Good Web Guide

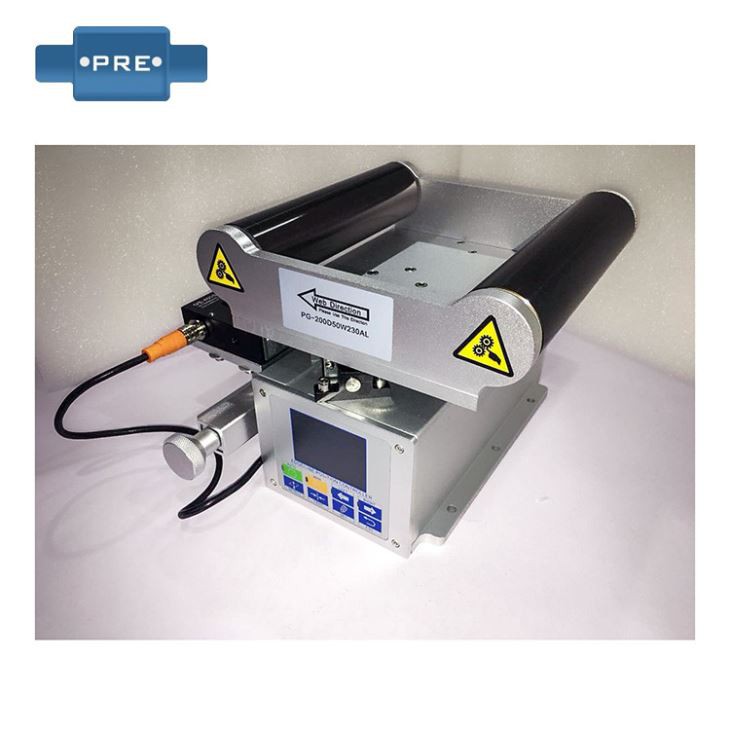

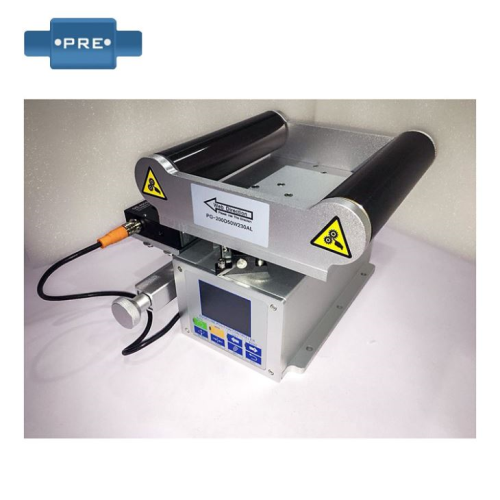

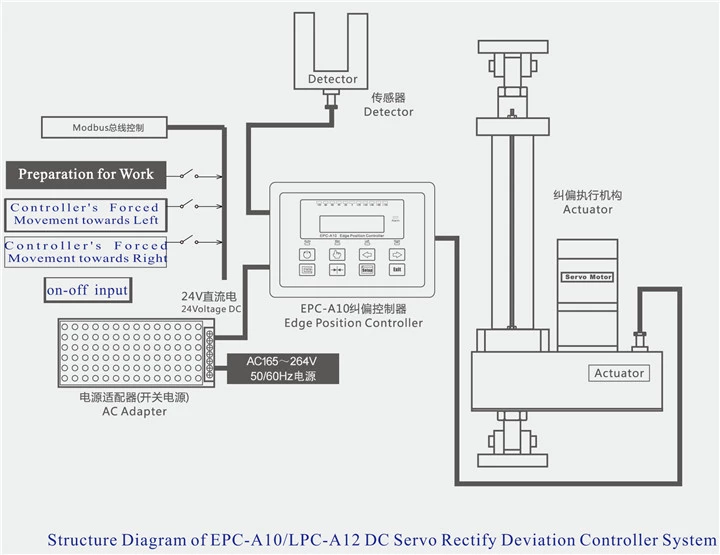

The coil rectification control system is a closed-loop control system, controller, sensor, and linear guide mechanism. It is the basic part of closed-loop control. Firstly, the rectification sensor detects the edge or line of the coil, and reads the actual position of the coil and the deviation...

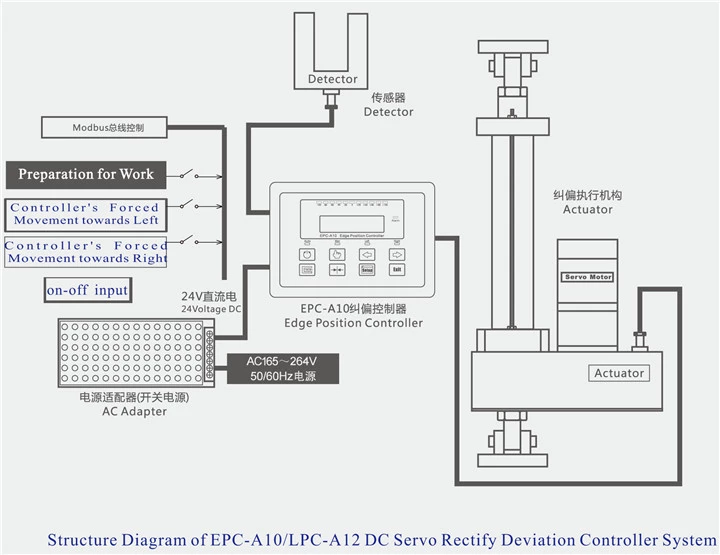

The coil rectification control system is a closed-loop control system, controller, sensor, and linear guide mechanism. It is the basic part of closed-loop control. Firstly, the rectification sensor detects the edge or line of the coil, and reads the actual position of the coil and the deviation of the set position. The amount of shift is converted into an electrical signal proportional to it, and then the electrical signal is sent to the controller. The signal is amplified and calibrated by the controller, and then output to the linear driver. The linear driver drives the corrective guide according to the magnitude of the signal. The positive mechanism restores the coil to the set position. The drive signal of the current drive is only proportional to the amount of deflection of the coil, which allows precise control of the various coils and Guide systems.

Guide controller refers to the technical operation taken by the manufacturer to keep the side of the coil consistent during the spraying, printing, punching, laminating, slitting or other coil winding process. Because the edge of the coil is not aligned, it will cause subsequent step errors, resulting in material waste or downtime adjustment. Therefore, when processing the processed coil, it is necessary to perform a timely correcting operation on the offset coil, which is called rectification. The entire process of the device constitutes a set of guide systems.

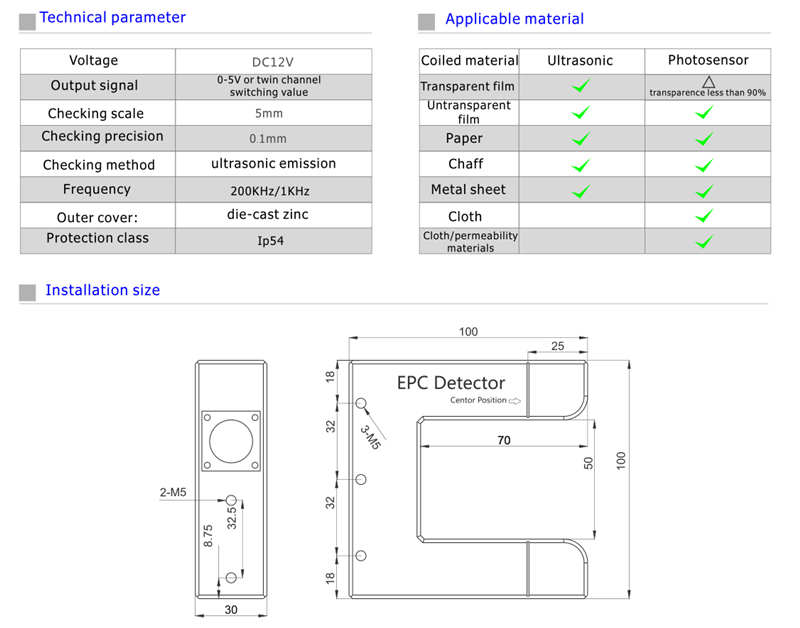

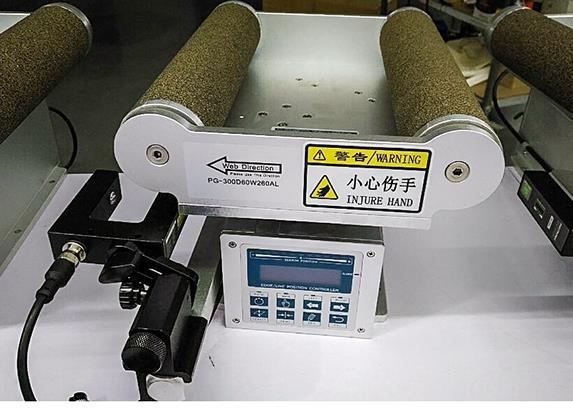

Guide systems are extremely diverse and are essential in the packaging, printing, labeling, construction materials, pulp, household paper, plastics, garments, cables, metal processing, nonwovens, corrugated paper processing and other industries. A typical guide system includes a guide controller, a guide sensor, a guide frame, and a driver.

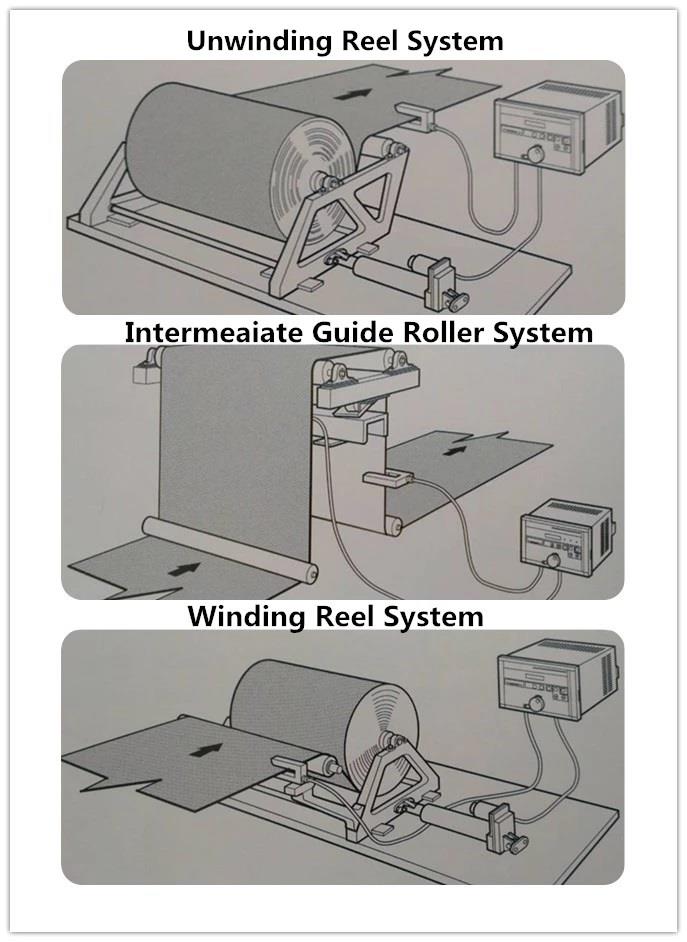

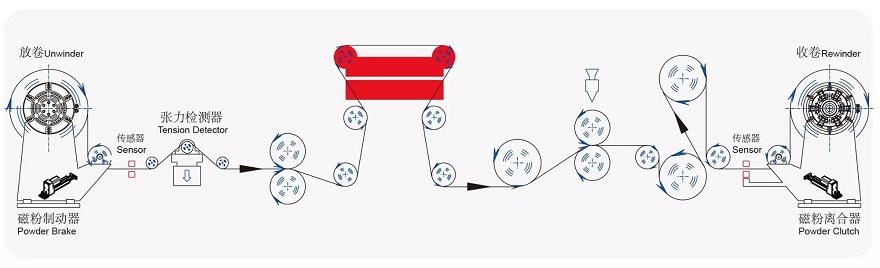

Unwinding guide:

Three typical applications of the guide system: ensure that the coil is always exported from a pre-set position during the unwinding process in order to accurately enter the next process.

The irregular coiled material is edge-aligned and sent to the next process, such as printing, slitting, coating, lamination, and the like. The edge sensor is fixed in advance to the position to be aligned, the offset of the edge of the web is detected, and fed back to the controller, and the controller outputs a signal to the motor driver to control the movement of the spool so that the edge of the coil is always in this position.

Intermeaitate Guide Roller System:

Winding guide: Ensure that the curling is neat during the winding process.

Align the edges of the web and roll them up. The edge sensor is attached to the take-up reel and a fixed reel is mounted between the sensor and the take-up reel. You don't have to worry about the offset of the web, because the sensor that is attached to the reel always tracks its edges so that it can align the edges of the web and roll up.

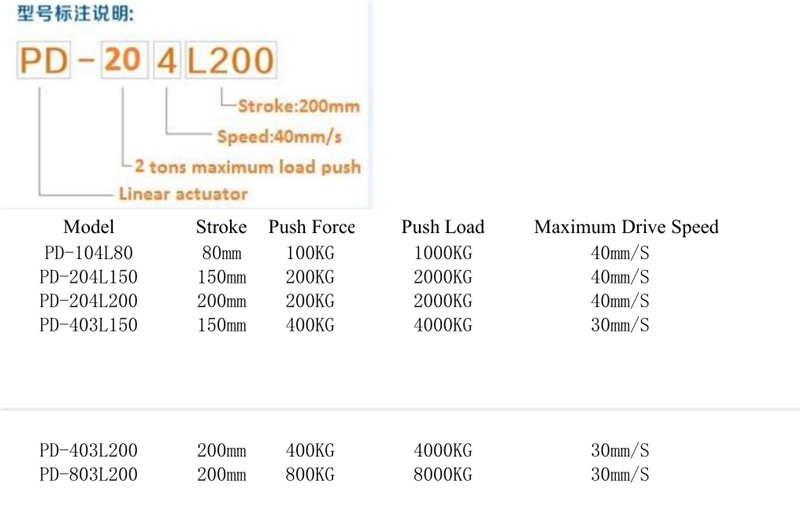

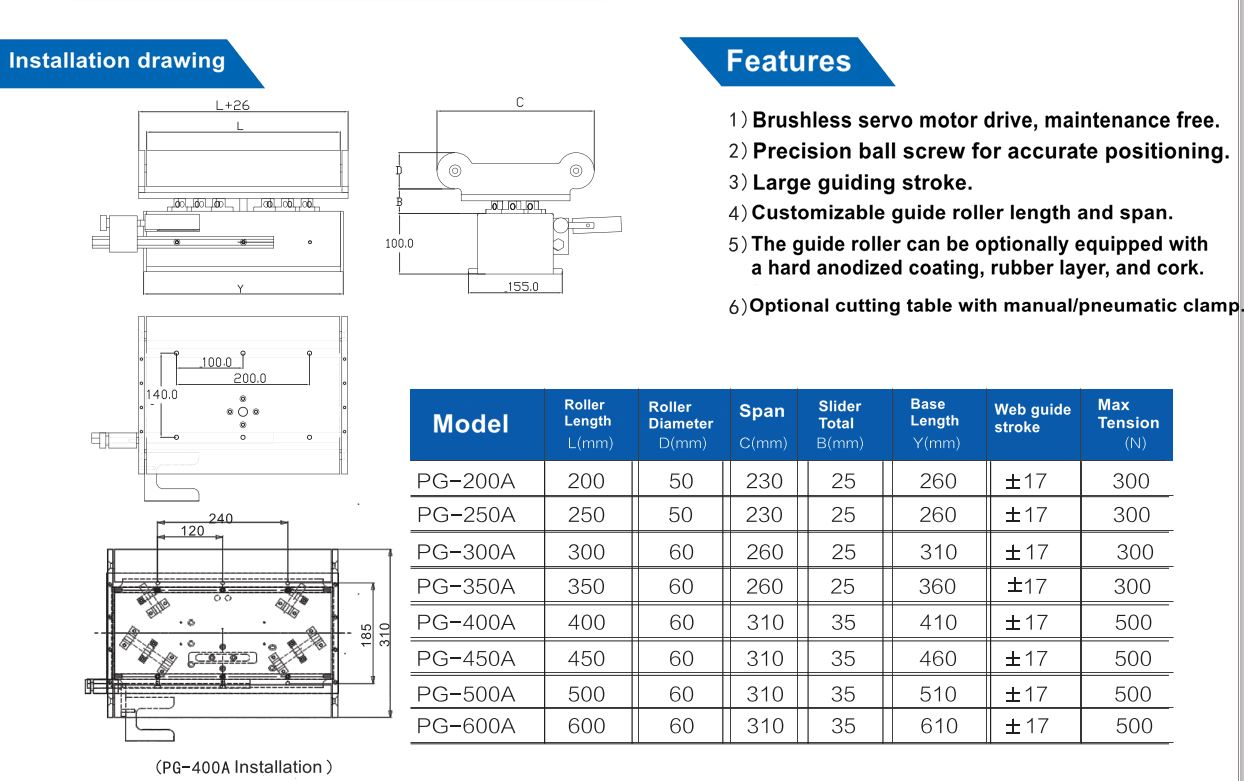

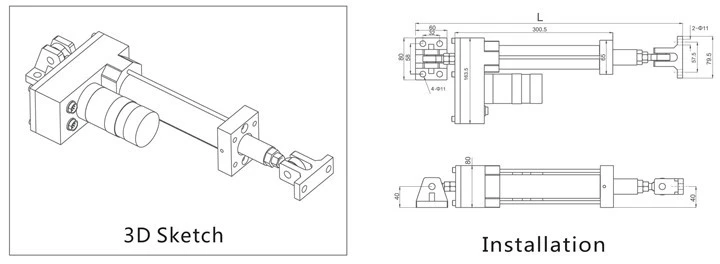

Servo Motor Linear Driver Parameter:

| Model | Travel | Thrust | Pushing loading | Max. driving speed |

| PD-104L80 | 80mm | 100kg | 1000kg | 40mm/s |

| PD-204L150 | 150mm | 200kg | 2000kg | 40mm/s |

| PD-204L200 | 200mm | 200kg | 2000kg | 40mm/s |

| PD-403L150 | 150mm | 400kg | 4000kg | 30mm/s |

| PD-403L200 | 200mm | 400kg | 4000kg | 30mm/s |

| PD-803L200 | 200mm | 800kg | 8000kg | 30mm/s |

Apllication

Why do you need a coil guide control system?

Reel material refers

to long continuous materials such as paper, film, sheet, cloth, metal

foil, wire, wire, and the like. During the processing of the coil

material, the coil material needs to be subjected to unwinding, process

processing, winding, and the like. During this series of operations, the

deviation of the coil may occur due to the deviation of the coil itself

or the equipment. The guide control system is designed to reduce the

occurrence of such situations. The position of the coil is always

tracked during the production process and corrected in real time,

ensuring and improving production quality and efficiency without manual

intervention.

Order Details

Item Name | Web Guide Control System |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | depends on the model |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: good web guide, China, manufacturers, suppliers, factory, quotation, pricelist, buy