Web Guiding Controller

Web Guiding Controller Concept: Correction Controller, also known as edge position control (E.P.C), developed and line position (L.P.C) center line position control (C.P.C) The Principle of Guiding Controller: During the material winding process, the position of the edge or line is detected by...

Web Guiding Controller Concept:

Correction Controller, also known as edge position control (E.P.C), developed and line position (L.P.C) center line position control (C.P.C)

The Principle of Guiding Controller:

During the material winding process, the position of the edge or line is detected by the sensor to pick up the edge or line position deviation signal. Then, the position deviation signal is transmitted to the correction controller for logic operation, and a control signal is sent to the mechanical actuator to drive the mechanical actuator to correct the serpentine deviation of the material during operation to ensure linear motion of the material. Optional left and right limit switches prevent the system from running out of control.

Main Performance Indicators of Guide Controller:

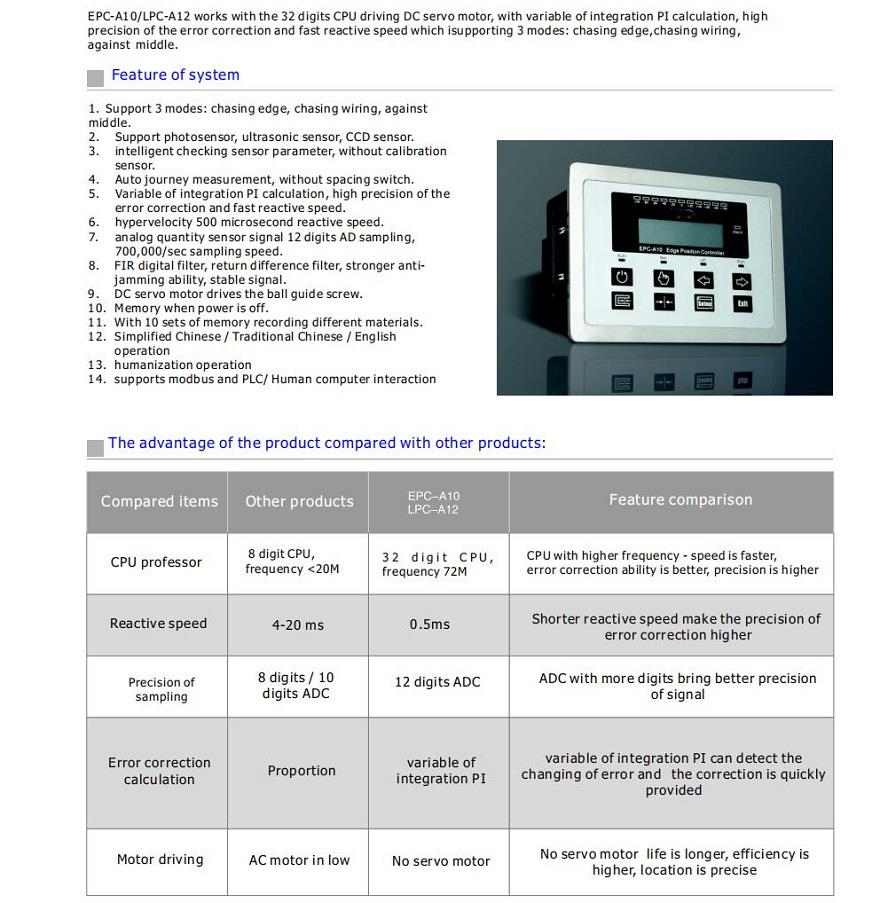

1. Support LPC Line Guide, EPC Edge Guide, and CPC Center Guide;

2.Support photoelectric sensor, ultrasonic sensor, CCD sensor;

3.Intelligent detection of sensor parameters, no need to calibrate the sensor in most environments;

4.Automatic stroke measurement, no mechanical limit switch;

5.No overshoot integral variable PI adjustment algorithm, high precision, quick response, less error;

6.Ultra-high speed 500 microseconds (0.5 milliseconds) response speed;

7.Analog sensor signal 12-bit AD sampling, 700,000 times per second sampling speed;

8.Using FIR digital filter, hysteresis filter, anti-interference ability is stronger, the signal is more stable;

9.DC servo motor pushes the ball screw;

10.All system status parameters power-down memory;

11.Storage 10 sets of different material parameters, switching materials is convenient;

12.Simplified Chinese/Traditional Chinese/English three language menu operation;

13.Humanized operation, "one-button" calibration, fast and easy;

14.Support Modbus bus and PLC/man-machine interface network control;

15.Perfect anti-interference technology can effectively eliminate the influence of static electricity, radiation and noise on the system;

16.Low power consumption, energy saving;

Features,Advantages of EPC Edge Guide EPC-A10:

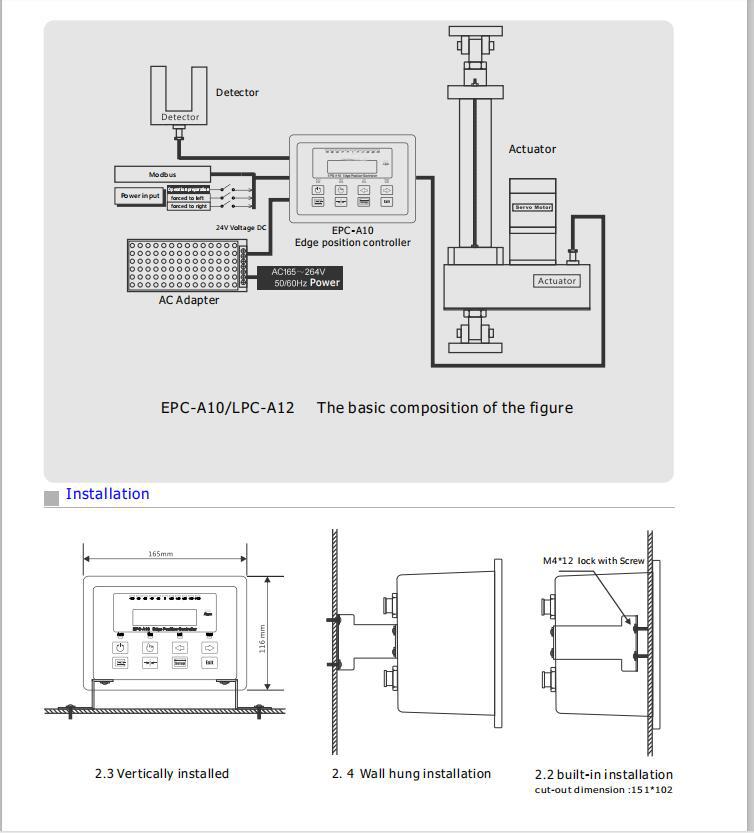

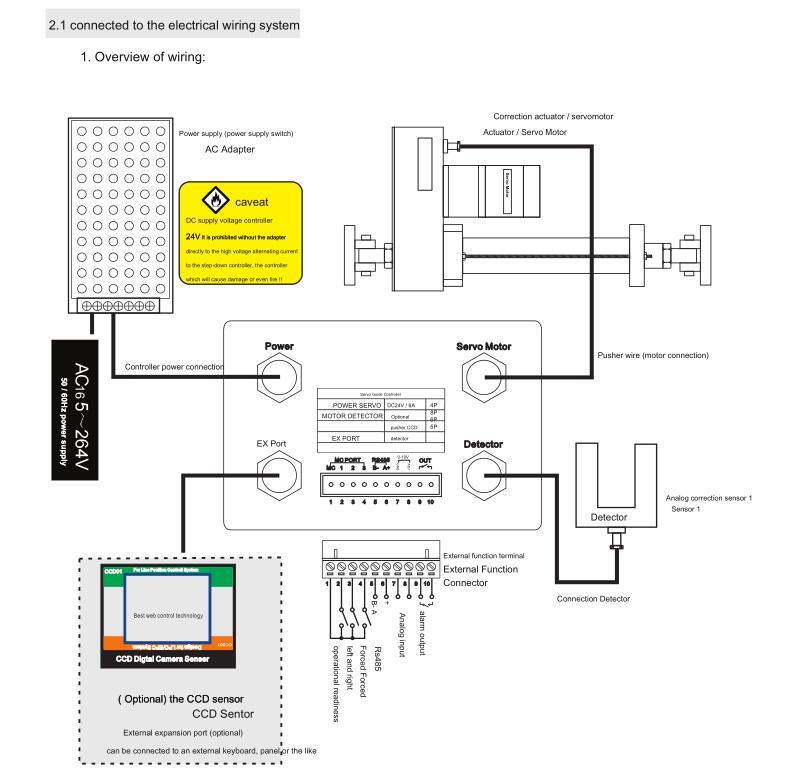

Connection,Installation of EPC Edge Guide EPC-A10:

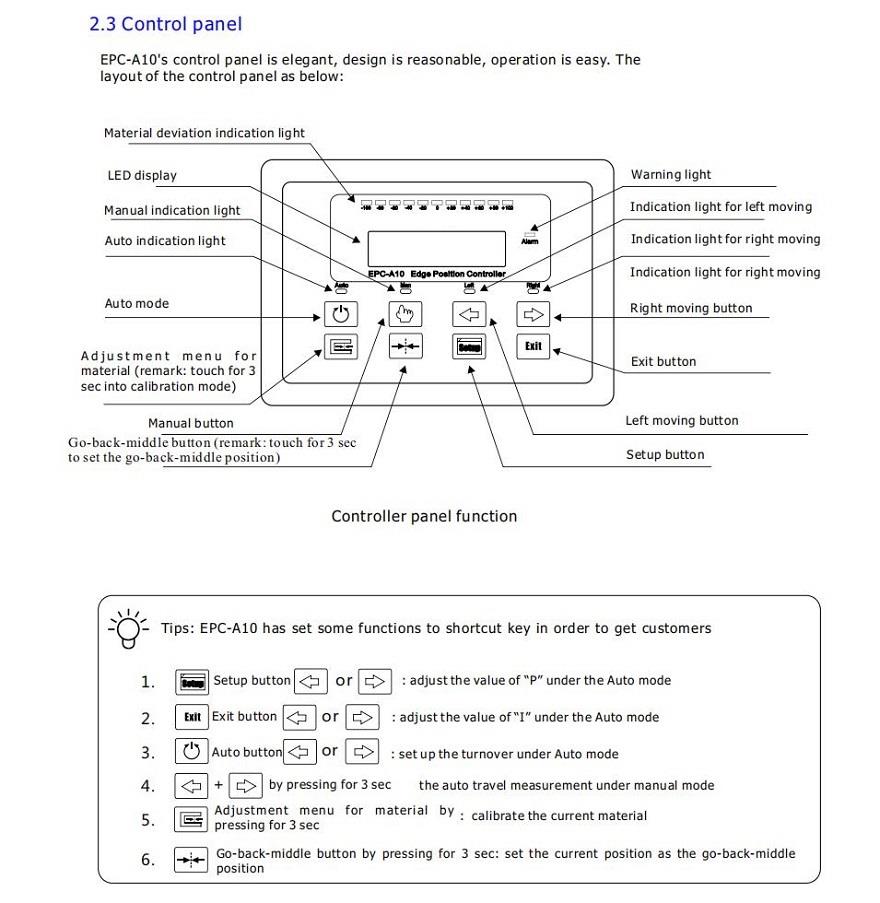

Control Panel of EPC Edge Guide EPC-A10:

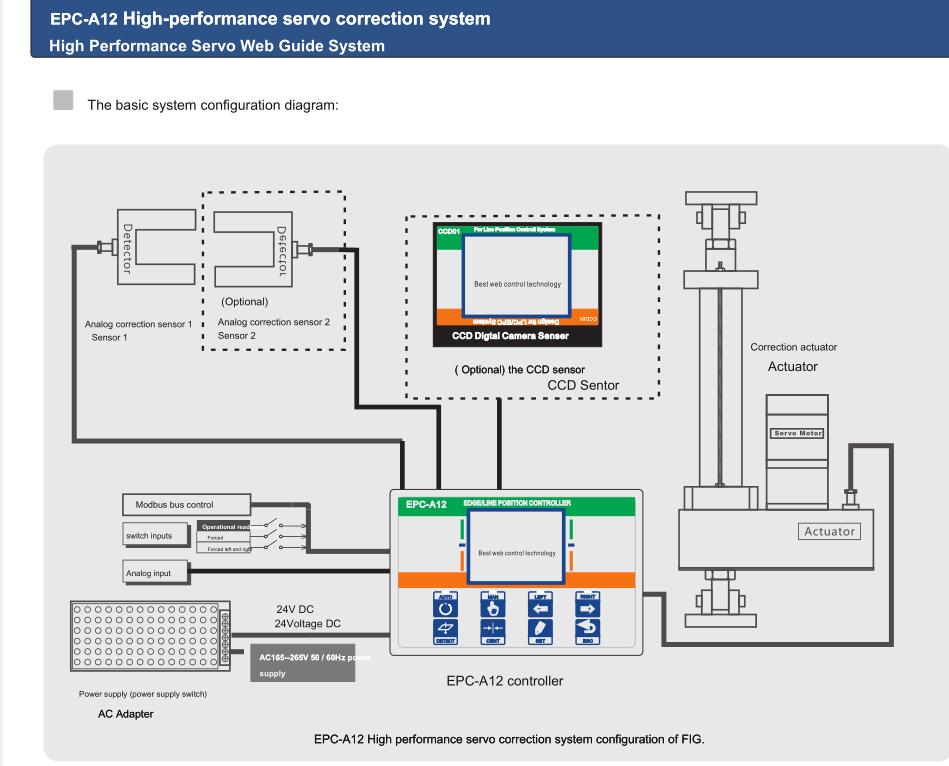

Connection of LPC Line Guide EPC/LPC-A12:

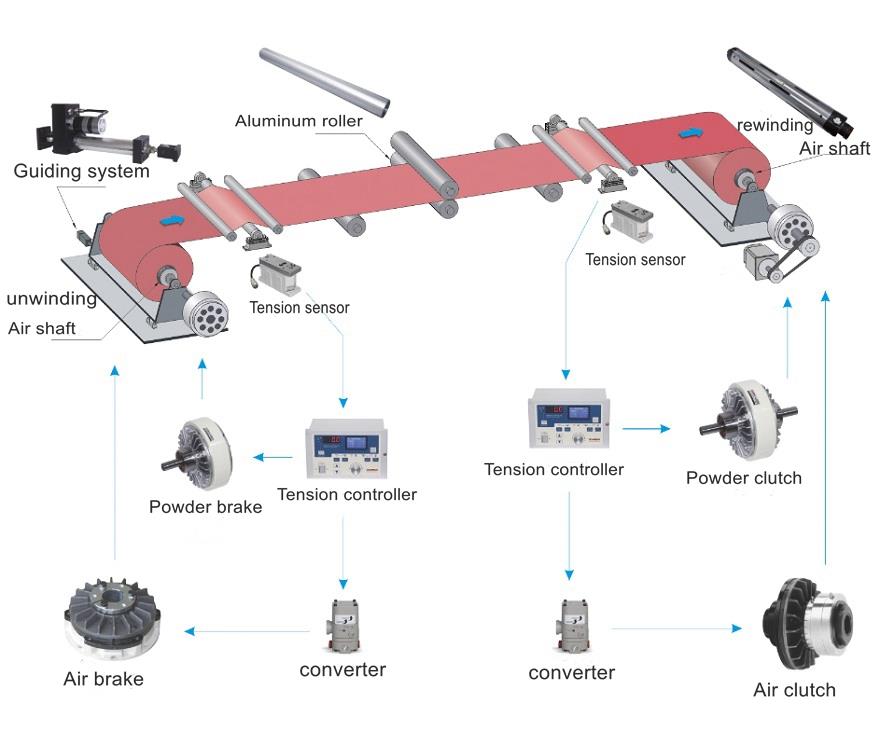

Collocation with Sensors,Actuators & Displacement Guides:

Correction Controller Features:

1. The driving torque is 1/3 compared with the sliding screw pair

2. High-precision guarantee, the ball screw is continuously produced by the world's highest level of mechanical equipment made in Japan, especially in the factory environment of grinding, assembling and inspecting various processes, the temperature and humidity are strictly controlled. Due to the perfect quality management system, the accuracy is fully guaranteed.

3. Micro-feeding is possible. Since the ball screw is made by ball movement, the starting torque is extremely small, and there is no crawling phenomenon like sliding movement, which can ensure accurate micro-feeding.

4. No backlash, high rigidity, ball screw can be added to the pressure, the axial clearance can reach a negative value due to the pre-pressure, and then get higher rigidity (by the ball screw to add pressure to the ball, in actual use In mechanical devices and the like, the rigidity of the wire mother portion can be enhanced due to the repulsive force of the balls.

5. High-speed feed is possible. Due to high movement efficiency and low heat generation, the ball screw can achieve high-speed feed (motion).

The Application of Web Guiding Controller:

The web guiding controller can correct the deviation of various coils. According to the different printing patterns of the rectifying materials, the heel and the line can be selected, and the single electric or double electric eye detection can be freely set. The rectifying and executing motor is a permanent magnet low speed synchronous motor.Mainly used in printing, packaging, paper, film, textile and other industries need to control the occasion of the curling.

Order Details

Item Name | Edge/Line/Center Guiding Controller |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 2 days after receiving the deposit |

Calculated Packing Size | 15cm*10cm*10cm |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: web guiding controller, China, manufacturers, suppliers, factory, quotation, pricelist, buy