Rubber Roll

Rubber roller basics The ink roller on the press is mainly used to transfer ink. In order to distribute the ink rapidly and evenly between the ink rollers, the printing machine is usually arranged in an alternating manner between a soft ink roller and a hard ink roller to make good contact...

Rubber roller basics

The ink roller on the press is mainly used to transfer ink. In order to distribute the ink rapidly and evenly between the ink rollers, the printing machine is usually arranged in an alternating manner between a soft ink roller and a hard ink roller to make good contact between adjacent ink rollers. Soft ink rollers (commonly known as rubber rollers) are generally made of high-grade polymers such as vulcanized natural rubber, synthetic rubber, gelatin, and polyurethane; rigid ink rollers (commonly referred to as metal rollers), generally iron Made of copper or other metal materials. The rubber roller and the metal roller themselves have good lipophilicity, so that the ink is well wetted and adhered on the surface, which is a prerequisite for ensuring the transfer of ink between the ink rollers.

Manufacturing process of rubber roller Main raw materials: high molecular polymer, vulcanizing agent, plasticizer, filler, accelerator Main process and function: mixing - filtration - curing treatment - grinding - polishing

1. Mixing: Control the content of each component, the heat drying temperature, etc., to stabilize the hardness and composition.

2. Filtration: Make the colloid even and free of impurities. This is especially important for high-speed printing presses: Uniform force is applied during high-speed operation, and evenly transmitted energy can be kept uniform even when it is expanded or contracted due to various factors, so that only relying on adjustment can reduce or avoid adverse effects.

3. Curing: By warming and pressing and vulcanization treatment, the speed-increasing agent is stabilized, so that the rubber shrinks to a minimum when subjected to external force. The soft and ductile compound is made into a solid material with a certain degree of softness, which is more suitable for ink transfer and transfer.

4. Grinding and polishing: The key to determining the dimensional accuracy and surface area of the rubber roller, especially the arc treatment of the alcohol water roller. The rubber surface looks smooth, but under a high magnification magnifier, there are many small bumps and depressions. These raised and recessed portions increase the surface area of the rubber roller, making it superior in ink transfer and transfer properties. This process requires a constant temperature: when the temperature is too high, the surface is easily charred, and peeling occurs when printing is short-time. The temperature is too low, and the part is easily embrittled, resulting in a decrease in ink transfer performance.

Rubber roller performance requirements

1. Inclusiveness - affinity for water and ink

2. Elasticity - whether the pressure can be correctly expressed; the elasticity is good and the pressure is obvious.

3. Indentation reflection - the basis for correct adjustment of printing pressure

4. Vibration absorption - prevent up and down jump, resonance (at high speed)

5. Abrasion resistance - maintains high surface area, anti-glaze ability, and maintains inclusiveness

6. Energy transfer performance - ensure that it does not accumulate energy, does not reflect energy

7. Corrosion resistance - good chemical resistance, helping to extend life

8. Conductivity - antistatic, non-adsorbing ink and paper hair

9. Heat transfer - extend your life and reduce the time to adjust the pressure

10. High temperature resistance - prolong the life of the rubber roller (especially for high speed machines)

Rubber roller hardness Rubber roller hardness is an important performance of rubber roller performance, as follows:

1.soft - inclusive, strong elasticity, strong pressure resistance, good vibration absorption, good indentation, large adjustment range of pressure

2. Has a certain hardness - not easy to be corroded and worn, strong resistance to high temperature, rapid pressure performance, so the hardness of the rubber roller needs to be moderate: too soft, poor corrosion resistance, easy to gather energy; too hard, the ability of ink transfer is reduced, the vibration absorption is poor, Easy to gradually destroy the precision design of the printing press;

Therefore, it is necessary to select the correct gel type and hardness according to the appropriate printing pressure and other printing suitability. Attachment: Indentation performance of the rubber roller (indentation width - rubber roller pressure) Increase the indentation width by 50% relative to the roller pressure required to increase by 250%. Increase the indentation width by 100%. It is necessary to increase the roller pressure by 750%.

Packing

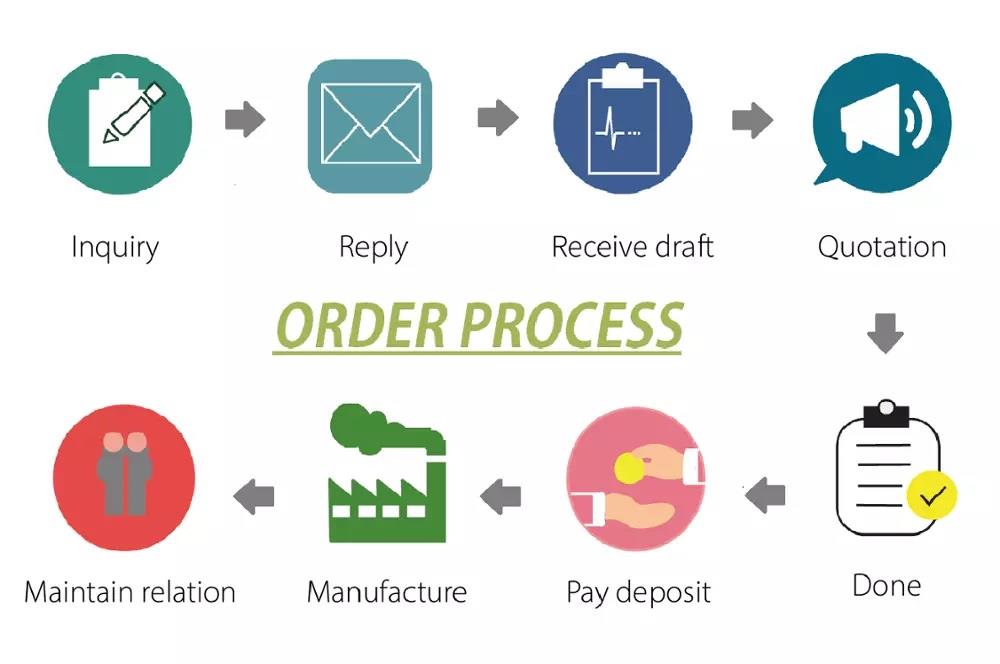

Order Details

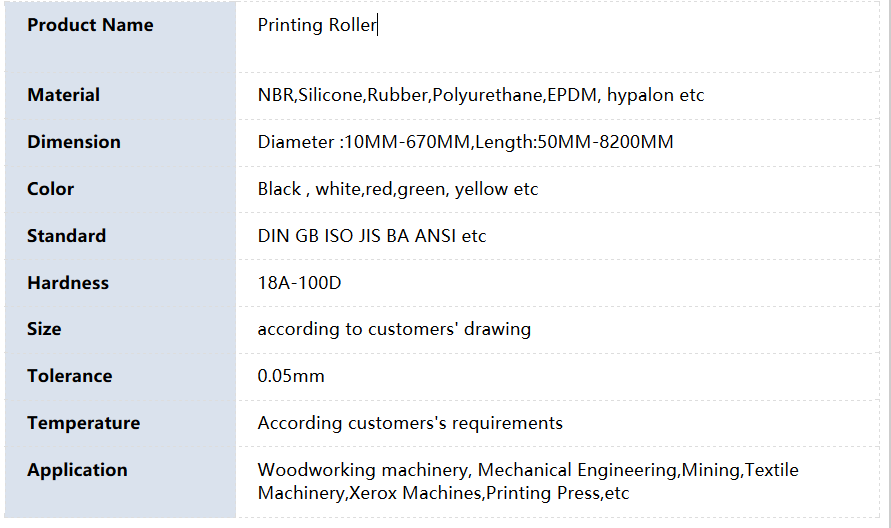

Item Name | Printing machine roller/Rubber roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: rubber roll, China, manufacturers, suppliers, factory, quotation, pricelist, buy