High Precision Rubber Roller

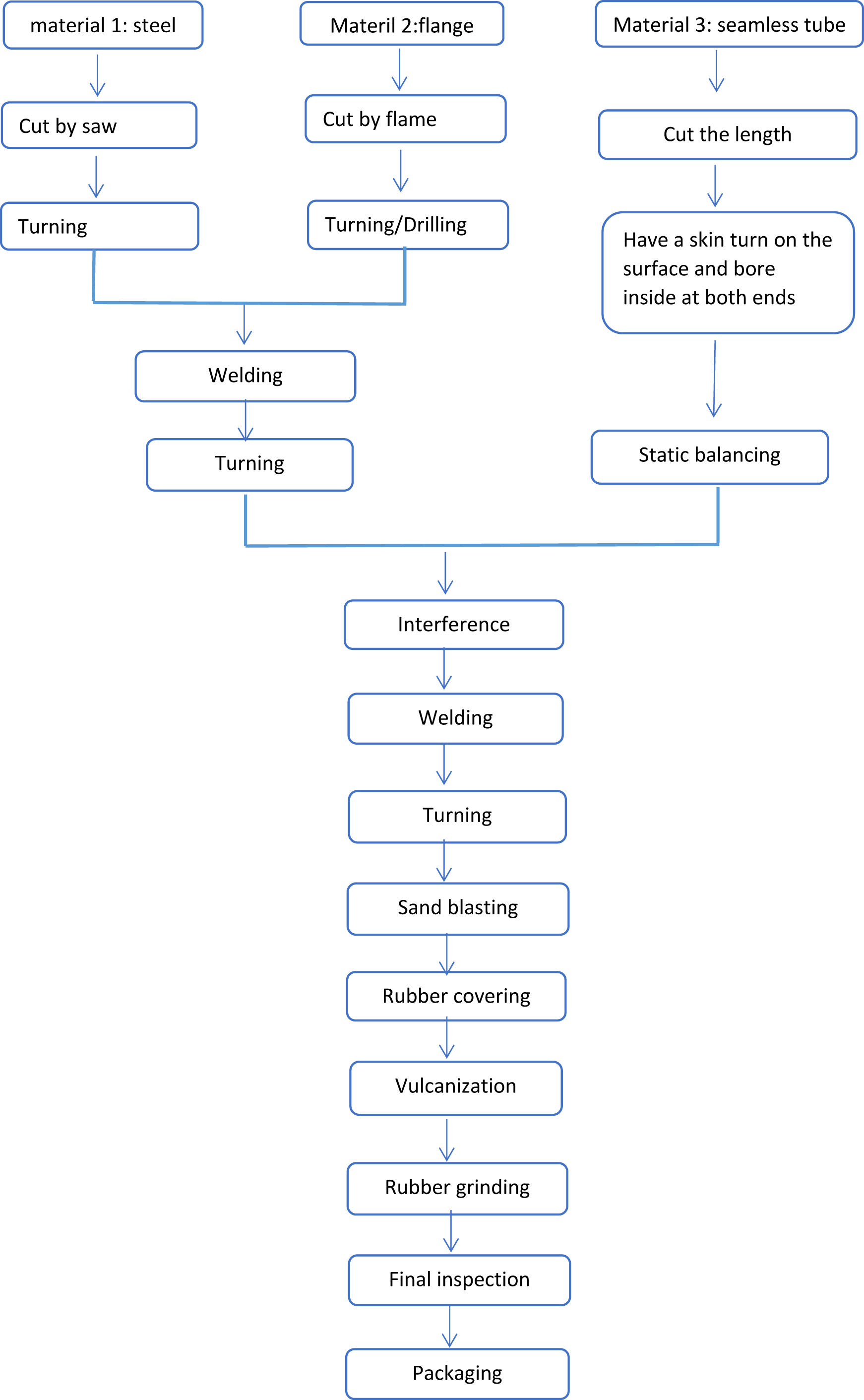

Production Process of Rubber Rollers Storage: In general, the rubber roller should be stored in a warehouse at a temperature of 10-35 ° C and a relative humidity of 50-80%. If the temperature is too high or too low, it will cause thermal cracking or thermal crosslinking of the rubber, which will...

|

Production |

Custom production |

|

Length |

Max.12,000mm |

|

Diameter |

Max.1,600mm |

|

Loading Capacity |

Max.50,000kg |

|

Rubber Type |

EPDM, NBR, SBR, PU(good wear-resistance), Silicone(for high-temp), etc. |

|

Runout |

≥0.01mm |

|

Dynamic Balance |

G2.5 |

|

Surface Roughness |

Grinding: ≤Ra0.8um |

|

Surface Hardness |

SHORE A 40-95 |

|

Application Fields |

Large format digital printer(printing rubber roller), tissue converting machinery, paper machinery(paper-making rubber roller), textile, conveyor systems (conveyor rubber roller), logistics equipment, mine and filter industry, etc. |

|

Package |

Wooden case |

Production Process of Rubber Rollers

Storage:

In general, the rubber roller should be stored in a warehouse at a temperature of 10-35 ° C and a relative humidity of 50-80%. If the temperature is too high or too low, it will cause thermal cracking or thermal crosslinking of the rubber, which will cause the rubber surface to age, harden, lose its elasticity and crack, and cause the wear resistance to decrease. In addition, if the humidity is too large, the humidity will be wet. The air will cause the roller core to absorb moisture and rust.

Because the rubber roller is covered with rubber, it should be protected from direct sunlight during transportation and storage, rain and snow immersion, and it is prohibited to touch with acid, alkali, oil and organic solvent, and it is 2m away from the radiant heat source.

Do not place under strong light and ultraviolet light. In addition to directly causing the breakage and cross-linking of rubber molecular chains, the rubber generates free radicals due to absorption of light energy, which initiates and accelerates the oxidation chain reaction process. Ultraviolet light plays a role in heating. Therefore, it is necessary to cover the rubber roller with thick paper and black plastic cloth, etc., otherwise it will cause aging, discoloration, cracking, etc. of the rubber surface, reducing the service life of the rubber roller and affecting the quality of the printed product.

When the rubber rollers are stacked in storage, they should be supported for storage in the shaft. It is strictly forbidden to stack and the distance between the rollers and the rollers should not be less than 5mm. When moving and moving, the shaft should be lifted and suspended to prevent the rubber surface from being squeezed, bumped or scratched.

If the new roller is not used temporarily, please do not open the package. Only remove the wrapping paper before installation, because the wrapping paper can protect it.

In addition, the rubber roller should be stored away from high-voltage equipment, motors and other places where ozone may be generated. Because the chemical activity of ozone is much higher than that of oxygen, the destructiveness is also large and improper storage, and it is easy to cause ozone cracking. For rubber rollers stored in the super-standard period, check for defects before use. Only when they are completely intact can they be used on the machine.

Packaging

We regard packaging as a crucial link. Careful and appropriate packaging is fairly important to ensure

the good condition and successful delivery of the rubber covered rolls.

The following represents the most common practice:

· Wrap each of the rubber feed roller with plastic.

· It is evacuated between the roller and the plastic.

· Add desiccant.

· Bubble wrap.

· Plywood case.

Order Details

|

Item Name |

Rubber roller |

|

MOQ(Minimum Order Quantity) |

1Pc |

|

Lead time |

10-15 days after receiving the deposit |

|

Calculated Weight |

Need to count |

|

Package |

Wooden Box |

|

Price Term |

EXW,FOB, CIF, etc |

|

Payment term |

TT,L/C,Western Union |

|

Country of Origin |

China |

Hot Tags: High Precision Rubber Roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy