Printing Machine Roller

Printing Roller A. Flexo printing machine(unit type ,central cylinder type,cascade type) B. Offset printing machine C. Corrugated water-based ink printing slotting machine D. Coating and lamination machine E. Glazing machine ect. Printing rubber roller maintenance In the offset printing...

Printing Roller

A. Flexo printing machine(unit type ,central cylinder type,cascade type)

B. Offset printing machine

C. Corrugated water-based ink printing slotting machine

D. Coating and lamination machine

E. Glazing machine ect.

Printing rubber roller maintenance

In the offset printing technology, the key is the control of the balance between the water path and the ink path, and the balance of the ink and ink depends on the key components of the rubber roller and the ink roller, and the quality of the ink can directly affect the product quality. This is especially true for gravure, embossing, and flexo printing. General printing companies maintain equipment once a week, including the maintenance of printing rollers. There are several ways to maintain:

1. After the daily production operation is completed, the rubber roller should be carefully cleaned and washed twice;

2. Cleaning of the printing roller must use the specified chemical, such as industrial alcohol, and must not use corrosive solvents;

3. Remove the rubber roller during holiday break to prevent deformation under pressure;

4. The protection of the surface of the printing roller should be wrapped in newsprint and placed in a dark and ventilated place.

Printing rubber roller repair

In the work process, the printing rubber roller usually appears, wears, holes, etc. If the new roller is replaced, the cost is too high and the production progress is affected. It can be repaired with a rubber repair agent.

Repair process, taking rubber repair agent as an example:

1. Surface treatment: Touch the hair to be repaired, clean, decontaminate, degrease, and dry.

2. With rubber repair, pour the rubber repair agent curing agent group B into the iron of the main agent group A and mix it quickly (A: B = 1:1), then pour it into the area to be repaired.

3. Curing: It can be used for 4-6 hours at room temperature and reaches maximum strength in 48 hours.

Application

Packing

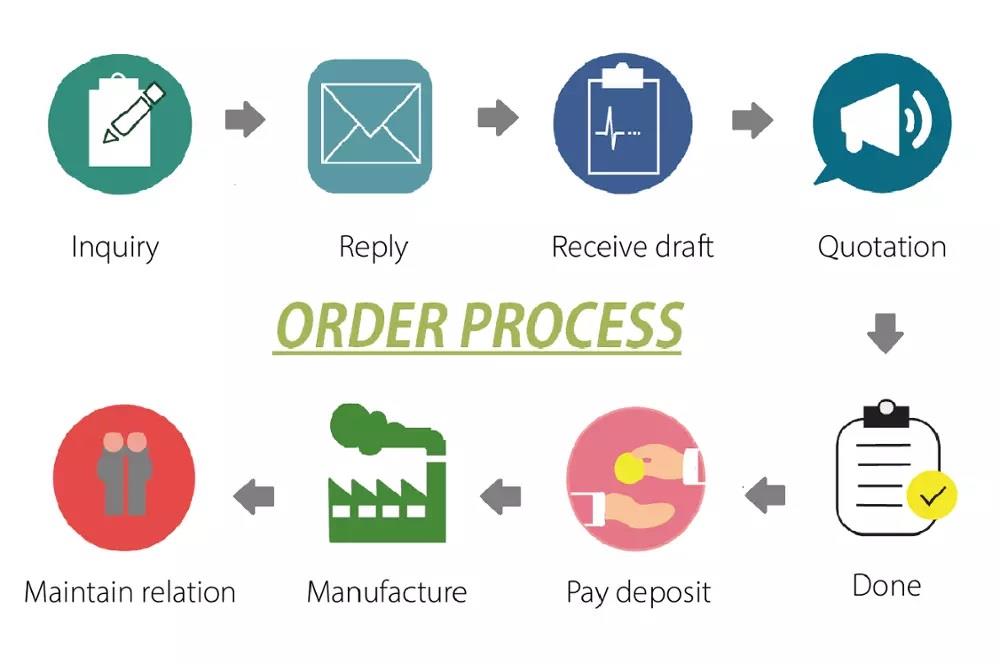

Order Details

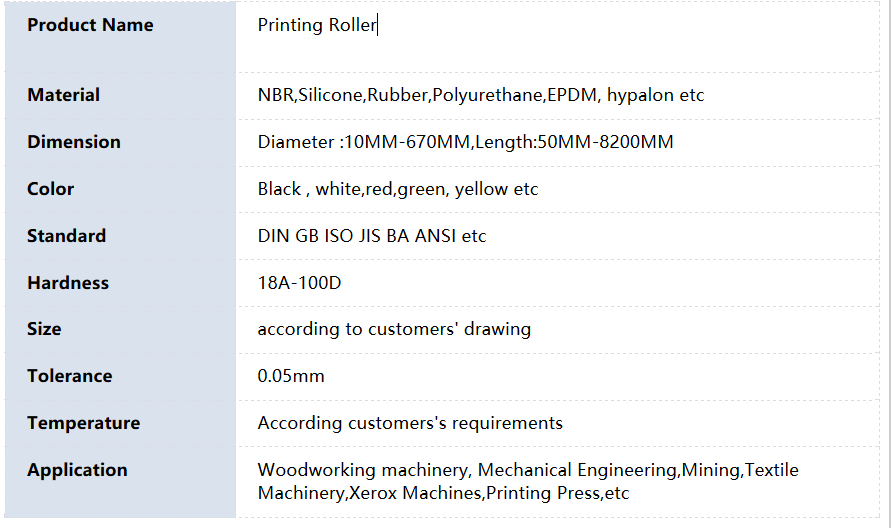

Item Name | Printing machine roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: printing machine roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy