Aluminum Guide Roller

The high-strength special-section and ribs inside can signiflcantly enhance the rigidity of the aluminum tube,the excellent shrink fitted assembly procedure and the surface tooling by anodic oxidation treatment, we have two types of this product: HV300 (white) or HV700 (twenty), or Special...

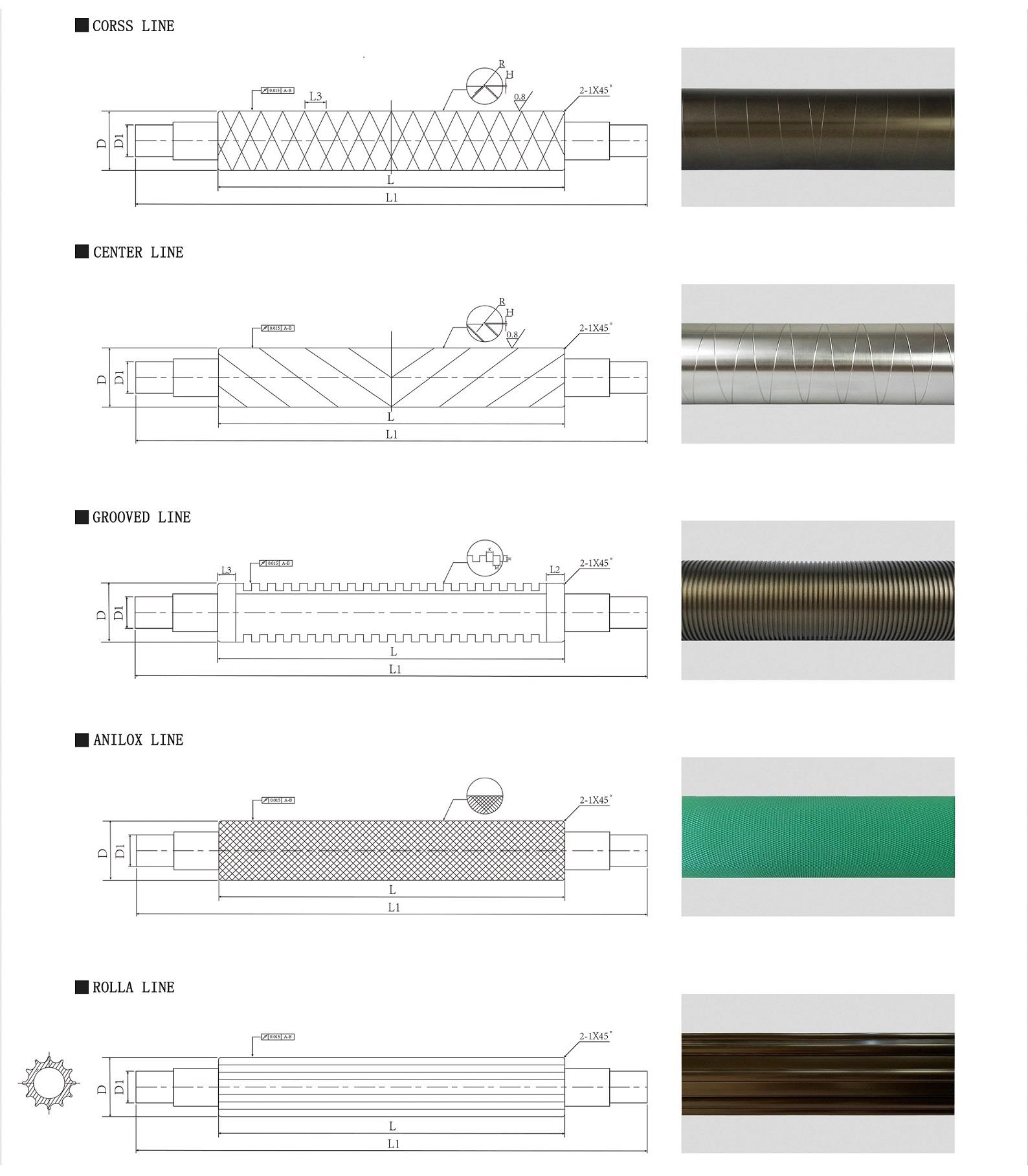

The high-strength special-section and ribs inside can signiflcantly enhance the rigidity of the aluminum tube,the excellent shrink fitted assembly procedure and the surface tooling by anodic oxidation treatment, we have two types of this product: HV300 (white) or HV700 (twenty), or Special material processing,roll body smooth finish is 0.8, dynamic balance is G2.5; Aluminum tube generally have 8-10 reinforcement. We can make slot roller according to customers' requirement, such as: Crossover aluminum roller, horizontal center, aluminum roller, roller, and cooling roller.

What are the maintenance procedures for aluminum guide rollers? Here are a series of steps to be taken when the aluminum guide roller is being serviced:

Aluminum guide roller deglaze maintenance: remove the glass layer on the outer surface of the rubber roller to maintain the superior appearance roughness.

Aluminum guide roller decalcification: In the printing process, the rubber roller is often erupted, and the ink-receiving function is reduced, which causes the ink roller to be launched and the water roller to be inked. The effect is easily erupted when printing the field war network. It is caused by the calcification of the rubber roller. Calcium comes from paper and water in printing. Every day, calcium is precipitated on the ink roller and water roller from time to time. Therefore, calcium removal is a must in the printing. .

Aluminum guide roller color change clean and maintenance: When printing dark color to light color and spot color printing color change, it often happens to be clean and hard, long color change time, thus reducing the effectiveness of the printing press, forming a waste rate increase; and clean It does not completely accumulate in the rubber surface, increasing the surface roughness of the rubber roller. Therefore, we emphasize that the maintenance starts from every day, and every time it is clean, it must be clean and completely clean. The idle rotation of the aluminum guide roller: In order to prevent the influence of the temperature on the rubber roller and maintain the superior shape of the rubber of the idler seat, the demand for the ink roller of the empty car is specially taken care of.

Dead ink hardening: The hard roller in printing easily produces dry ink accumulation under the condition of frequent color change, and each time the clean ink roller is clean, the hard roller is clean and there is no soft roller, so the demand is clean and hard roller The ink on the death is to prevent the effect on the life of the soft roller and the effect on color recovery due to the consequences of the hard roller.

The recovery of the current colloidal rubber: After the rubber roller is applied for a period of time, the demand is restored to the hardness and elasticity of the rubber, and the ink accumulated on the rubber roller, paper powder and paper wool are completely cleaned. The rubber roller after recovery can be used. There is a printing performance of the new rubber roller.

Appication

Order Details

Item Name | Aluminum guide roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients’demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum guide roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy