Channel Rollers

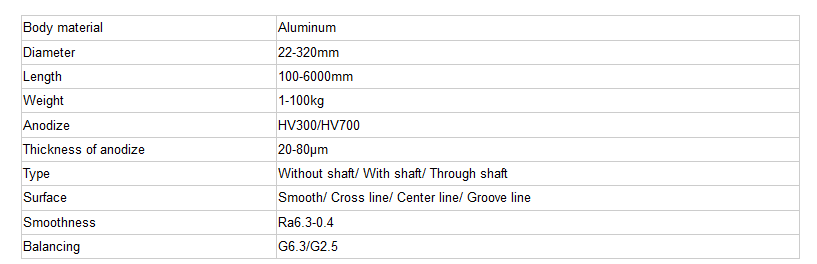

Common classification of rollers for aluminum guide rolls According to the action, the aluminum manual roller has a roller at the digital laser printer to make sure the transmission accuracy, and a calender roller at the papermaking machine that functions as a stress filter out, and has a assist...

Common classification of rollers for aluminum guide rolls

According to the action, the aluminum manual roller has a roller at the digital laser printer to make sure the transmission accuracy, and a calender roller at the papermaking machine that functions as a stress filter out, and has a assist curler that doesn't require high dimensional accuracy. there are rollers for warmth alternate, and rollers for heavy strain filtration, which aren't listed.

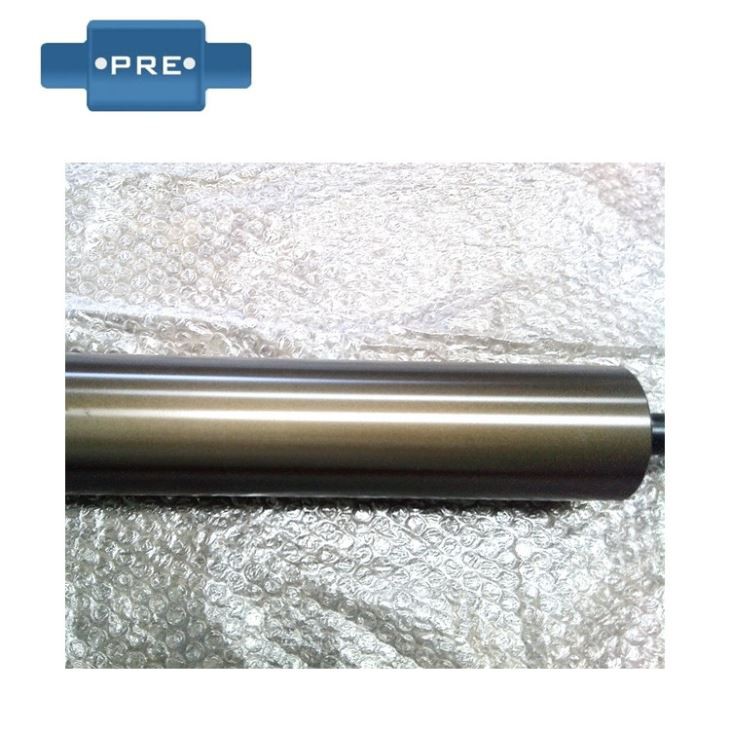

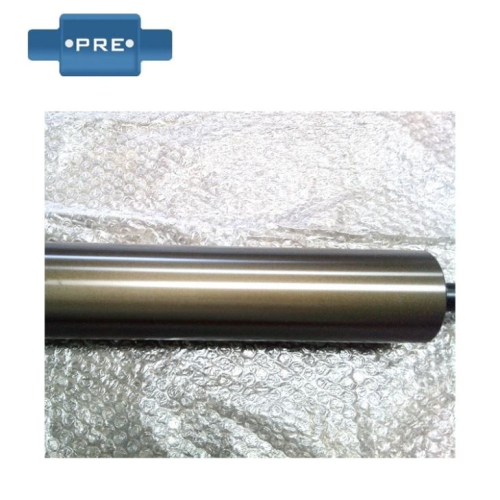

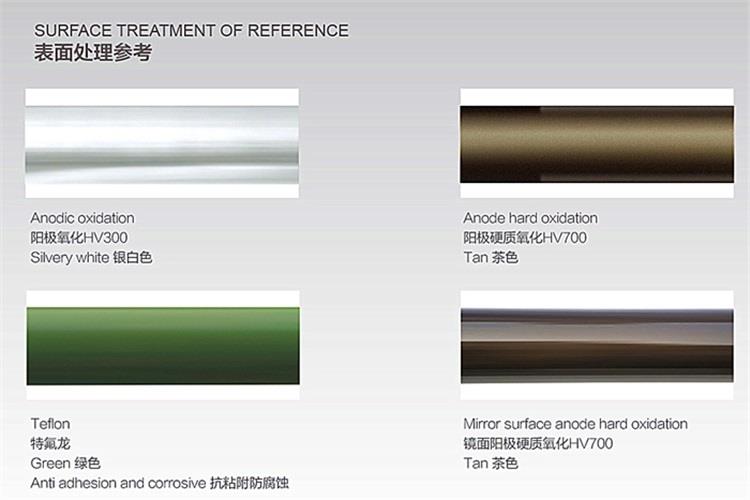

After the roll is formed, it desires surface treatment or coating including painting, galvanizing, teflon spraying, rubber coating, chrome plating, ceramic spraying and oxidation for the purpose of rust prevention, corrosion resistance, put on resistance and help.

Categorized via length, aluminum guide rolls have huge rolls including papermaking equipment (up to 10 meters in duration and 1500mm in diameter), and there are small flat rollers for belt conveyors on computerized meeting traces (typically in 1). in the length of the meter, the diameter is likewise inside 159mm)

Consistent with the action, the aluminum manual roller has a curler at the virtual laser printer to make sure the transmission accuracy, and a calender curler at the papermaking device that functions as a strain filter out, and has a support curler that doesn't require high dimensional accuracy. there are rollers for heat alternate, and rollers for heavy strain filtration, which aren't indexed.

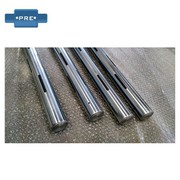

Roller diameter selection: 25mm, 32mm, 38mm, 42mm, 50mm, 57mm, 60mm, 76mm, 80mm, 89mm. roller cloth choice: carbon steel galvanizing, carbon metal chrome plating, carbon steel rubber, aluminum alloy, stainless steel, abs, etc.

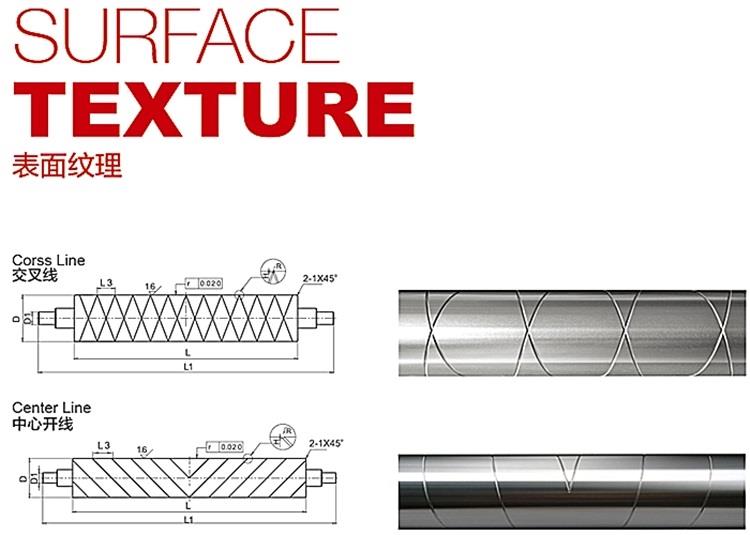

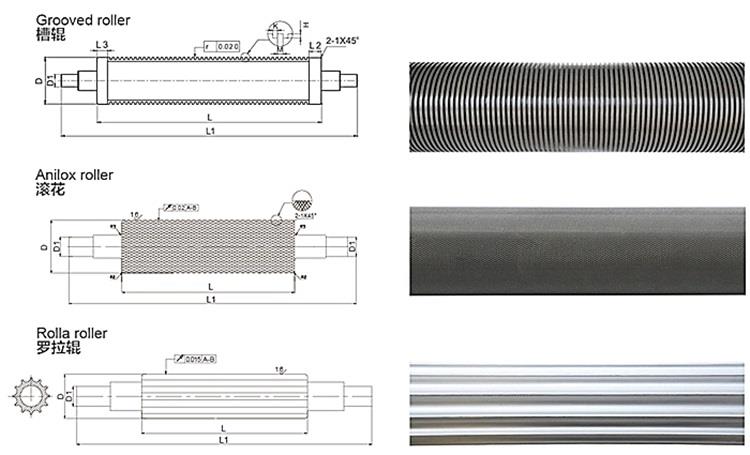

Curler type choice: no electricity curler, unmarried chain curler, double chain roller, "o" belt roller, conical roller, grooved roller. curler fixing technique: spring press kind, inner shaft type, full flat kind, thru shaft pin hole kind.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

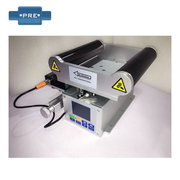

What is the role of the roller of the aluminum guide roller?

The roller of the aluminum guide roller is an important part of the belt conveyor, and has many types and a large number. Although the rollers of the aluminum guide rolls are a small part in the belt conveyor and the structure is not complicated, it is not easy to manufacture a high quality idler.

The roller of the aluminum guide roller serves to support the conveyor belt and the weight of the material. The roller must be flexible and reliable. Reducing the friction between the conveyor belt and the idler roller plays a key role in the life of the conveyor belt, which accounts for more than 25% of the total cost of the conveyor.

The criteria for judging the quality of the rollers are as follows: the amount of radial runout of the idler; the flexibility of the idler; the amount of axial turbulence. The roller of the aluminum guide roller is an important part of the belt conveyor, and has many types and a large number. It accounts for 35% of the total cost of a belt conveyor and withstands more than 70% of the resistance, so the quality of the rollers is particularly important. Although the rollers of the aluminum guide rolls are a small part in the belt conveyor and the structure is not complicated, it is not easy to manufacture a high quality idler.

If the aluminum roller is poorly lubricated, it will cause the wear and the gap of the printing plate aluminum roller roller head and the bearing to increase, resulting in uneven printing on the ink.

How do we go to lubricate aluminum rolls in our daily routine? In fact, the printing plate roller head and bearing should always maintain effective lubrication. If the lubrication is poor, it will cause the wear of the printing plate aluminum roller roller head and bearing, the gap will increase, and even cause uneven printing on the ink. Printing plate roller jump and sliding and other unfavorable conditions cause printing bar marks. If there is no effective lubrication for continuous operation for a long time, the bearing and the shaft core will heat up, causing the rubber surface of the printing plate roller to be thermally expanded and worn, so that the two rubber faces are worn. Produce pockmarks, gums, cracks.

Application

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: channel rollers, China, manufacturers, suppliers, factory, quotation, pricelist, buy