Conveyor Drive Aluminum Idler Vibration Roller

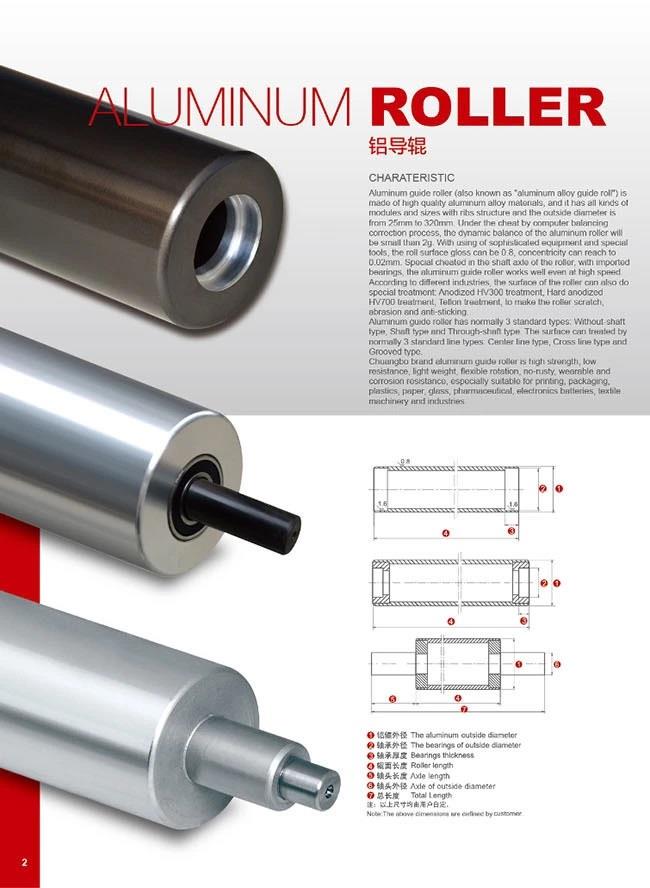

1.Aluminum roller adopts the high quality of aluminum, and use advanced processing technology 2.the surface is using anodic oxidation treatment, we have two types of this product : HV300 (white) or HV700 (twanty), roll body smooth finish is 0.8, dynamic balance is G2.5; 3.Aluminum tube generally...

1.Aluminum roller adopts the high quality of aluminum, and use advanced processing technology

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

The structure of the aluminum roller can be roughly divided into:

1. Hollow aluminum roller: The inner bearing type structure, the bearing is assembled on the bearing holes at both end faces.

2. Coupling aluminum roller: The two ends of the roller body are combined with steel shaft or stainless steel shaft end, which is an integrated structure.

3. Water-passing aluminum roller: cooling or heating liquid enters and exits through both sides and circulates in the roller body.

4. Special Roller: A variety of special structural rolls processed according to the drawings.

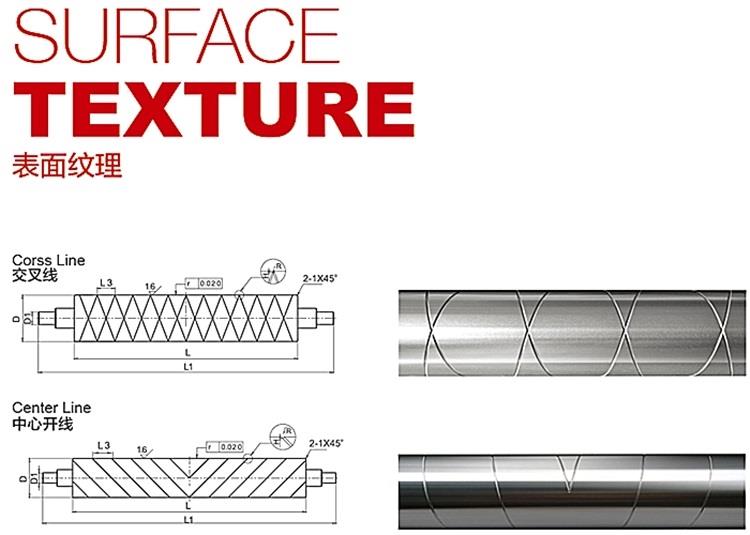

Different surface processing methods of aluminum rollers:

1. Glossy: Surface with smooth and low resistance, can achieve different surface roughness Ra0.3~Ra6.3 according to requirements

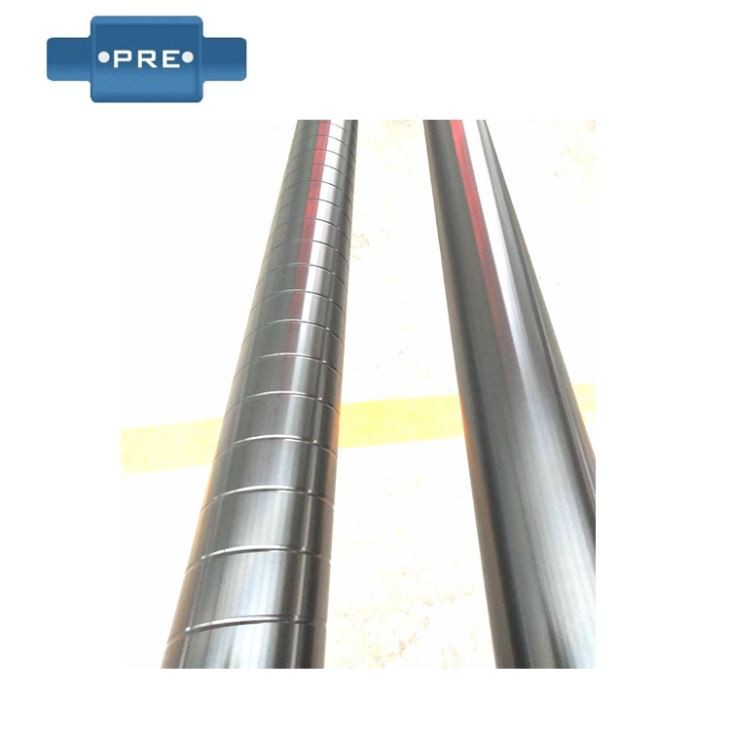

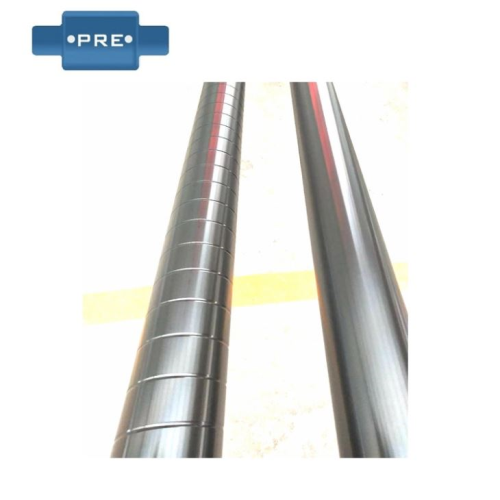

2. Surface thread: Commonly used cross thread and center unfolding line (two points from the center, extending to both ends).

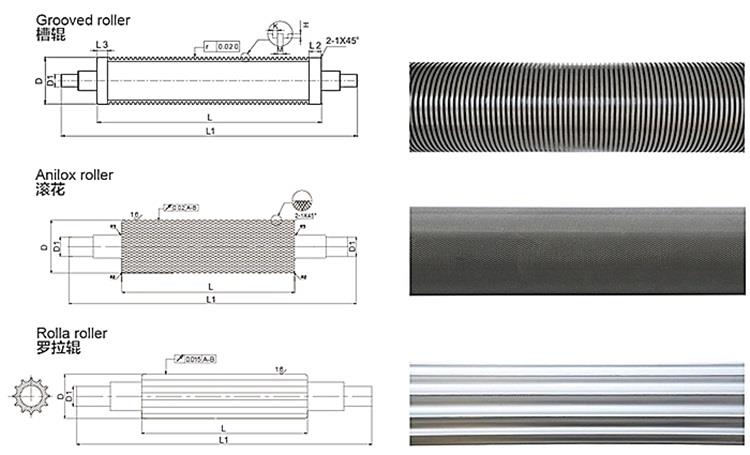

3. Concave and convex surface: Various concave, convex and arc-shaped surfaces can be processed by CNC lathe.

4. Sand blasting or shot peening: sand blasting or shot peening can obtain a rough surface and increase friction.

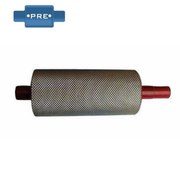

5. Knurling or network cable: Different sizes of flower surface can be provided according to customer requirements.

The roller of the grooved roller is extruded by high-quality aluminum alloy. The built-in nine reinforcing ribs and wall thickness have strengthening effect. The wheel surface adopts new technology and the anode is hardened to ensure its rigidity and wear resistance. It introduces advanced computer balance and correction. Its balance is up to 2g.

Using special tools and measuring tools, the surface roughness of the roller is up to 0.8 and the coaxiality is 0.02mm. The reasonable shaft connection method can be easily operated and never changed at any running speed.

This product has high strength, low resistance, corrosion resistance, light weight, smooth rotation and no rust.

Aluminum guide rolls are the preferred choice in printing machinery systems.

Application

How do we go to lubricate aluminum rolls in our daily routine?

In fact, the printing roller head and bearings should always be effectively lubricated.

If the lubrication is poor, it will cause the wear of the printing plate aluminum roller roller head and the bearing, and the gap will increase, resulting in uneven printing on the ink.

At the same time, the printing bar marks may be caused by defects such as the printing plate jumping and sliding.

If there is no effective lubrication for a long time continuous operation, the bearing and the shaft core will be heated, causing the rubber surface of the printing plate to be thermally expanded and worn, so that the rubber surface of the two heads is pocked, glued and cracked.

Packing

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients' demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: conveyor drive aluminum idler vibration roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy