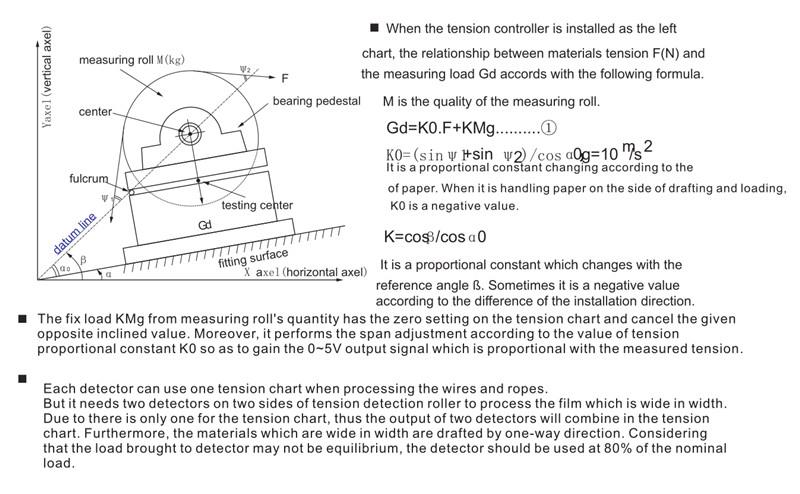

Winding Tension Calculation

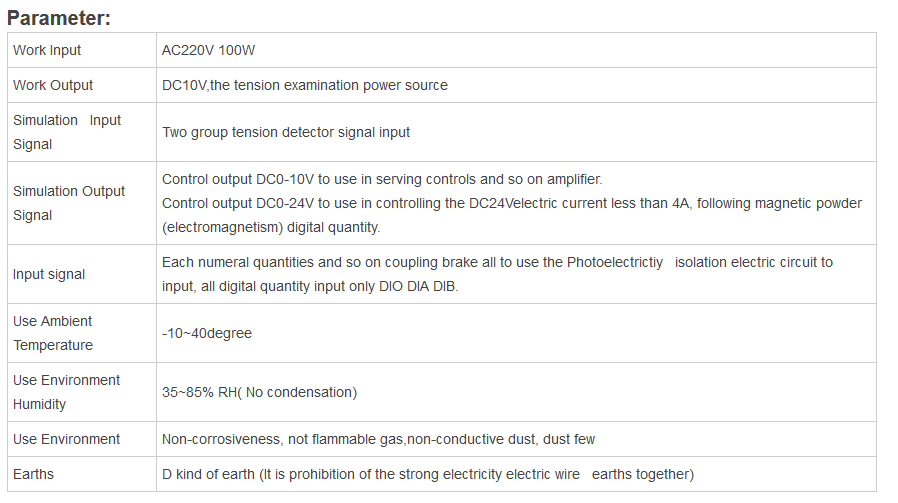

The automated anxiety controller is designed for the clicking The automated anxiety controller is designed for the printing press. it has outputs for pre-starting automatic shaft trade of the duplexer of the printing press, and has an automatic cutting and decreasing output characteristic, which...

The automated anxiety controller is designed for the clicking

The automated anxiety controller is designed for the printing press. it has outputs for pre-starting automatic shaft trade of the duplexer of the printing press, and has an automatic cutting and decreasing output characteristic, which can be appreciably utilized in numerous flexible and big-ranging applicability is needed for precise size and manipulate of hysteria.

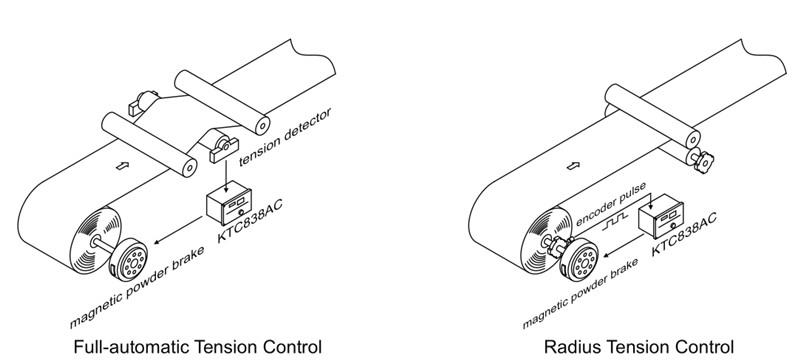

The automatic anxiety manipulate is to immediately diploma the real tension price of the material belt with the aid of the use of the tension sensor, after which convert the tension information right into a anxiety signal and feed it lower back to the tension controller. through using evaluating this signal with the preset anxiety rate of the controller, the manage signal is calculated. the automated control execution unit equalizes the real anxiety fee to the preset tension fee for anxiety stabilization purposes.

Tension controller realizes automatic control unwinding

The tension controller receives the signals transmitted by the two tension detectors, compares the set tension with the controller, and outputs the control magnetic powder clutch, brake, torque motor or servo motor to realize automatic control of unwinding or winding large size large diameter. The material tension device is especially suitable for printing machines, slitting machines, coating machines, laminating machines, etc. It has been widely used in the packaging, printing, labeling, paper, plastic, cable, non-woven, tire and rubber industries.

The tension controller will cause tensile deformation of the processed material; if the tension is too small, the stress between the layer and the layer of the material to be wound will be deformed, resulting in unwinding and affecting the processing quality. In the strip take-up system, the tension control system occupies an important position and it is quite complicated.

Automatic Tension Controller with Radius:KTC-838A

Anxiety controller for roll/rewind manage of coils

The anxiety controller is characterized with the aid of a nonlinearity of the magnetic powder capture/brake at low torque, and a completely unique torque repayment characteristic to make the anxiety curve flatter. the device form is straightforward and realistic, solid and dependable, and is appropriate for the receiving/unwinding manipulate of coils.

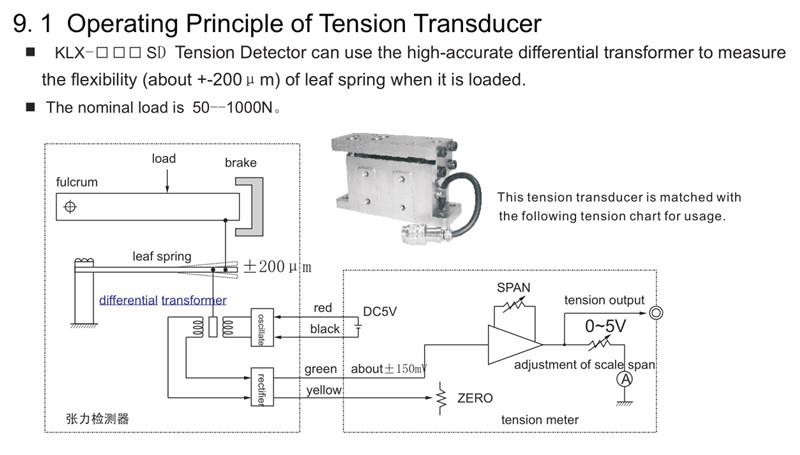

The tension controller may be operated best by manner of putting three simple parameters. the tension sensor lx collection detects the bending diploma of the leaf spring at the same time as the load is applied via the immoderate-precision detector, thereby detecting the anxiety, and has low temperature floating and excessive stability. diploma, proper linearity.

Automatic Tension Controller with Taper and Communication Function

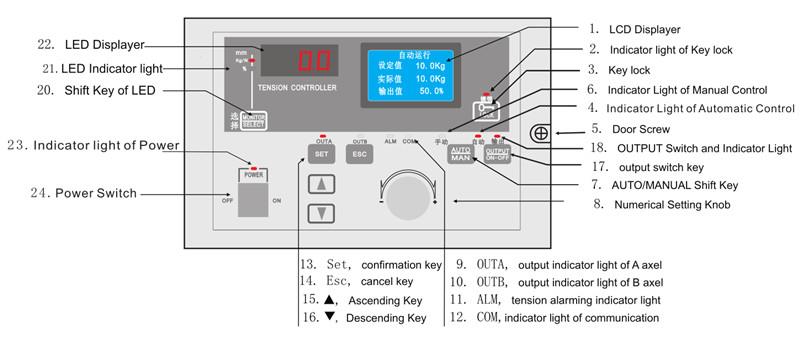

Operating Panel:

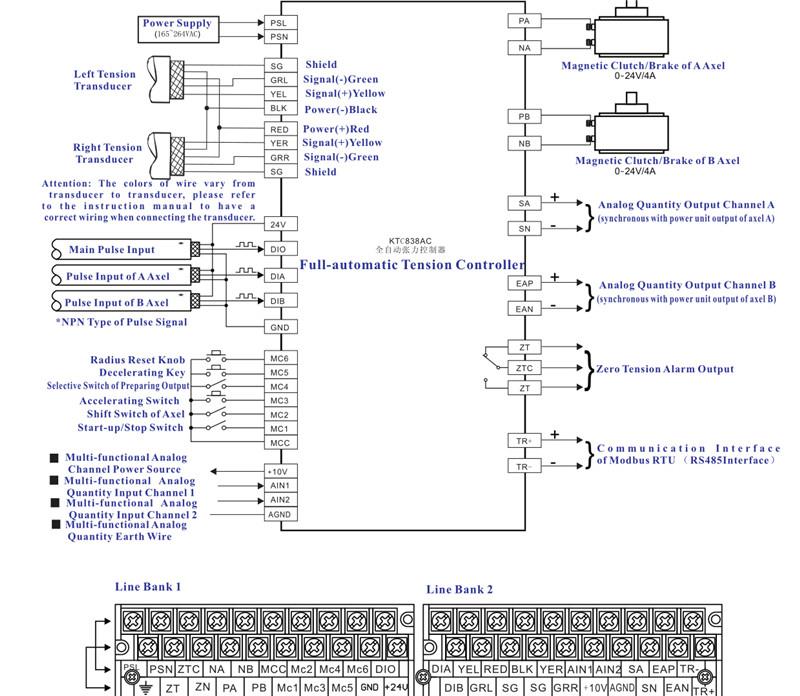

Wiring Diagram:

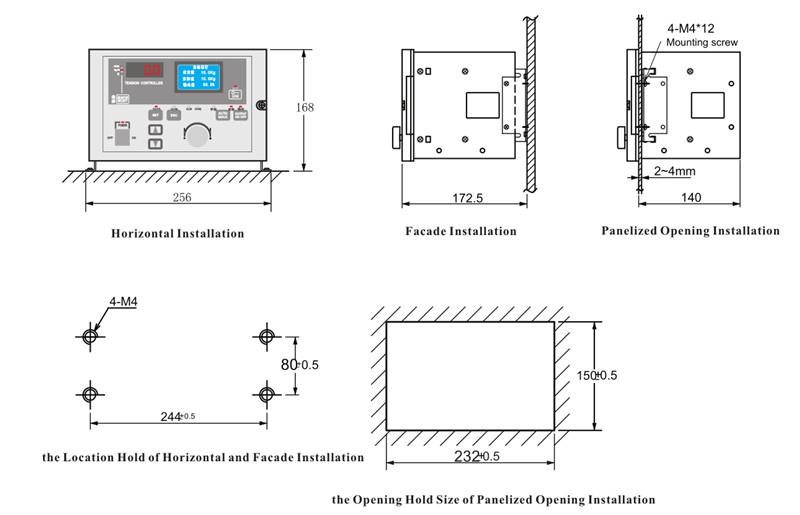

Installation:

The tension controller is a signal transmitted via receiving anxiety detectors

The tension controller receives the signals transmitted with the aid of the two anxiety detectors, compares the set anxiety with the controller, and outputs the manipulate magnetic powder clutch, brake, torque motor or servo motor to recognize computerized manipulate of unwinding or winding massive size large diameter. the material tension tool is specifically appropriate for printing machines, slitting machines, coating machines, laminating machines, and many others.

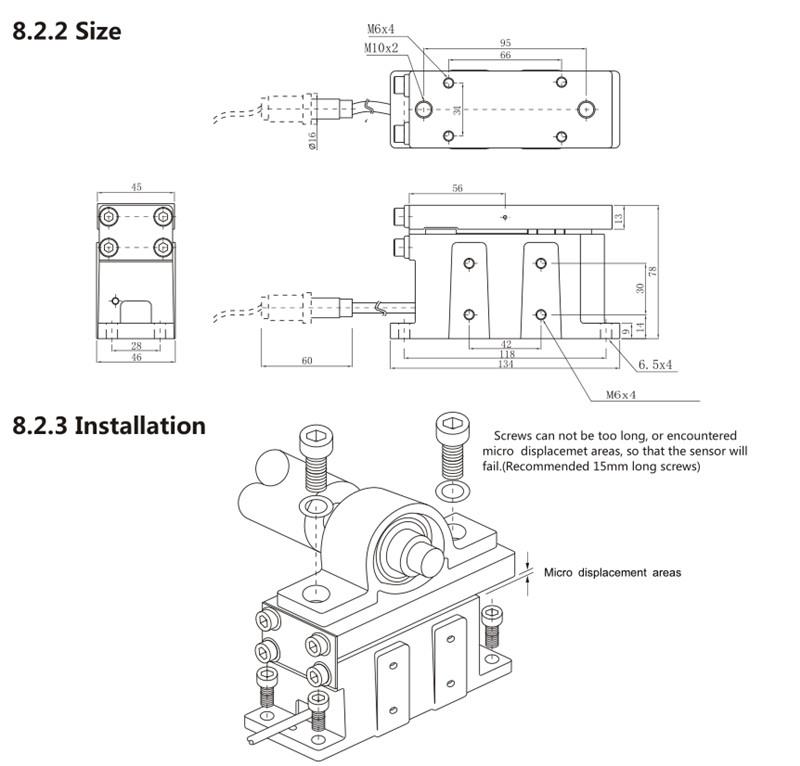

LX Foot-Mounted Tension Detector

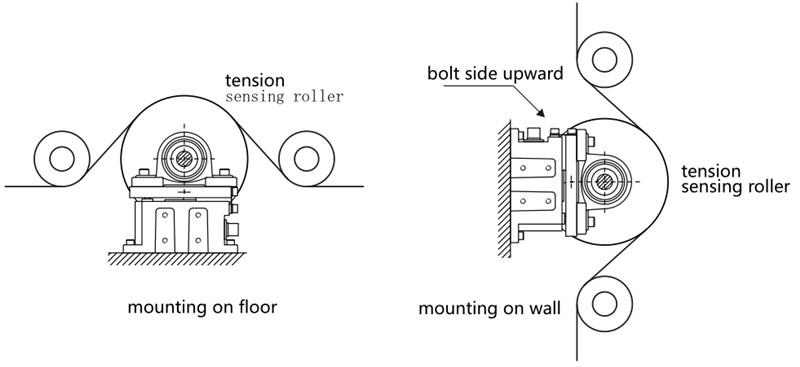

Mounting of Tension Sensors:

Order Details

Item Name | KTC-838A Automatic Tension Controller with Taper and Communication |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 2 days after receiving the deposit |

Calculated Packing Size | 20cm*15cm*15cm,2kg/pc |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: winding tension calculation, China, manufacturers, suppliers, factory, quotation, pricelist, buy