Precision Resolution Infeed Roller

The web material (cloth, paper, film, etc.) is easy to produce wrinkles during the manufacturing and processing, if the wrinkled material enters the process of embossing, coating, printing, compounding, coiling, etc. A defective product is produced, and the flattening roller is used to move the...

The web material (cloth, paper, film, etc.) is easy to produce wrinkles during the manufacturing and processing, if the wrinkled material enters the process of embossing, coating, printing, compounding, coiling, etc. A defective product is produced, and the flattening roller is used to move the web material laterally from the center to the west side to eliminate wrinkles and to level into the next process. Our factory specializes in the production of four series of series of flattening rolls, widely used in textile, printing and dyeing, paper, plastic, printing, packaging and other fields. It can meet the flattening needs of different materials, different specifications and different use conditions.

Features:

• High line speed, low jitter, no noise

• Small torque and can withstand large pulling forces

• Good sealing performance, waterproof, acid and alkali resistant

• Safe and durable, easy to install and debug

• Unique flattening function for the substrate to appear in the middle of the tight side of the two sides or the middle of the loose side

The angle of the substrate wrapping roller should not be too large or the tension is too large, otherwise the film-based substrate may be permanently deformed, the paper substrate may be broken, and the cloth substrate may be bent in the weft direction. It is sometimes necessary to adjust the direction of the curvature in time depending on the condition of the substrate. Curved flattening rolls are widely used in textile, printing and dyeing, printing, paper making, film, packaging and other industries. They are widely used and used in large quantities.

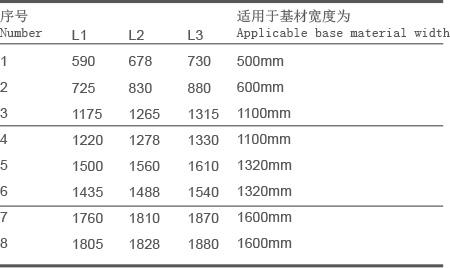

Ordering Information: Roller length, mandrel length, roll face diameter, line speed

CHARATERISTIC

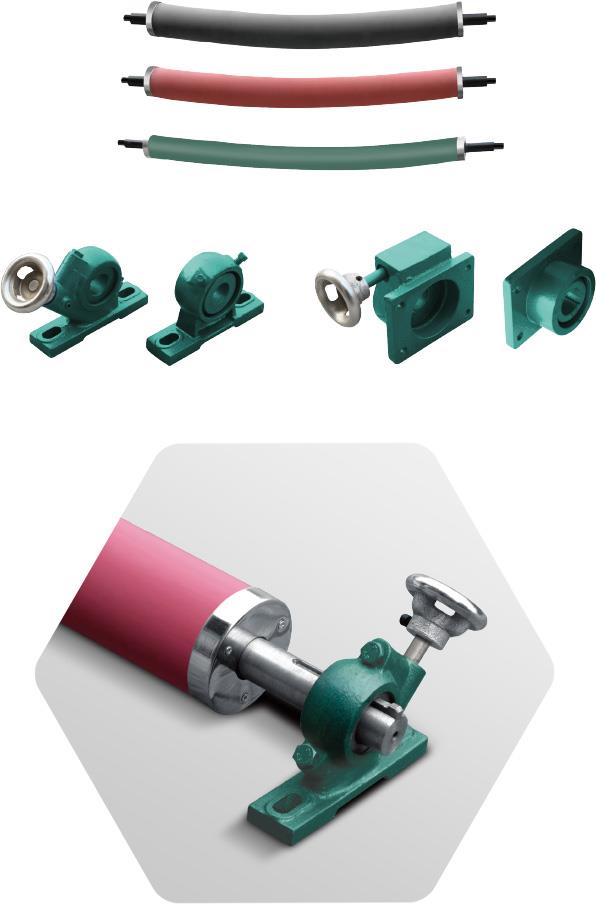

1. The material is mainly made of nitrile rubber, and the color can be red, green, black, etc.

2, the internal structure is the bearing ring

3, the inner device of the hose, the torque is small

4, the rubber surface is smooth, no adverse effect on the substrate

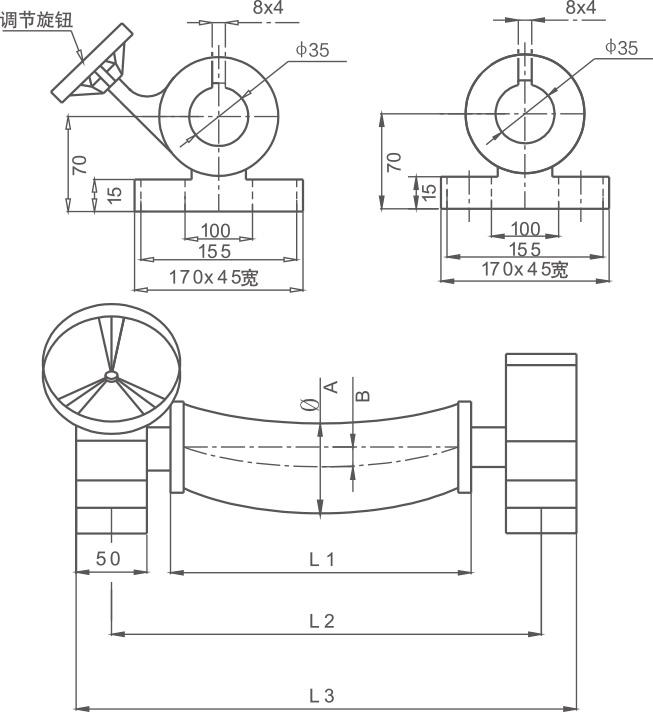

5, the stretch roller angle can be adjusted freely

6, diameter: Ф80, Ф100, Ф125, Ф150, Ф160, Ф200

In various mechanical parts, the rubber roller is often used instead of the metal roller. This rubber roller, commonly known as bakelite roller, has a high hardness of 90-100 degrees, generally functions as a conduction and support, for example, in a paper machine. The roller, the felt roller and the guide roller in the dyeing machine. If the surface of the high-hardness rubber roller is reversed to the thread, it becomes a split roller or a distribution roller, which has the effect of straightening the felt or the cloth.

Because the rubber roller has the advantages of acid and alkali resistance and no rust. It is also widely used in acid pickling in industries such as printing and dyeing, strip steel and copper. In the belt conveyors of metallurgy, mines, docks, yards and other large equipments, the active rollers for transmission have used flat roller in the past. In order to improve the friction coefficient and prevent the tape from slipping, the roller surface has been improved at home and abroad this year. Glyph or diamond.

The silicone rubber roller made of high temperature resistance and non-thermal viscosity of silicone rubber is an indispensable component in the emerging industrial sectors such as plastic woven cloth and paper fabric resin.

Application

Packaging

Order Details

Item Name | Bending Roller/Curved roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: precision resolution infeed roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy