Conveyor Roller

The non-powered conveying roller, also called the free roller, is composed of a cylinder, a shaft core, a deep groove ball bearing and a bearing mounting frame. In use, it is used for auxiliary rolling, and has no power and is rolled by external force. There are drive rollers generally referred...

The non-powered conveying roller, also called the free roller, is composed of a cylinder, a shaft core, a deep groove ball bearing and a bearing mounting frame. In use, it is used for auxiliary rolling, and has no power and is rolled by external force.

There are drive rollers generally referred to as built-in motor drums. Here we also refer to rollers with sprocket wheels, timing pulleys, etc. that can be driven by geared motors. The structure is basically the same as that of no power, except that the motor is built in or a sprocket or timing pulley is added to the outside to drive other components that can be driven by the geared motor.

Roller Diameter mm | Roller length mm | Bearing | roller shell thick mm |

76 | 160-950 | 6204 | 3.0-4.5mm |

89 | 160-950 | 6204 | |

102 | 160-950 | 6204 | |

108 | 250-1600 | 6305 | |

114 | 160-1753 | 6305 | |

121 | 160-1753 | 6305 | |

127 | 160-1753 | 6305 | |

133 | 250-2500 | 6305 | |

152 | 160-2500 | 6305 6306 | |

159 | 315-2800 | 6305 6306 | |

178 | 315-2800 | 6305 6306 | |

219 | 315-2800 | 6305 6306 | |

Roller Seals

Seal type: DTII type seall, labyrinth seals

![S}GA4C8B]{$VY1NZYZDUG~E S}GA4C8B]{$VY1NZYZDUG~E](png/201910180953149780683.png)

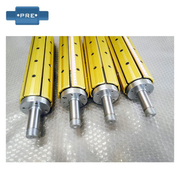

Composite rollers structure features

Composite roller is made of composite shell, composite material bearing seat, metal shaft, bearings and DTII type seals.

Rollers are widely used in various types of transmission conveying systems and sorting and conveying equipment such as rotary screen printing machines, digital printers, mining conveyor equipment, paper making and packaging machinery. In order to extend the service life of the drum during the use of the roller, the maintenance of the drum must be done.

1. Regularly clean foreign matter such as dust on the rollers.

2. Regularly check that the weld between the drum shell and the end cap is secure.

3. Good lubrication and reduce wear loss.

4. Avoid overloading and extend drum life.

Packing & Delivery

Order Details

Item Name | Conveyor Rollers |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients’demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: conveyor roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy