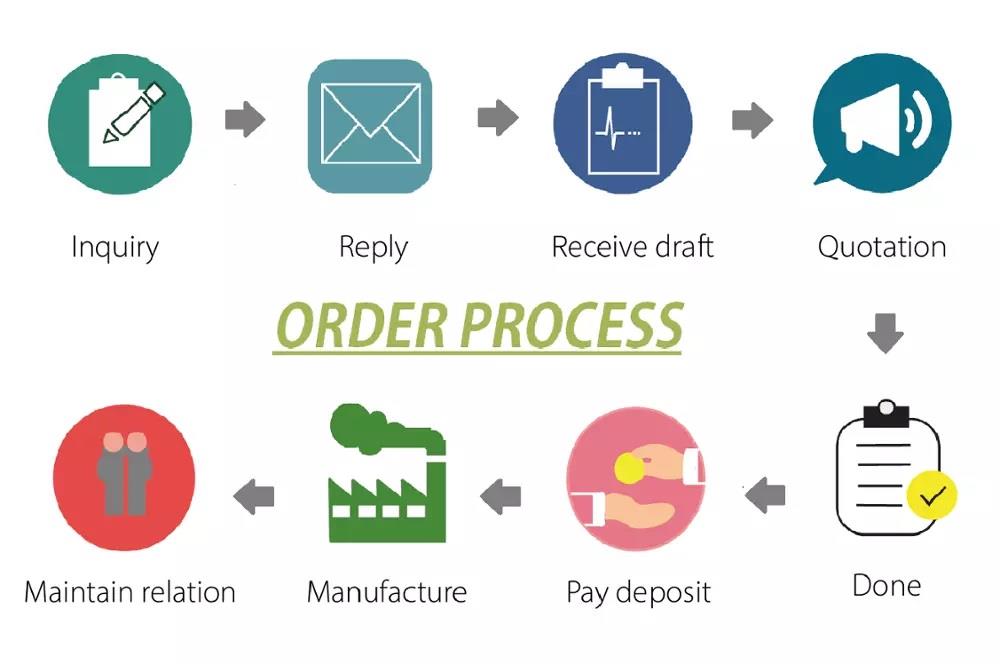

Order Details

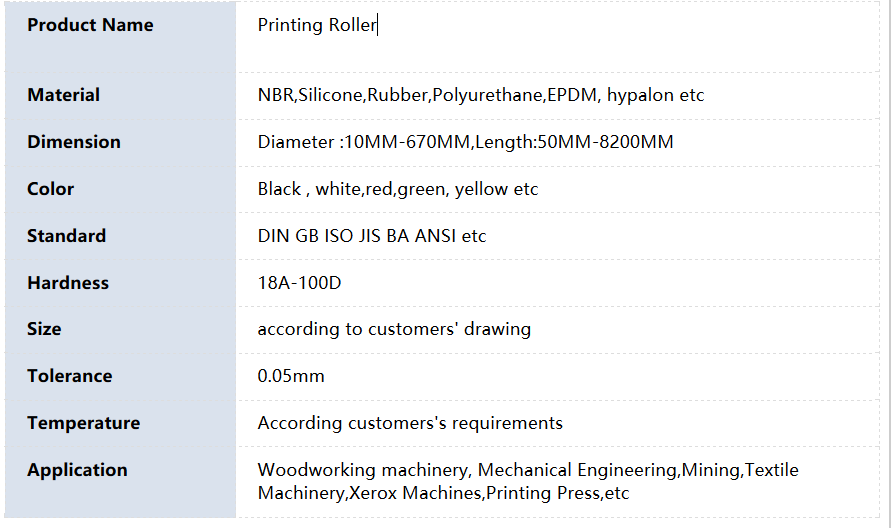

Item Name | Printing machine roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: precision roll grinding silicone roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy