What Is Linearity Measurement

CCD/HCCD sensor is a color linear camera, which can track the edges of materials, contrast edees, lines, patterns and so on. Because the materials to be tracked are different, we need to tell teh sensor the target ti be tracked, which requires calibration of the target to be tracked.

CCD/HCCD sensor is a color linear camera, which can track the edges of materials, contrast edees, lines, patterns and so on. Because the materials to be tracked are different, we need to tell teh sensor the target ti be tracked, which requires calibration of the target to be tracked.

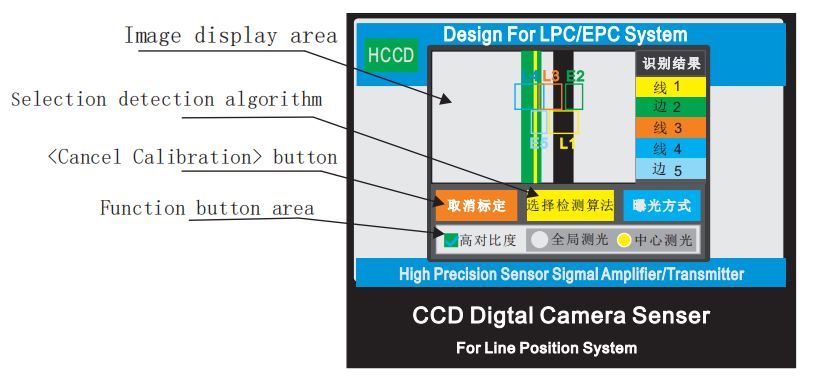

The image taken by the CCD sensor is displayed in the image display area. If the target is tracked in the image, a blue square is used to mark the target and display the offset value if the target. A yellow vertical line is the used to indicate the center position of the image display area.

Features

1. High precision

a. Accuracy: 0.02mm

b. The finest trace: 0.2mm

c. Detection range: 20mm

2. High speed

Reaction time: 2ms

3. High stability

Full metal housing, high-speed digital communication to ensure freedom from outside interference

4. Powerful performance

Can chase and chase

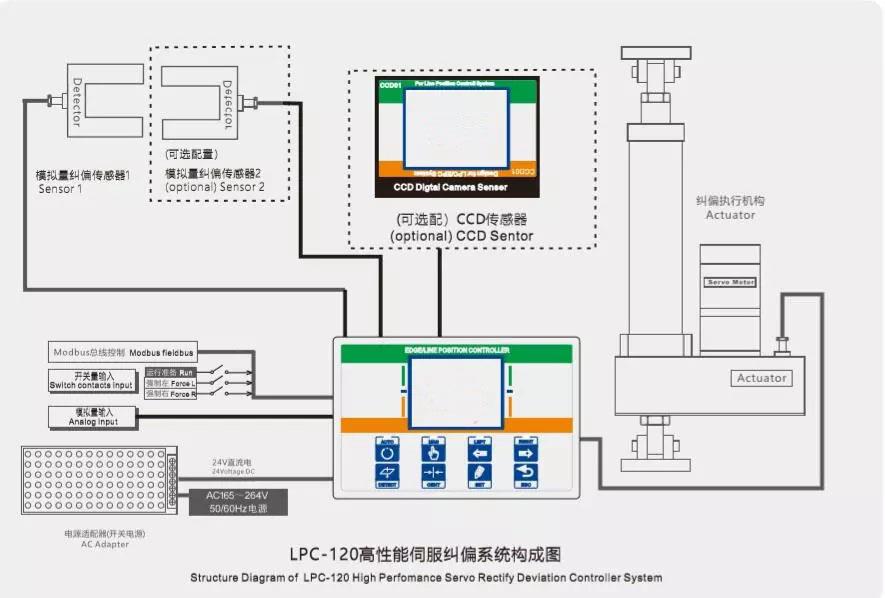

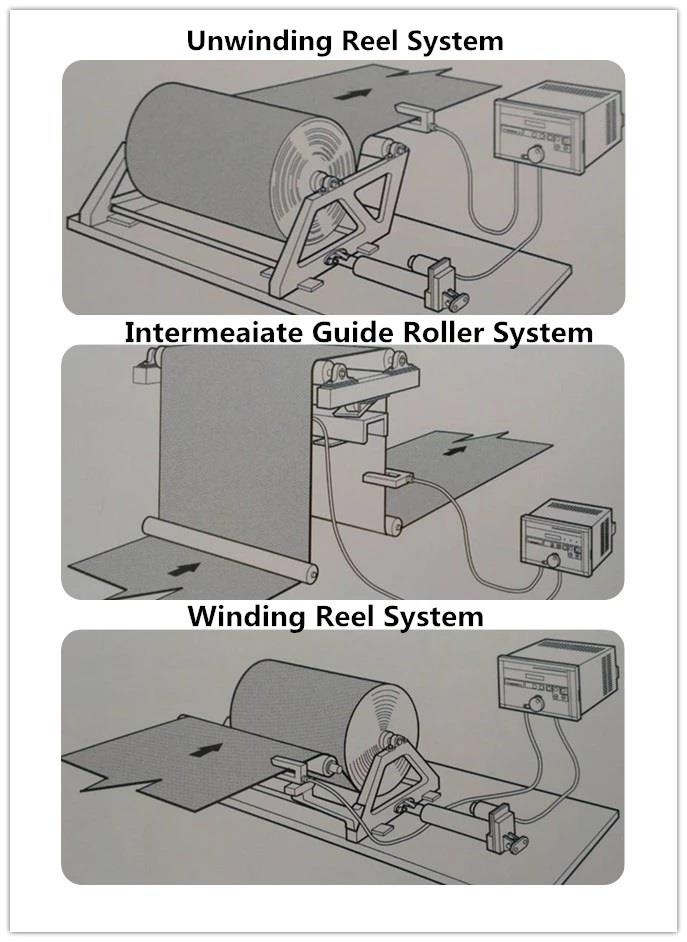

Guide system refers to the extensive use of the technical operation of the coil produced by the manufacturer during the spraying, printing, die cutting, laminating, slitting or other coil winding process, which always keeps the side of the coil neat and consistent. Bringing great benefits to the industry, correction control has led to the emergence of steel, corrugated, textile, printing, labeling, labeling, paper, plastic film, building materials, cables, rubber, tires, non-woven corrugated paper processing industries. Automated control.

In order to ensure the uninterrupted operation of the corrector, it must be maintained and maintained frequently:

(1) Neat: tools, workpieces, and accessories are placed neatly; safety protection devices are complete; line piping is complete.

(2) Cleaning: clean inside and outside; all sliding surfaces and screws, gears, racks, etc. are free of oil and no bumps; no oil leakage, no water leakage, no air leakage, no leakage; cleaning of the garbage.

(3) Lubrication: Oil is changed on time, oil quality meets the requirements; oil pot, oil gun, oil cup, linoleum, oil line are clean and complete, the oil mark is bright, and the oil path is smooth.

(4) Safety: Implement the system of fixed and fixed shifts; familiarize with the maintenance structure of the correction system and observe the operating procedures, use the corrective system to maintain, carefully maintain the tools, and prevent accidents.

Principles and requirements:

The routine maintenance of equipment is the basic work of equipment maintenance, and must be institutionalized and standardized. For the regular maintenance of equipment, work quotas and material consumption quotas shall be established, and assessment shall be carried out according to the quota. The regular maintenance work of equipment shall be included in the assessment content of the workshop contract responsibility system. Regular inspection of equipment is a planned preventive inspection. In addition to the human senses, the inspection methods must also have certain inspection tools and instruments. The inspections are carried out according to regular inspection cards. Regular inspections are also called periodic inspections. The mechanical equipment should also be checked for accuracy to determine the degree of accuracy of the equipment.

Managed content:

Equipment maintenance work can be divided into routine maintenance and regular maintenance according to time; according to maintenance methods, it can be divided into general maintenance, regional maintenance and key equipment maintenance. Maintenance work includes: on-site management and maintenance work such as inspection, inspection, adjustment, lubrication, demolition and repair.

Application

Order Details

Item Name | Electric Eye HCCD Sensor |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Packing Size | 15cm*10cm*10cm,2kg/pc |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: what is linearity measurement, China, manufacturers, suppliers, factory, quotation, pricelist, buy