Winding Tension

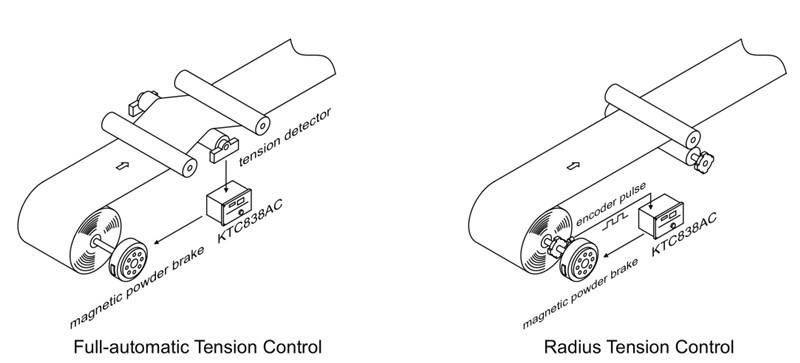

The primary function of the tension controller Normally, while the gadget is working, with the intention to ensure the rate of the device, a tension controller is often used to manipulate the jogging velocity of the system. this manipulate ought to be powerful for any velocity of the system,...

The primary function of the tension controller

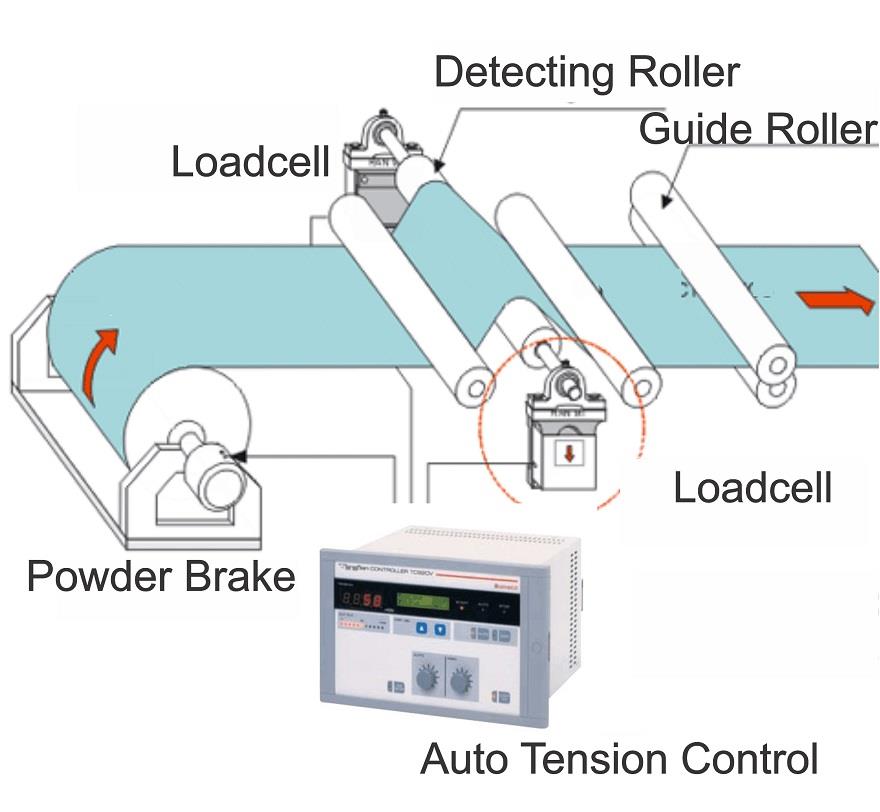

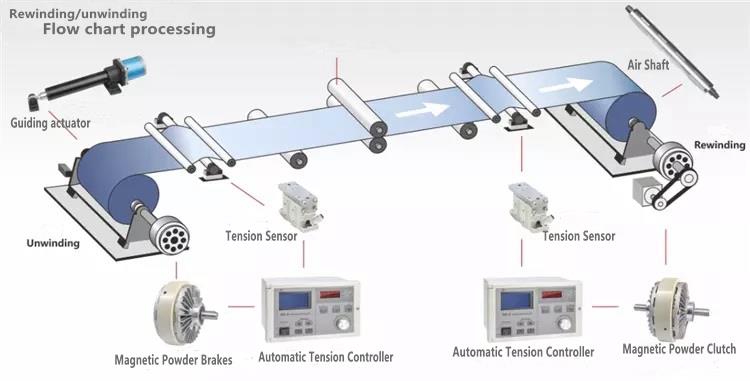

Normally, while the gadget is working, with the intention to ensure the rate of the device, a tension controller is often used to manipulate the jogging velocity of the system. this manipulate ought to be powerful for any velocity of the system, inclusive of acceleration, deceleration and regular velocity of the system. even inside the case of mechanical emergency braking, it need to be capable of make certain that the cut fabric is not damaged. the stableness of tension control is at once associated with the best of the slitting product. if the tension is insufficient, the uncooked fabric will glide for the duration of operation, and the finished paper will wrinkle after slitting and rewinding; if the tension is just too large, the uncooked fabric could be without problems broken, in order that the completed paper breaks after slitting and rewinding.

The primary characteristic of the anxiety controller: to achieve consistent anxiety control of the coil, or to attain taper control of the coil anxiety in step with the process necessities. anxiety controllers are commonly used to govern magnetic powder brakes, inverters, servo motors, and so forth. beneath normal occasions, there are many activities requiring steady anxiety manipulate; for taper manipulate, it's miles normally carried out within the case of winding, which includes reaching tight inner ring of the coil and unfastened outer ring, in order that the fabric isn't effortlessly deformed after being rolled up.

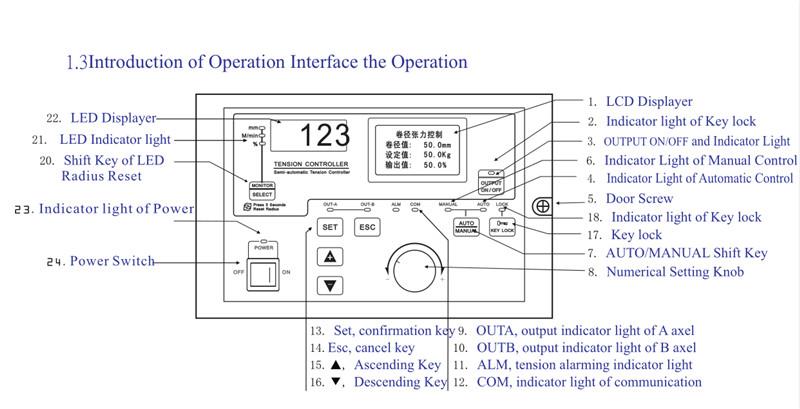

Semi Automatic Tension Controller: KTC818A

Power supply | AC85~264V 50/60HZ |

Rated output | DC24V 3A DC0~5V |

Input signal | DC12V Proximity switch (open) |

Roll diameter setting range | 1~2000mm |

Material setting range | 0.1~9999um |

Display | 7 segment LED (control output current coil diameter, etc) |

Control mode | Taper tension Acceleration, deceleration inertia supplement |

Working environment | Surrounding temperature: 0~+55°C |

Weight | About 3.5kg |

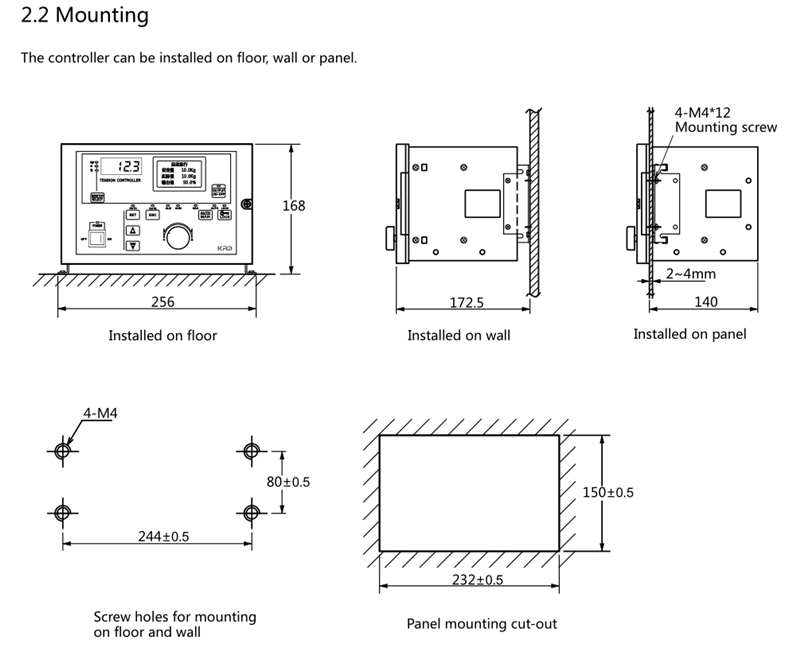

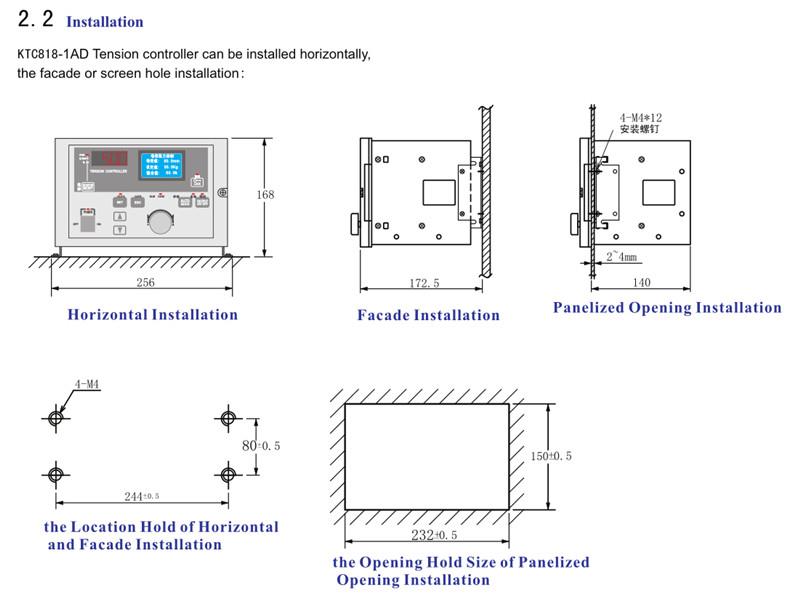

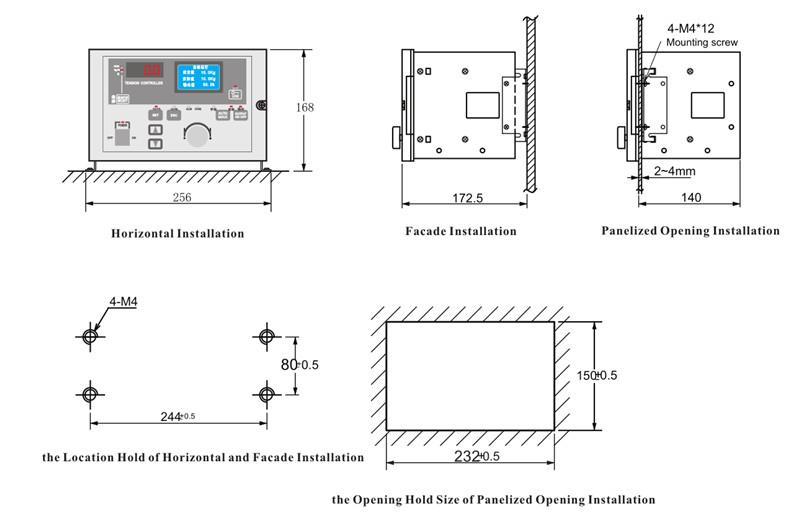

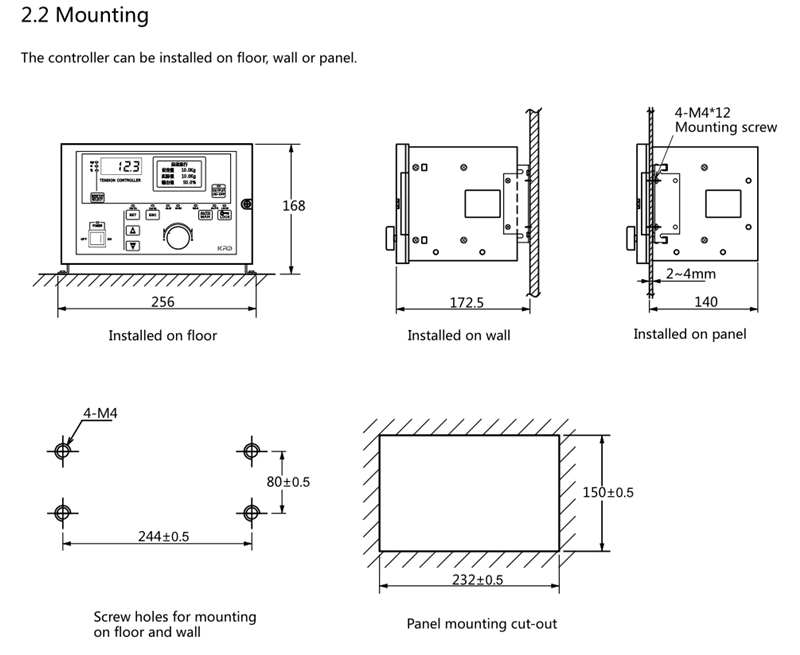

Installation | The ground, wall or screen installation |

Optional Accessories | If use ultrasonic induction or touch feeling, must configuration simulation tablet |

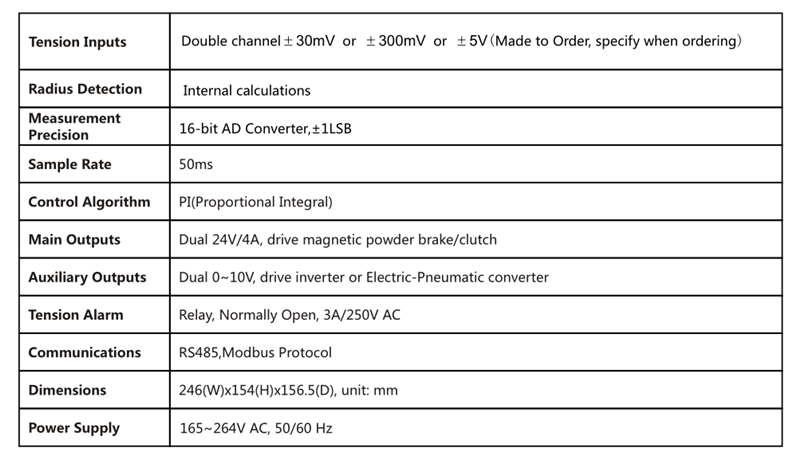

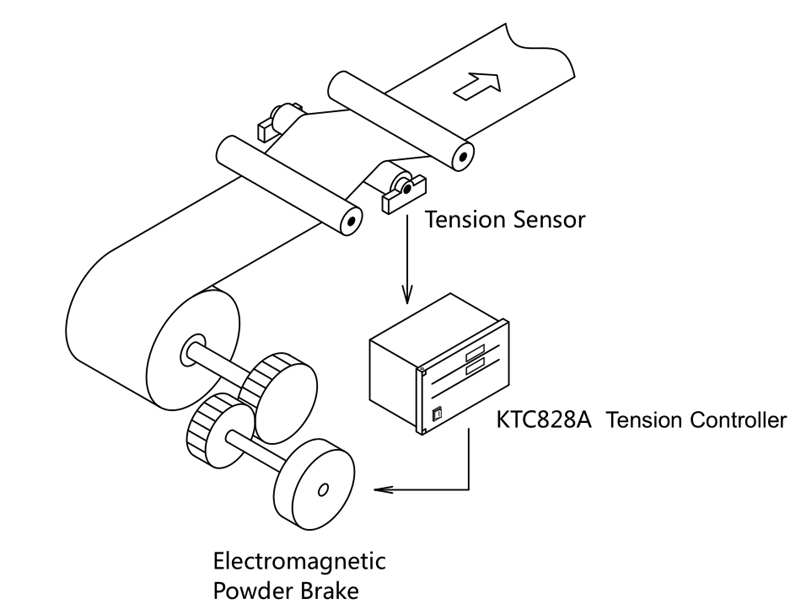

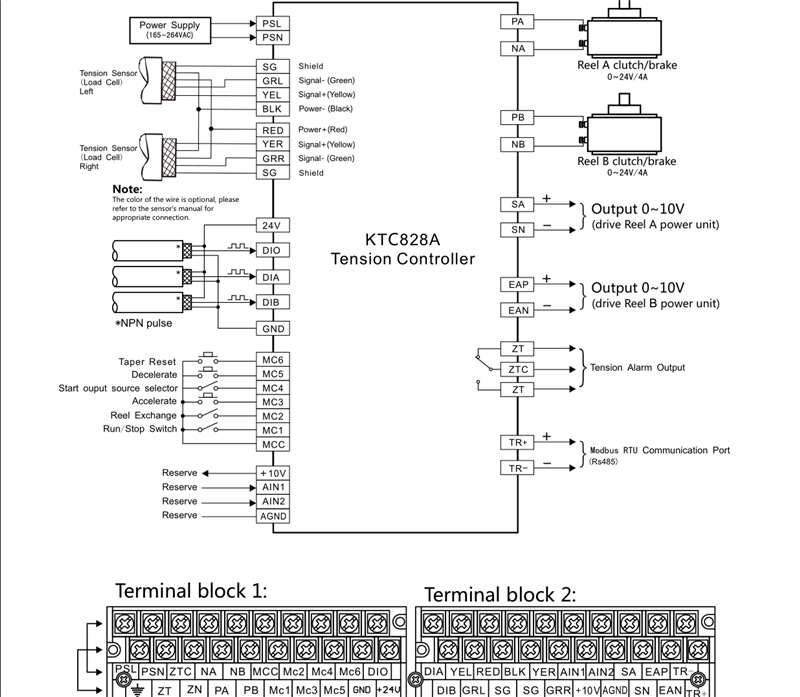

Automatic Tension Controller: KTC828A

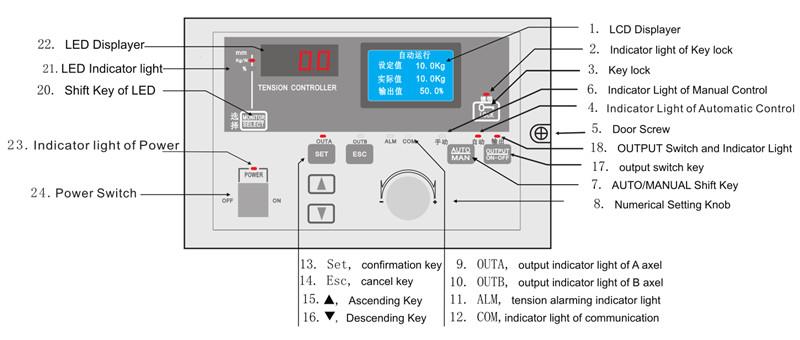

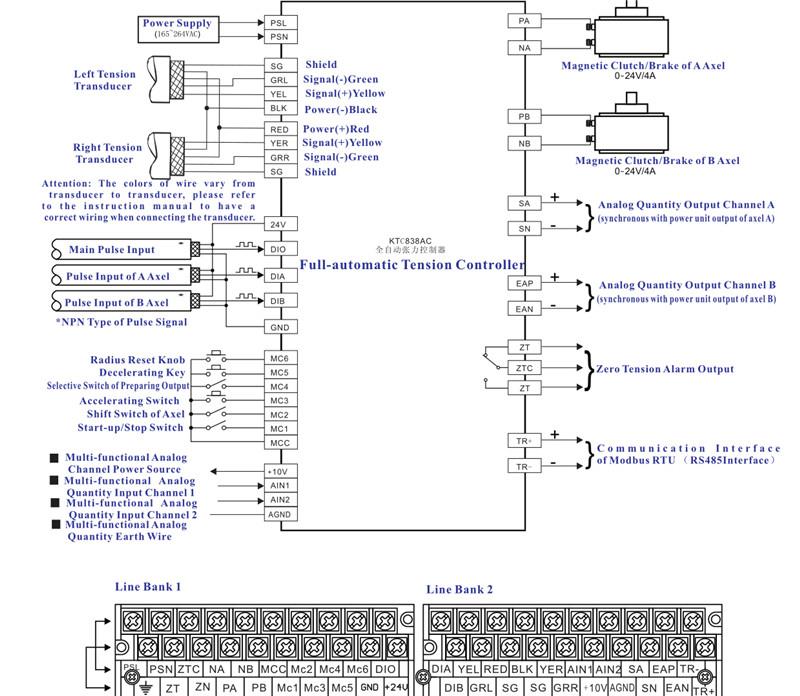

Automatic Tension Controller with Taper and Communication Function:KTC838A

Parameter:

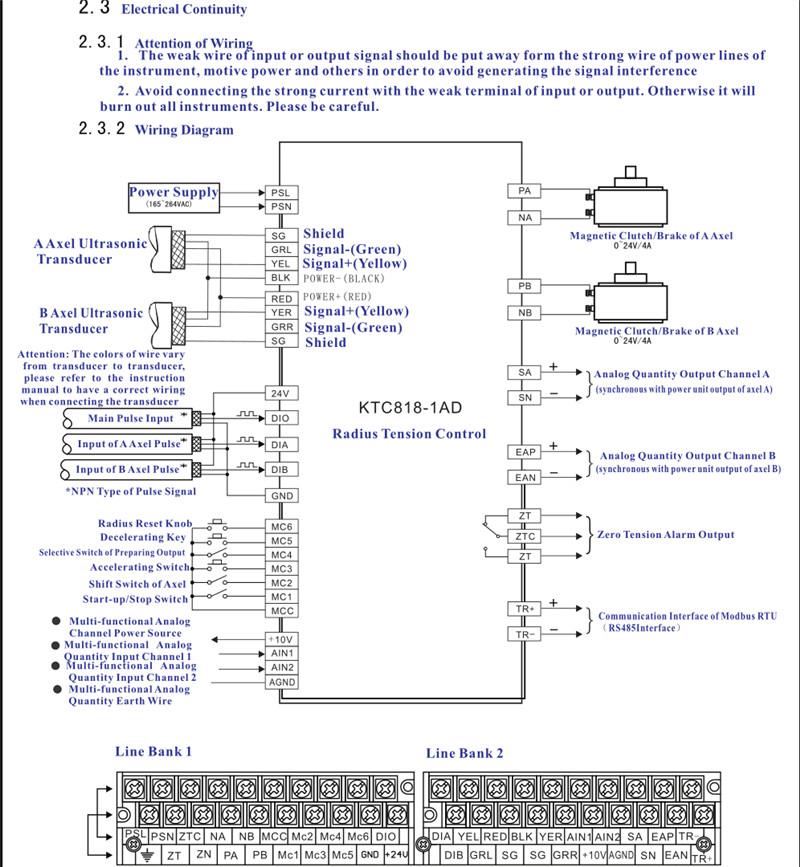

Work Input | AC220V 100W |

Work Output | DC10V,the tension examination power source |

Simulation Input Signal | Two group tension detector signal input |

Simulation Output Signal | Control output DC0-10V to use in serving controls and so on amplifier. |

Input signal | Each numeral quantities and so on coupling brake all to use the Photoelectrictiy isolation electric circuit to input, all digital quantity input only DIO DIA DIB. |

Use Ambient Temperature | -10~40degree |

Use Environment Humidity | 35~85% RH( No condensation) |

Use Environment | Non-corrosiveness, not flammable gas,non-conductive dust, dust few |

Earths | D kind of earth (It is prohibition of the strong electricity electric wire earths together) |

What are the causes and solutions for some of the failures of the automatic tension controller system in use?

Common causes of failure are:

1. It is highly probable that the detecting roller is not round, the bearing is damaged, and the detecting roller is bent;

2. There are problems with the magnetic powder brake, clutch and driver parts;

3. Sensor signal failure or calibration error.

Solution

1. Re-install the machine;

2. Replace the appropriate actuator;

3. Select the cooperative sensor and recalibrate it correctly.

Application

Order Details

Item Name | Automatic Tension Controller |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 2 days after receiving the deposit |

Calculated Packing Size | 20cm*15cm*15cm,2kg/pc(KTC-818A); 20cm*15cm*15cm,2kg/pc (KTC-828A); 20cm*15cm*15cm,2kg/pc(KTC-838A); |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: winding tension, China, manufacturers, suppliers, factory, quotation, pricelist, buy