Magnetic Particle Brake

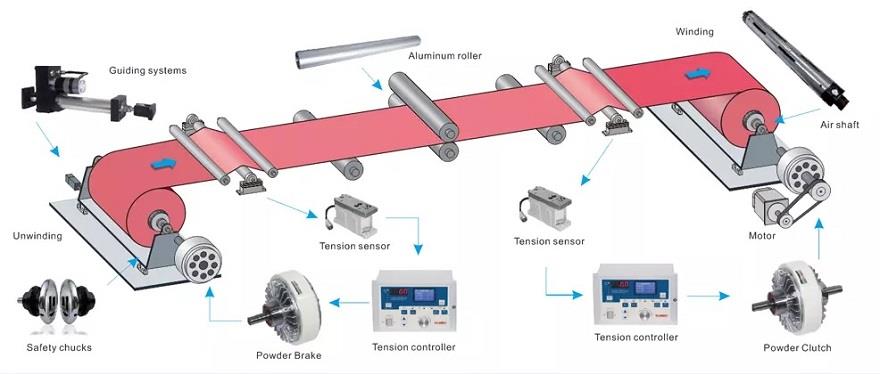

Magnetic powder brakes and magnetic powder clutches are used in a wide range of applications, including high-speed extruders for wire and cable equipment, high-speed stranding machines, extrusion lines, shaftless payoffs, single stranders, twisted pairs, and wire cutters. Series production...

Magnetic powder brakes and magnetic powder clutches are used in a wide range of applications, including high-speed extruders for wire and cable equipment, high-speed stranding machines, extrusion lines, shaftless payoffs, single stranders, twisted pairs, and wire cutters. Series production lines, insulation production lines, etc., while pneumatic brakes are also one of the most common brakes in the wire and cable equipment industry.

The magnetic powder brake device is controlled by the tension controller on the unwinding unit of the coating machine according to the tension signal generated by the tension detector detecting the tension of the strip. The magnetic powder brake is more widely used in the automatic pressing of printing, packaging and textile machinery. Flat die cutting machine, automatic paste folding machine, sheetfed offset printing machine, automatic die cutting machine, film laminating machine, slitting machine, paper bag machine, gravure printing machine, cloth inspection machine, textile machine, coating machine, peritoneal machine And metal processing machines and other fields.

The main function of the magnetic powder brake for the coating machine is to transmit a stable tension to the unwinding unit to ensure uniform coating. The magnetic powder clutch controls the tension of the film when it is mounted on the unwinding roller. Its main function is that the sliding torque can be arbitrarily changed by changing the magnitude of the exciting current when the state is tilted, so it does not need to be adjusted as much as mechanical braking. Using high-quality materials, non-magnetic saturated structure and reasonable magnetic circuit design, the product is small in size, large in torque, short in response time, wide in linear range, small in torque return, and high-quality magnetic powder, resistant to wear and tear ageing.

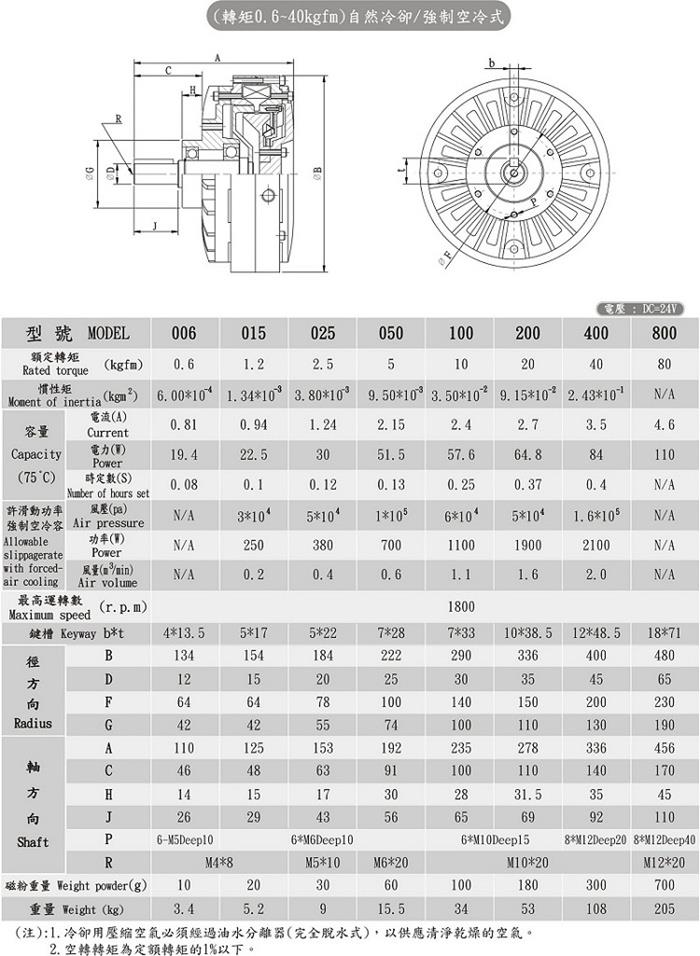

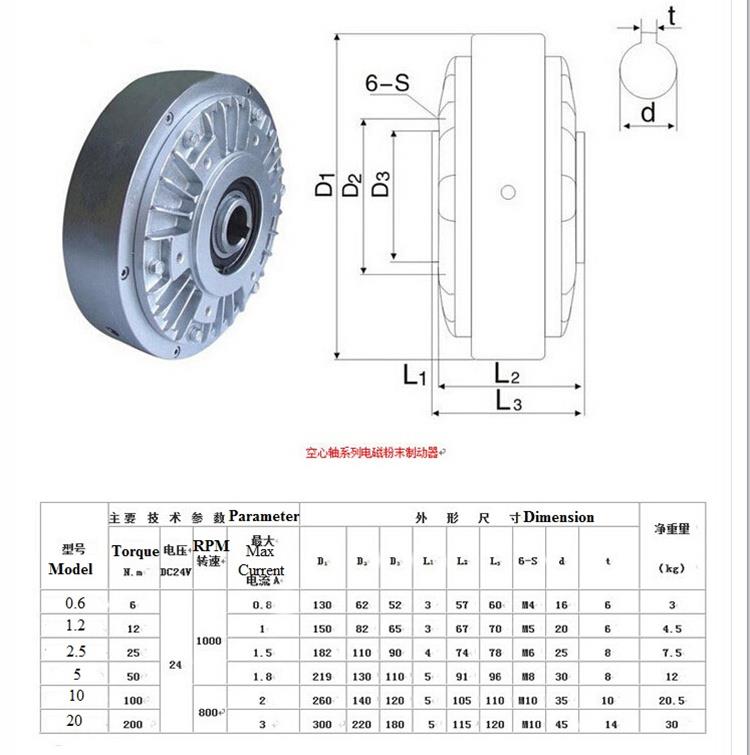

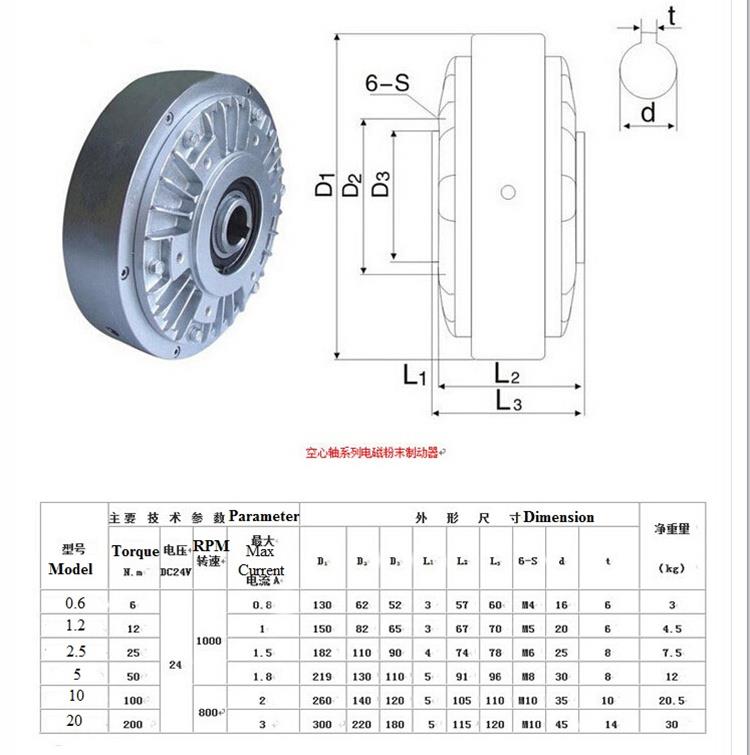

PRE-B Single Shaft Magnetic Powder Brake

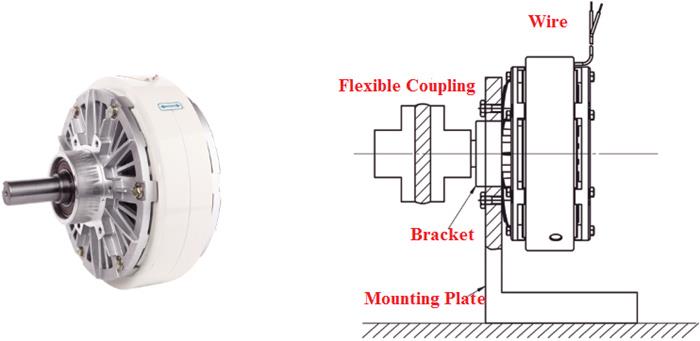

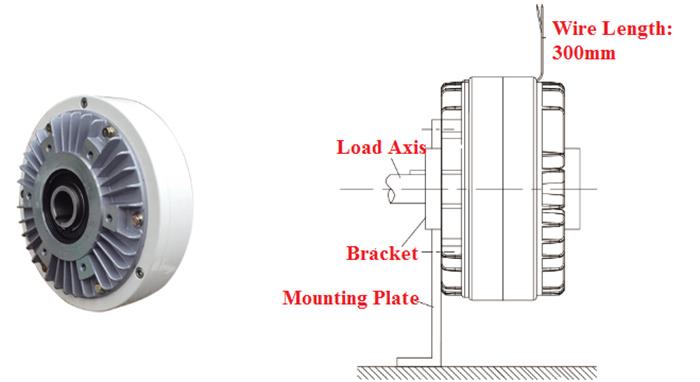

PRE-B1 Hollow Shaft Shell Rotating Magnetic Powder Brake

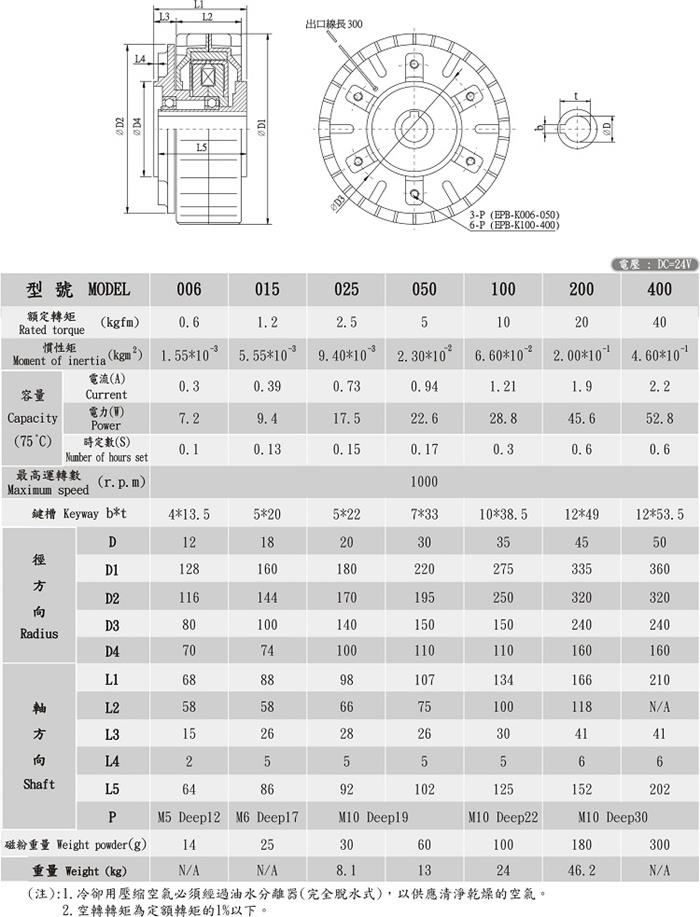

PRE-B2 Hollow Shaft Inner Shell Rotating Magnetic Powder Brake

The temperature exceeds the same old for the duration of the usage of the magnetic powder brake, the purpose of the hot and the restore technique

A magnetic powder brake is a mechanical detail that forestalls or decelerates shifting factors in a machine. normally known as brakes, brakes. magnetic powder brakes can also have a few troubles after using for a period of time, so we need to often preserve the magnetic powder brakes to ensure that the device can characteristic generally in manufacturing.

The motives for the temperature exceeding the usual at some stage in using the magnetic powder brake, the motive of the new and the repair method are as follows:

1. while a short circuit or brief circuit occurs inside the winding, test the winding and do segment safety;

2. while the bearing is poorly lubricated and is stuck, it's miles vital to easy the bearing and upload immoderate temperature grease or update the bearing;

Three. when the fabric is obese and the linkage shaft curler is overloaded, it's far important to reduce the load and add oil lubrication to the moving mechanism;

4. while the solving screw stress is choppy, whilst the brake is biased, the pressure wants to be re-tightened to be even.

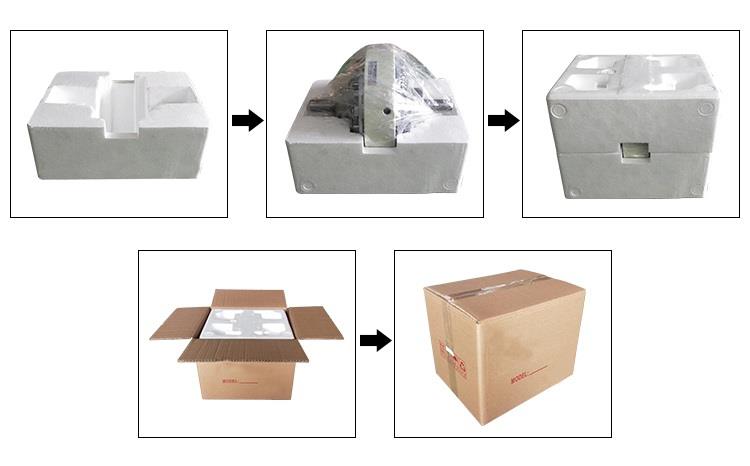

Packing

Order Details

Item Name | Magnetic Particle Brakes/ Magnetic Powder Brake |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Weight | According to different models |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: magnetic particle brake, China, manufacturers, suppliers, factory, quotation, pricelist, buy