Web Guiding System For Slitting Rewinding Machine

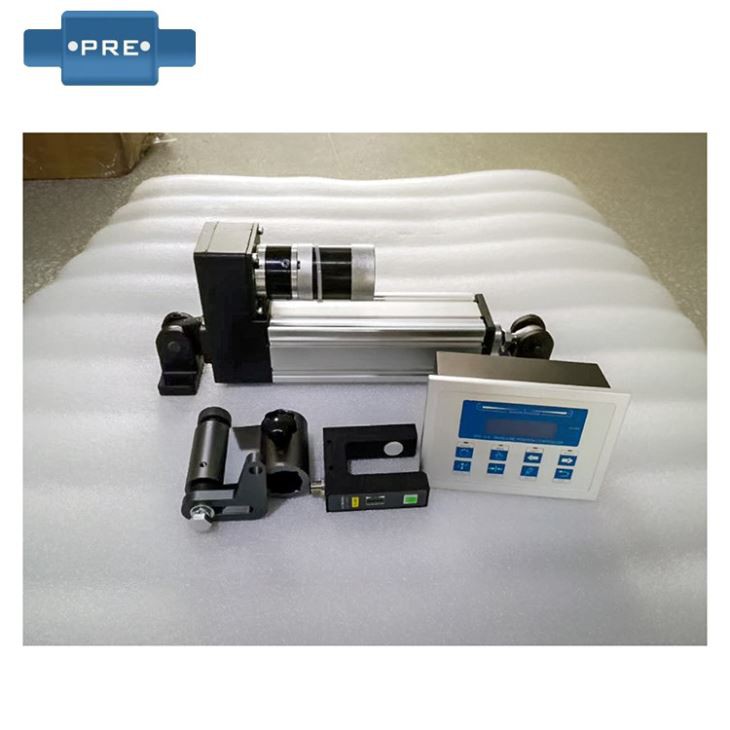

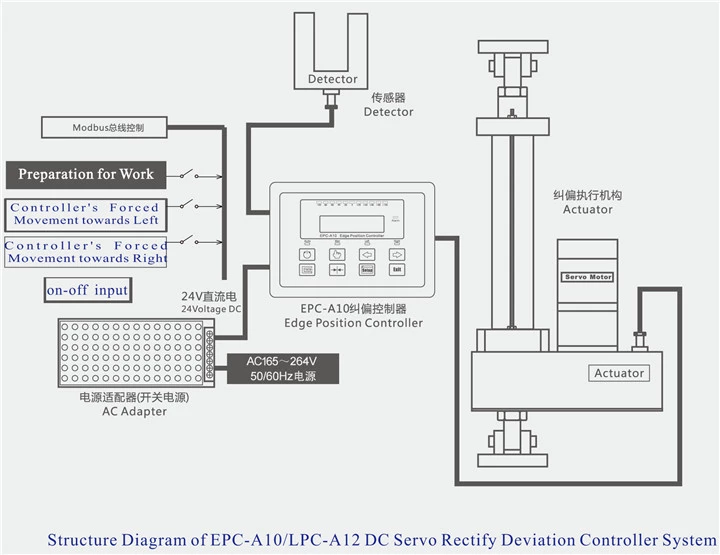

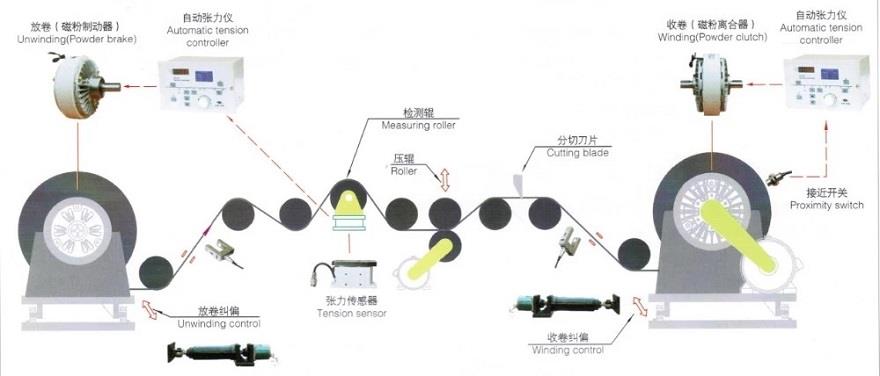

The system consists of three parts: controller, sensor and driver. During the production process, the material is detected by the sensor. When the material deviates, the sensor transmits the deviation value to the controller. The controller will instruct the driver to quickly pull the material...

The system consists of three parts: controller, sensor and driver. During the production process, the material is detected by the sensor. When the material deviates, the sensor transmits the deviation value to the controller. The controller will instruct the driver to quickly pull the material back to the travel track set by the system according to the deviation value.

Curly materials, such as paper, film, cloth, metal foil, etc., may cause the material to deviate from the correct travel path due to material deviation or equipment reasons during travel, thereby causing the printed pattern to be misaligned or wound. The function of the correction control system is to correct the material in time after the material is offset, to ensure the accuracy of the material travel route, and to reduce the defective products caused by the positional deviation of the material position in the production process.

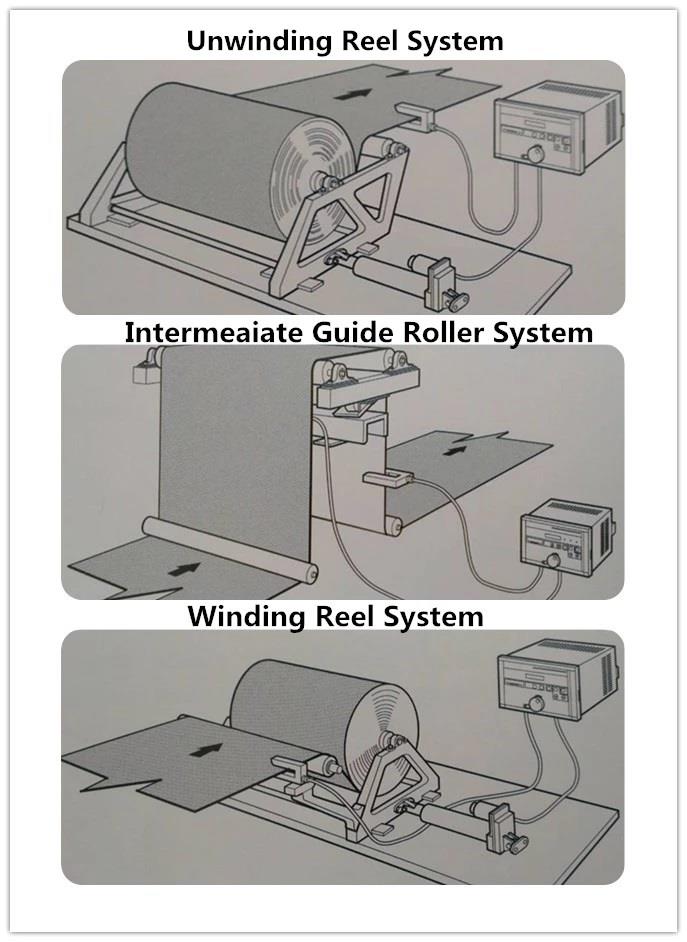

Installation :

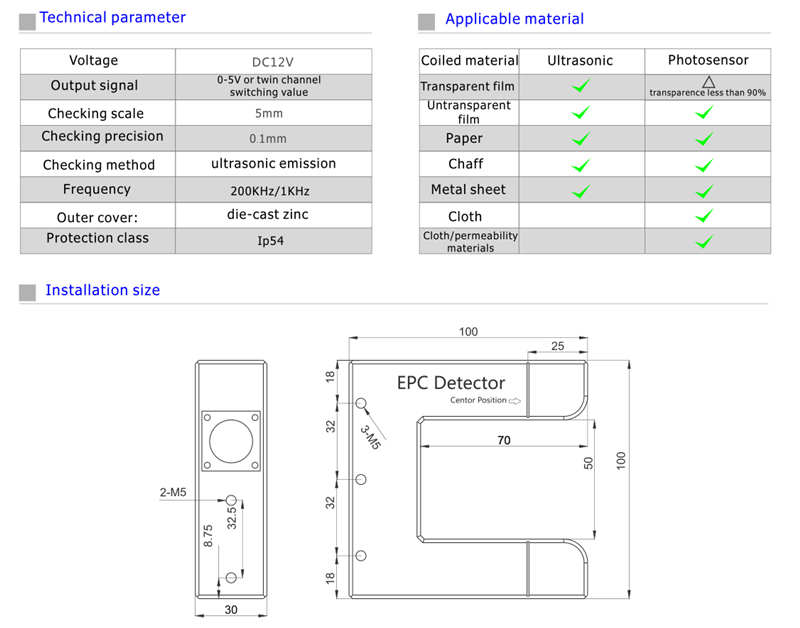

Guide sensor

In actual production, the error in the splicing of materials and materials is an inevitable actual situation.

In the production process, we often encounter the following situations:

1 material offset

The material is offset during travel due to mechanical precision, temperature and humidity, or airflow.

2 snake line materials

Periodically irregular positioning errors due to mechanical structural errors or material reasons.

3 Inaccurate receipt and discharge

Poor winding and unwinding deviation due to inaccurate winding or unwinding equipment.

When the material passes through the sensor, the sensor transmits the detected signal to the controller, and the controller compares the detected value with the preset parameter, and then issues a relevant correction signal, and the driver pushes the guiding bracket to correct the deviation.

Application

Winding guide system: ensure that the edge of the winding is neat.

Installation precautions: The sensor is integrated with the pusher to ensure that the reel is synchronized with the sensor.

Packing

Order Details

Item Name | Pivot Web Guide Systems for unwind and rewind |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Weight | Depend on model set |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: web guiding system for slitting rewinding machine, China, manufacturers, suppliers, factory, quotation, pricelist, buy