Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Overview:

Magnetic powder clutch and magnetic powder brake use magnetic powder under electromagnetic effect to transmit torque. It has the advantages of linear relationship between excitation current and transmission torque, fast response, simple structure, no impact, no vibration, no noise, no pollution. It is a multi-purpose automatic control component with excellent performance. It is widely used in the loading and braking of machinery in various industries and the tension control of winding and unwinding in the winding system.

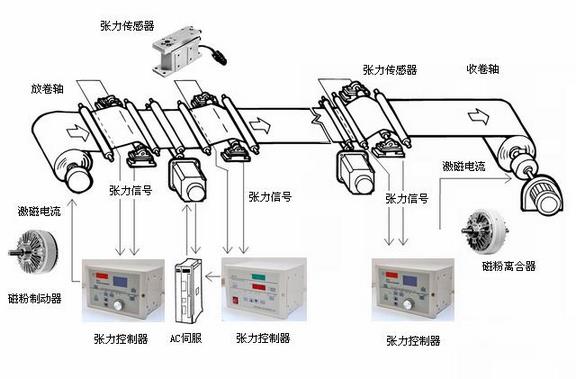

General application diagram 1 (for tension control):

Unwinding:

The tension of the unwinding is controlled by the braking torque of the magnetic powder brake in the unwinding device, and the braking torque must be continuously reduced as the winding diameter of the winding is continuously decreased. In the figure, the tension detector is used to detect the winding. The tension of the object is automatically controlled by the tension controller to control the torque of the magnetic powder brake to make the tension constant.

Winding:

The winding speed is normally faster than the line speed of the material, so the magnetic powder clutch works in the slip state, and the tension is controlled by the torque of the magnetic powder clutch. In order to keep the tension constant, the magnetic powder clutch must be increased or decreased according to the size of the winding diameter. Torque.

Application range:

Paper industry, production of adhesive tape, wire and cable manufacturing, packaging industry

Paper processing printing industry film, film industry textile industry

Metal foil processing Rubber industry Fiber industry Gasoline engine, diesel engine loading and running, testing Loading in various tests Leather industry Fiber manufacturing Other related coiling processing industry

Features:

The excitation current is linear with the torque:

The torque of the magnetic powder brake is basically linear with the magnitude of the exciting current. The magnitude of the control torque can be arbitrarily adjusted by changing the magnitude of the exciting current.

Stable speed---torque characteristics

When the excitation current remains the same, the torque will be transmitted steadily without being affected by the change in speed. This feature is used in tension control, and only needs to adjust the excitation current to accurately control the torque, so as to achieve the purpose of controlling the tension.

Effective heat sink and its load characteristics:

Continuous sliding friction can not avoid heat, magnetic powder clutch and magnetic powder brake have complete heat dissipation device, wherein stator water cooling and stator rotor double water cooling products can meet the needs of high power slip.

When the heat dissipation condition of the product is constant, the maximum slip power allowed by the product is a fixed value, and the torque and the rotational speed can compensate each other within a certain range. Of course, neither torque nor speed can exceed its maximum value.

Example: FZJ-10 magnetic powder brake:

Its slip power p=8KW, when its torque M=100Nm is used:

n=9550*p(kw)/M(Nm)=780rpm

That is, when the torque is 100Nm, the rotation speed cannot exceed 780rpm.

If the speed is continuously running at n=1500rpm, the allowable torque is

M=9550p/n=9550*8/1500=51Nm

That is, if the speed is increased to 1500 rpm, the torque can only be used continuously at 51 Nm.

The control power is small:

Magnetic powder clutch and magnetic powder brake use magnetic powder under electromagnetic effect to transmit torque. It can control large transmission power with very small electric power. It is easy to control by electronic circuit and computer. It can be easily applied to all walks of life.

Quick response features:

Due to its inherent structural characteristics, the magnetic powder clutch and magnetic powder brake have determined that the non-response time, torque rise time and torque drop time of the product are extremely short. This characteristic determines that the magnetic powder clutch and the magnetic powder brake can be applied to frequently start and stop. , reversing applications. Special needs can be further optimized by mechanical parts and improved loading power to increase response speed. Taking the 5kgm magnetic powder brake as an example, its non-response time is 25ms, and its torque rise and fall time is 270ms and 350ms respectively.

Previous: Method And Precautions For Replacing Magnetic Powder In Magnetic Powder Clutch

Next: Magnetic Powder Clutch And Manual Tension Controller Working Principle