Web Guidings Machinery

The servoymmetric control system provides the corrective control you need to help your production line run efficiently and efficiently. Combined with appropriate sensors, drivers, and other guiding components, the guiding device can provide high-precision, balanced, closed-loop, high-dynamic...

The servoymmetric control system provides the corrective control you need to help your production line run efficiently and efficiently. Combined with appropriate sensors, drivers, and other guiding components, the guiding device can provide high-precision, balanced, closed-loop, high-dynamic response servo system. The guiding device is a mechanical device for guiding the side error of the coil in the forward movement. The displacement guiding is to realize the side correction of the coil by changing the span of the coil at the inlet and the outlet.

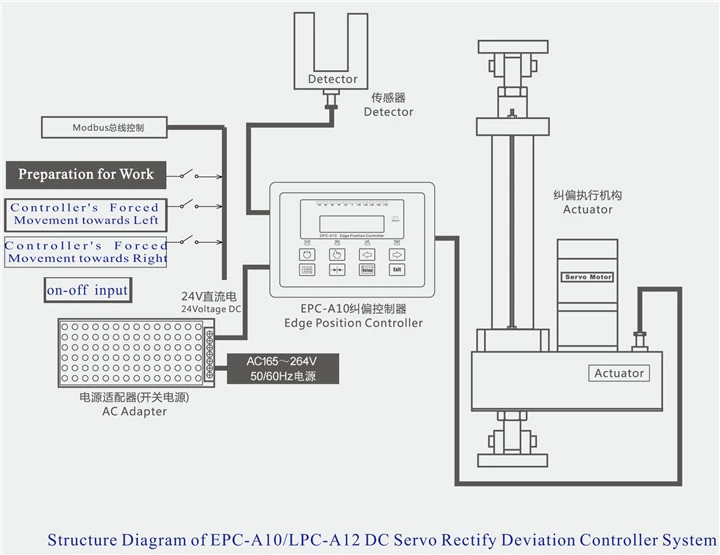

The servo guiding control system consists of three parts:

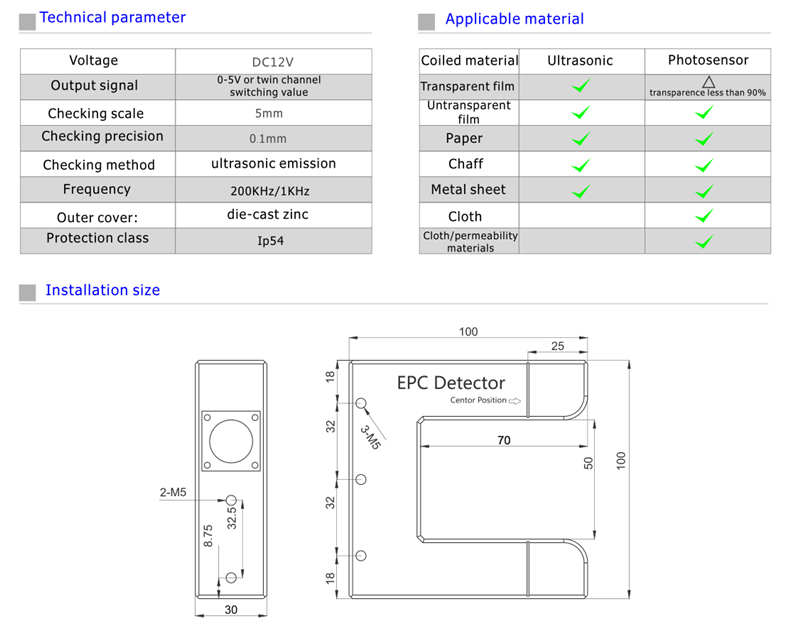

1. Sensor: The photoelectric detection switch is used to detect the deviation of the “line” mark or the “edge” mark.

2. Photoelectric guiding instrument: Perform logic operation on the sampling signal and output control signal.

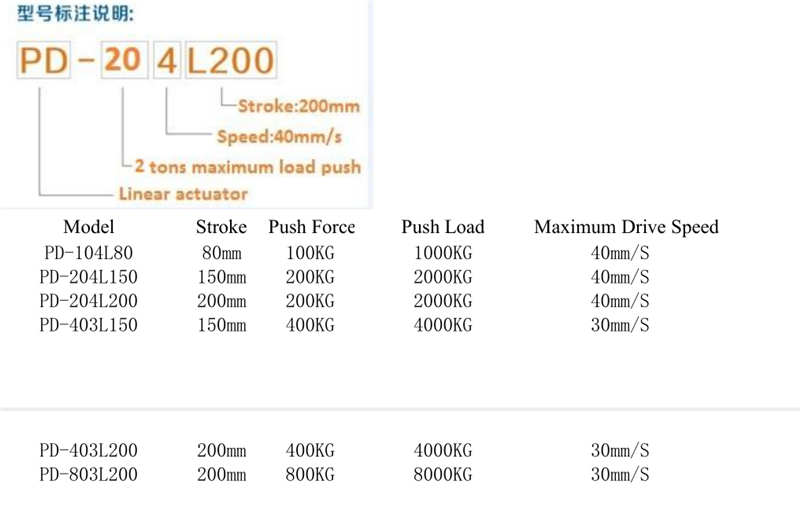

3. Mechanical actuator: It consists of AC synchronous motor, lead screw and carriage. It completes the traction of the material and corrects the deviation of the material during operation.

Servo guiding control system features:

1, can adapt to the detection of different materials, the identification of different materials, can be easily solved by calibrating the sensor.

2, a variety of combinations to reduce your investment, photoelectric guiding system has multiple series, dozens of products can be combined according to customer needs.

3, ipm intelligent drive module easily solves heavy load start, ensuring corrective accuracy. The series adopts ipm intelligent drive module, the motor starting torque is twice the rated torque, which effectively solves the heavy load.

4. Servo closed-loop control, which can independently realize actuator limit protection and center position setting, long-term trouble-free operation without adding encoder and limit switch.

5. The automatic brake function improves the guiding accuracy. The automatic brake function can improve the control accuracy due to the error caused by the inertia when the control point is reached during the avoidance of the deviation guiding operation.

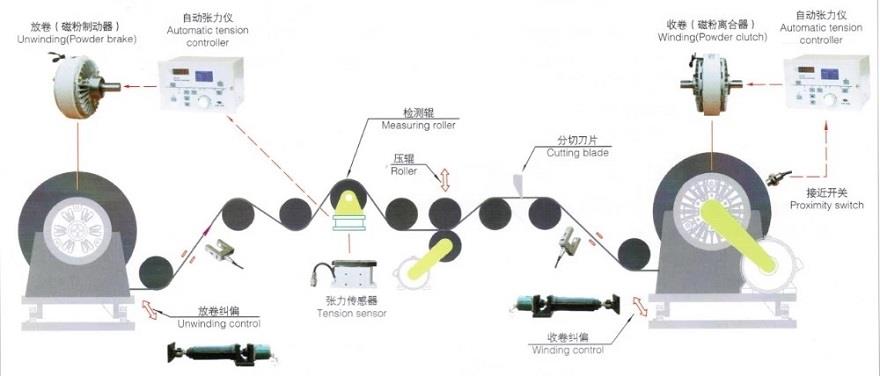

During the material winding process, the servo guiding control system detects the position of the edge or line by the photoelectric guiding driver to pick up the edge or line position deviation signal. Then, the position deviation signal is transmitted to the photoelectric guiding controller for logic operation, and a control signal is sent to the mechanical actuator to drive the mechanical actuator to correct the serpentine deviation of the material during operation to ensure linear motion of the material. Optional left and right limit switches prevent the system from running out of control. The photoelectric guiding system is a system for controlling the horizontal position shift of thin soft materials during the transmission process, and has functions of automatic detection, automatic tracking, automatic adjustment and the like.

Edge Position Control system:

Installation :

Guide sensor

Application

Packing

Order Details

Item Name |

Pivot Web Guide Systems for unwind and rewind |

|

MOQ(Minimum Order Quantity) |

1Pc |

|

Lead time |

3-5 days after receiving the deposit |

|

Calculated Weight |

Depend on model set |

|

Package |

Carton/Wooden Box |

|

Price Term |

EXW,FOB, CIF, etc |

|

Payment term |

TT,L/C,Western Union |

|

Country of Origin |

China |

Hot Tags: web guidings machinery, China, manufacturers, suppliers, factory, quotation, pricelist, buy