Sliding Shaft

Slip-type air-expansion shaft, as the main component of the slitter, to complete the slitting of various materials, if during the winding process When the material thickness is uneven and the machine tension control is unstable, the material roll will be affected and the unwinding phenomenon and...

Slip-type air-expansion shaft, as the main component of the slitter, to complete the slitting of various materials, if during the winding process

When the material thickness is uneven and the machine tension control is unstable, the material roll will be affected and the unwinding phenomenon and the whole coil will be affected.

The material is inconsistent and the material is damaged. The sliding air shaft is mainly composed of the air expansion shaft, and the center air pressure is used to control the slip.

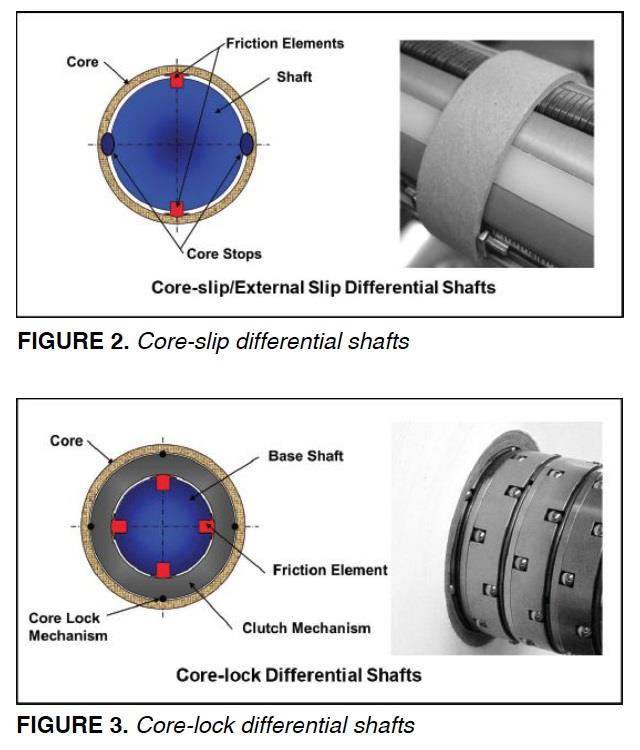

The three pistons inside the differential sleeve are pushed out, which in turn pushes each torque unit to expand outward, and according to the inflation pressure

To set the slip torque value of each torque unit, to facilitate the control of the tension adjustment of each roll of material on the split line,

It can solve the problem of unwinding caused by uneven thickness and uneven tension after striping, or material damage caused by inconsistent elasticity. It can be applied to slitting machine. The winding machine rewinding machine uses slit shaft to cut metal foil and plastic film. Paper, electronic materials and

Various composite materials, self-adhesive materials, etc.

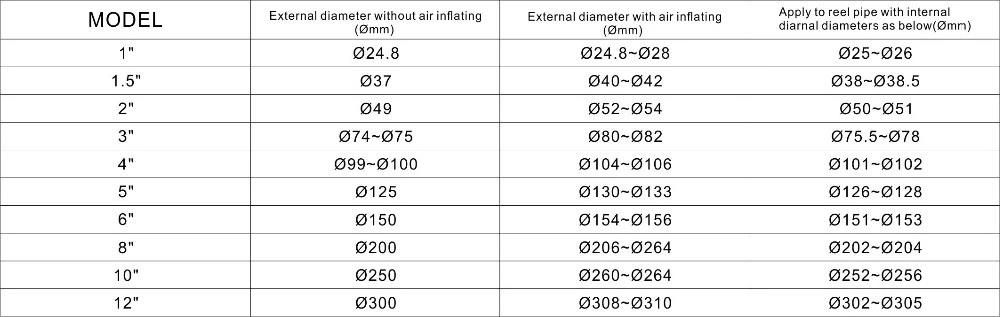

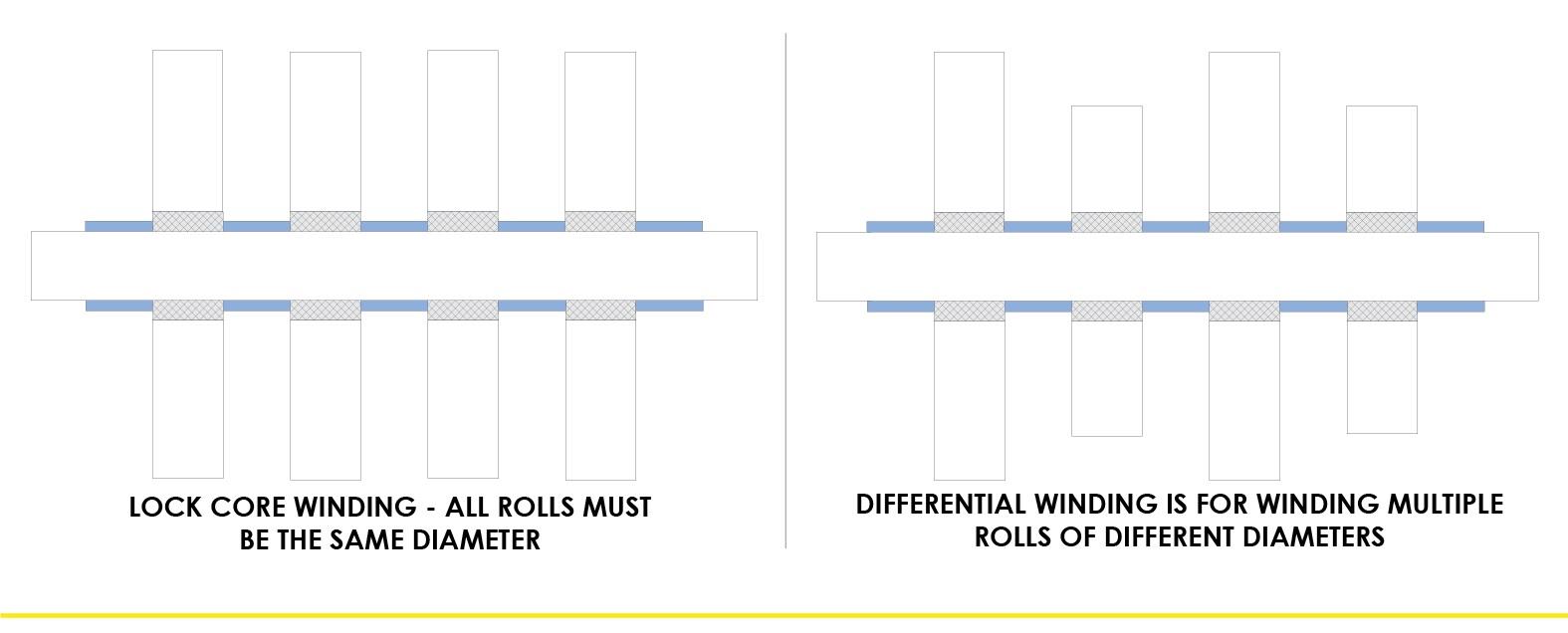

The slip type air-up shaft is mainly used for winding reels, and it is also used for reeling in special occasions. The product body is made of chrome-plated steel or hard alumina, and the friction strip can be made of polyurethane, polyethylene or rubber material, depending on the maximum tension requirements. In order to meet the special requirements of users, steel journals of different sizes can be made according to the requirements of the user's drawings. When the plastic film or other material is unwound, the thickness of the material may vary. This difference can result in significant differences in the outer diameter of the rolls during the continuous winding process, in which case the required winding torque will be slightly different.

Then, after several revolving rotations, some of the rolls may become very tight, while other rolls will begin to relax, eventually degrading the quality of the product. The Turing slip-type air-up shaft guarantees the highest roll quality, and the material will not cause problems by maintaining the proper tension of all rolls while the reel is running. The principle of operation is that the slip ring continues to slide in the center of the inflation shaft. To ensure consistent tension, some collars slide faster than other collars. Thereby, the tension of each roll of material is precisely controlled, and the constant tension is taken up to ensure the quality of the roll.

Working principle: When the air is injected into the internal expansion, the parts in the shaft body are expanded and extruded, and transformed into the shaft body.

The increase in diameter causes the coiled tub to be fully and accurately fixed to the shaft body. When the internal air is released, the expansion is zero.

When the piece is retracted, the shaft can be easily taken out.

Functional characteristics: The main body of the shaft is made of high-stress steel or aluminum alloy, and the inner expansion body is made of special imported synthetic rubber. And there are a variety of structural forms: shaft type road moving key type air expansion shaft, center road moving slat type air expansion shaft, independent adjustment slip type air expansion shaft.

Packing

Question:

Can you customized the rolls for me if I provide the size or drawing?

Answer:

Yes! All the rolls and shafts are customized for every customer.

Question:

I need the roll which diameter not included in your list, can you produce?

Answer:

Yes! We can produce all sizes of rolls.

Question:

What is the minimum order of the rolls?

Answer:

The minimum order is only 1 piece.

Question:

What is the delivery time of the roll?

Answer:

According to the quantity you order, mostly is within 30 working days.

Order Details

Item Name | sliding shaft |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 15-18 days after receiving the deposit |

Calculated Weight | Depend on dimension |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: sliding shaft, China, manufacturers, suppliers, factory, quotation, pricelist, buy