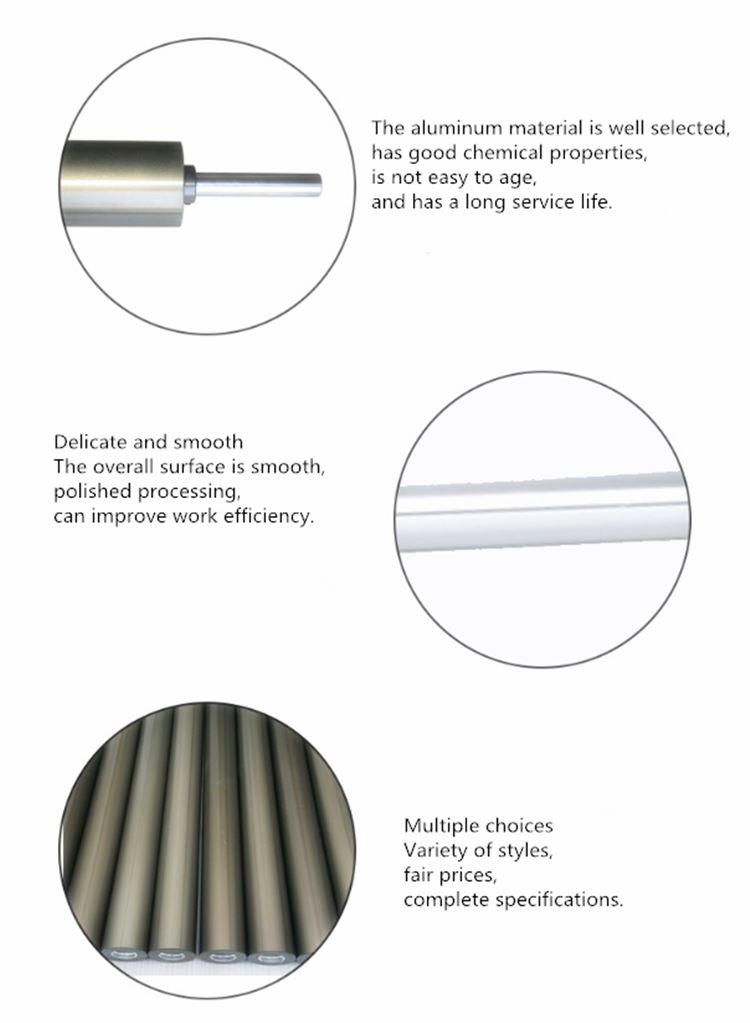

Teflon Aluminum Tube

(1) Universal white oxidized surface: moderate surface hardness HV300, low cost, can also provide different color surface (such as pure black) according to customer requirements, suitable for low tension film industry. (2) Brown hard oxidized surface: surface hardness of aluminum guide roller...

(1) Universal white oxidized surface: moderate surface hardness HV300, low cost, can also provide different color surface (such as pure black) according to customer requirements, suitable for low tension film industry.

(2) Brown hard oxidized surface: surface hardness of aluminum guide roller HV700 and oxide film thickness of 0.1mm or more. The oxidation technology introduced in Taiwan, high hardness and high abrasion resistance can be applied to various high tension and thick materials. The life of the aluminum guide roller can be greatly improved.

(C) Teflon surface: The special Teflon coating makes the ink easy to clean and provides moderate anti-stick properties.

(4) Rubber surface: The aluminum guide roller is used as the core shaft, and different rubberized layers can provide versatility of different characteristics and different hardnesses.

(5) Industrial hard chrome surface: the highest surface hardness and corrosion resistance, surface roughness can be as low as Ra0.01 (ultra-mirror surface), compared with traditional chrome-plated steel roller, light-weight chrome-plated aluminum roller can be applied to higher speed machine.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

The quality of the products is not uniform, how to create high-quality rollers? It is necessary to strictly implement the manufacturing process. If any of the intermediate processes are lacking, serious quality problems will be exposed during the actual use, which will affect the normal production of the manufacturer.

This requires the roller manufacturer to pay attention to the following points:

First, we must first strictly select the roll blank material. We should choose seamless steel pipe or forging or centrifugal casting according to different plastic products. In the process of production, we should adopt corresponding heat treatment such as quenching and tempering for different roll blanks. Process.

Secondly, in the process of processing, stress must be removed after the welding process, and surface hardening or nitriding treatment should be carried out to improve the surface hardness. These processes must not be taken out because of the high cost, which seems to be on the surface. Can not come out, but there are serious hidden dangers in the actual use of the production process, which is absolutely not allowed in the roller production.

Thirdly, the plating thickness should be strictly ensured during the electroplating and surface treatment process. In the grinding process, especially in the super-fine grinding process, the process steps should be strictly followed, and the normal steps should never be ignored. To reduce the process, otherwise it is impossible to produce a qualified roller.

In fact, the oxidation of the aluminum guide roller is a normal first thought, because the surface of the aluminum guide roller will oxidize the conjunctiva after a long time of use.

In the offset printing process, bright and fast-drying resin inks are commonly used. The characteristics of quick-drying inks are that dry oil and diffusing agent are added to the ink. These desiccants will slowly penetrate into the surface of the rubber roller to make the surface oxidize and consolidate and seal, resulting in a rubber roller feel. Lipid decline affects the effect of ink absorption and ink transfer.

The way to eliminate this drawback is to sharpen the conjunctiva layer manually or mechanically.

However, it should be noted that the diameter of the aluminum guide roller cannot be changed too much, otherwise it will affect the ink transfer performance of the inking system.

Application

Shipping

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients' demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: teflon aluminum tube, China, manufacturers, suppliers, factory, quotation, pricelist, buy