Aluminum Foil Roller

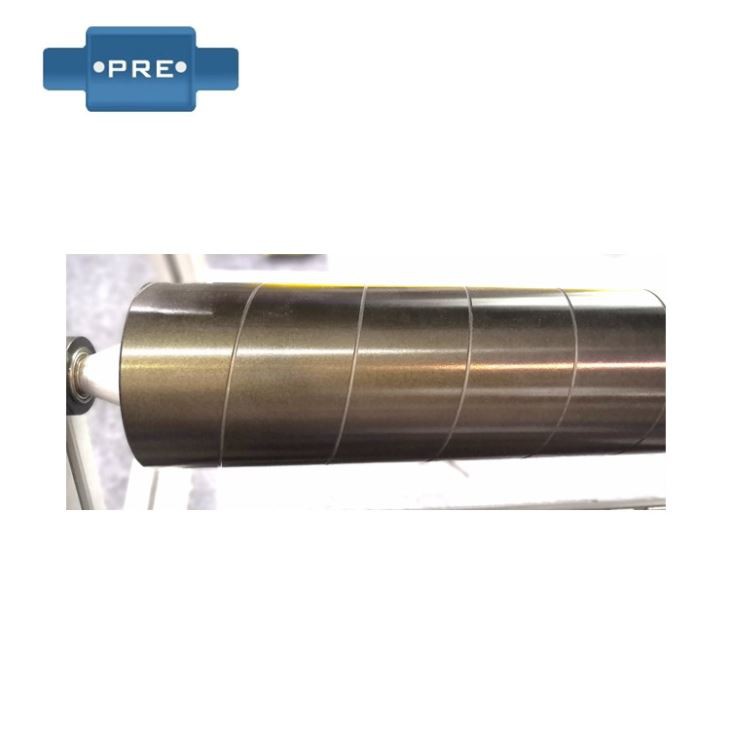

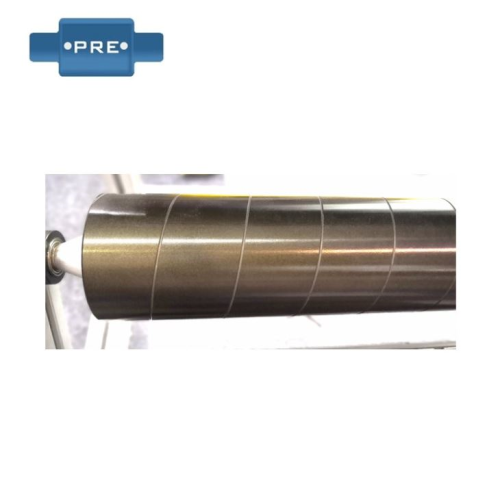

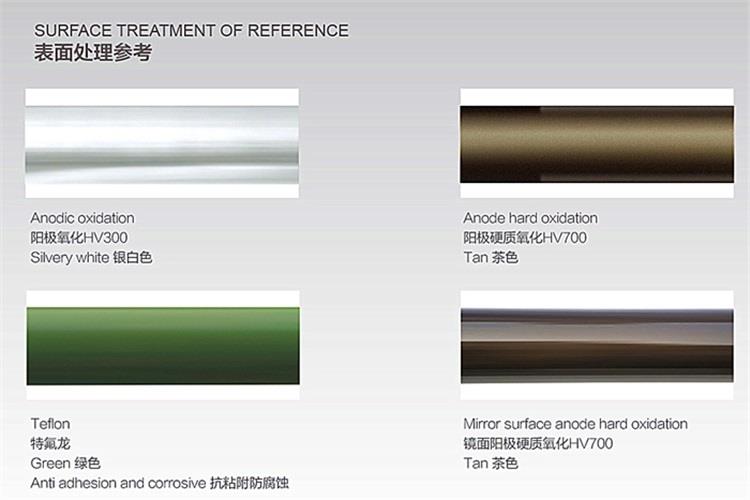

Brief introduction of the structure of aluminum guide roller From the surface structure of the aluminum guide roll body, it mainly consists of two parts: the mesh and the mesh wall; from the composition structure, it is mainly composed of the roll core, the base material and the surface plating....

Brief introduction of the structure of aluminum guide roller

From the surface structure of the aluminum guide roll body, it mainly consists of two parts: the mesh and the mesh wall; from the composition structure, it is mainly composed of the roll core, the base material and the surface plating. The commonly used material for the base material is electroplated copper, which is the basis for making the mesh and the mesh wall; the surface plating is made of metal chromium or ceramic, which mainly improves the wear resistance and the corrosion of the solvent to the base copper layer.

From the surface structure of the aluminum guide roll body, it mainly consists of two parts: the mesh and the mesh wall; from the composition structure, it is mainly composed of the roll core, the base material and the surface plating. The commonly used material for the base material is electroplated copper, which is the basis for making the mesh and the mesh wall; the surface plating is made of metal chromium or ceramic, which mainly improves the wear resistance and the corrosion of the solvent to the base copper layer.

Heating aluminum guide roller

It can directly process various lines and embossed patterns on the aluminum guide roll surface, without special pre-plated copper wall for the roll surface, long service life and uniform pattern, suitable for compound sizing, coating and ink transfer. , glazing, etc. Mainly used for sizing and coloring. Suitable for plastics, leather, leather, paper, carton machinery and other industries.

The as-cast microstructure of the mirror roll is austenite and a small amount of martensite. The carbide is mainly M7C3 type, and the shape is granular, massive, strip-shaped, and the distribution is relatively uniform, and it is not mesh-like. This kind of tissue has a macro hardness of HRC45-50, which has high impact toughness. Microhardness carbide (M7C3) HM1 422 - 1 813, matrix HM426 - 467.

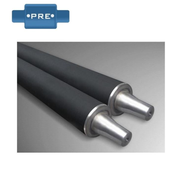

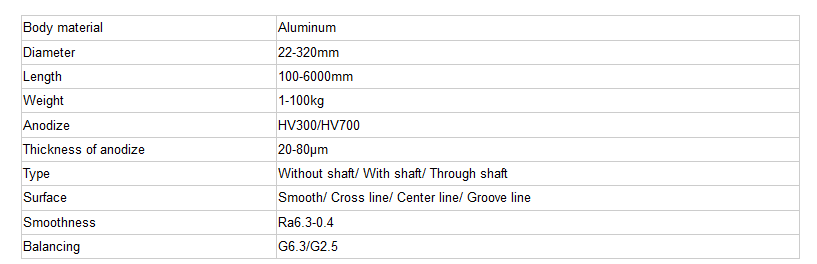

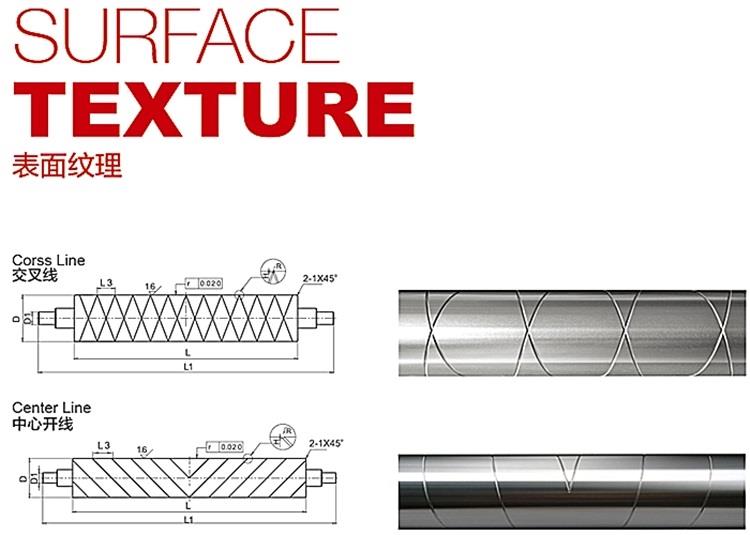

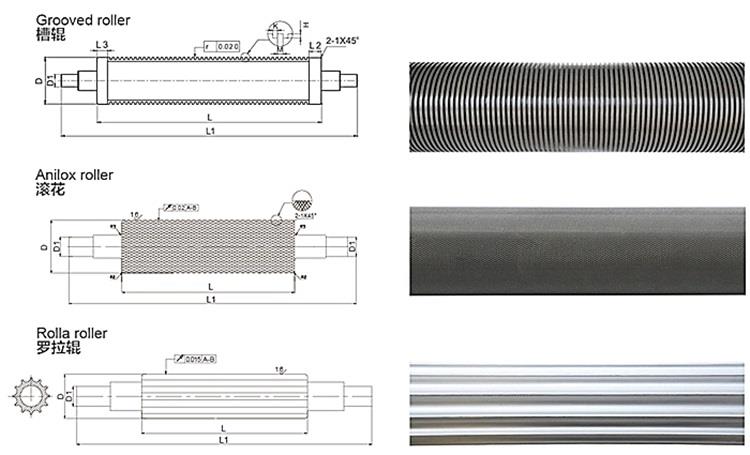

Different surface processing methods of aluminum rollers:

(1) Glossy surface: surface with smooth and low resistance, which can reach different surface roughness Ra0.3~Ra6.3 according to requirements

(2) Surface thread: Commonly used cross thread and center unfolding line (two points from the center, extending to both ends).

(3) Concave and convex surface: The concave, convex and arc-shaped surfaces can be machined by CNC lathe.

(4) Sand blasting or shot peening: sand blasting or shot peening can obtain a rough surface and increase friction.

(5) Knurling or network cable: Different sizes of flower surface can be provided according to customer requirements.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

Application

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum foil roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy