Mechanical Clutches

Introduction Magnetic Powder Clutch The magnetic powder brake is an excellent automatic control component, which is a combination of a transmission unit and a driven unit. It uses magnetic powder as the working medium and uses the excitation current as the control means to achieve the purpose of...

Introduction Magnetic Powder Clutch

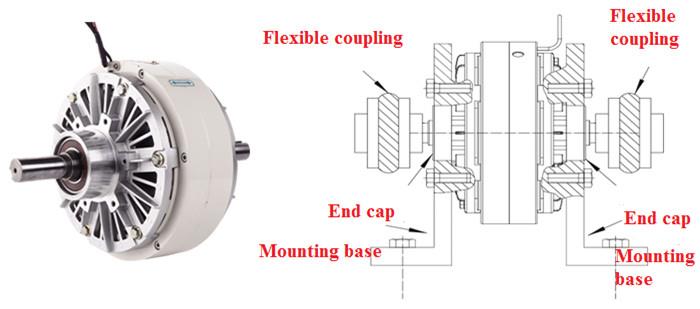

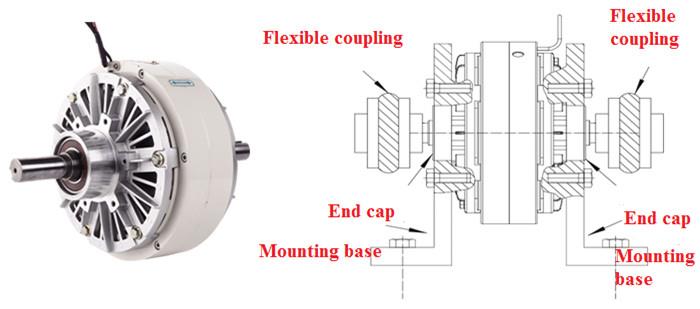

The magnetic powder brake is an excellent automatic control component, which is a combination of a transmission unit and a driven unit. It uses magnetic powder as the working medium and uses the excitation current as the control means to achieve the purpose of controlling braking or transmitting torque. Its output torque has a good linear relationship with the excitation current, and has the advantages of fast response speed and simple structure, so it is suitable for wire, cable, printing, packaging, textile, rubber leather, metal foil strip processing, paper making and paper processing. Etc. In the automatic tension control system for the take-up device. Working principle of magnetic powder brake: Magnetic powder brake mainly consists of brake frame, brake parts and control device. Some brakes are also equipped with automatic adjustment device for brake gap. In order to reduce braking torque and structural size, brakes are usually installed in equipment. On the high-speed shaft, brakes and brakes are used to stop and decelerate mechanical moving parts and mechanical parts.

Classification of magnetic powder clutch

1. Dual-axis magnetic powder clutch

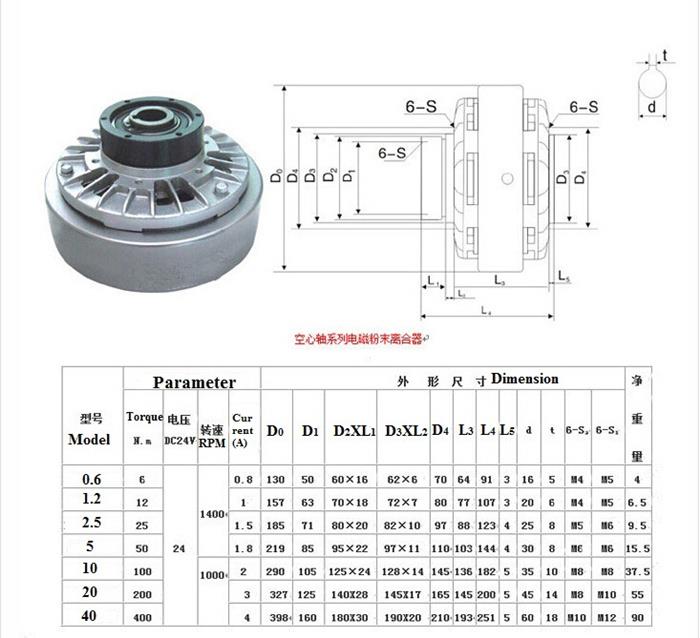

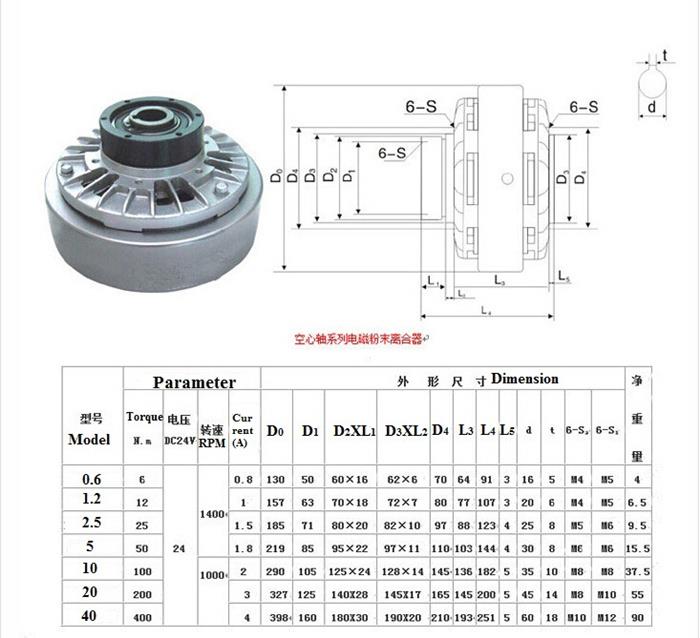

2. Hollow shaft magnetic powder clutch

Magnetic powder brake control matters:

1. Operate the magnetic powder clutch with a regular door diameter (using the high-speed torsion side as the input side). Assuming that the layout of the board is not required to be output to the axis, please be sure to operate with a value of 000R/MIN or more. If the input shaft and the output shaft are reversed, it will be dull and self-idling, and the magnetic powder will be stirred, which will greatly shorten the operating life of the magnetic powder clutch.

2, please pay attention to moisture. If the magnetic powder is damp, it will not become strong, so it is necessary to create it yourself. Do not let oil or water invade the inside. Especially when it is placed in the gearbox, the oil will penetrate into the inside through the shaft, so it should be completely sealed with a film.

3. Please pay attention to the temperature inside. The maximum temperature inside the intermittent operation is 90 degrees or less during operation. When the value is exceeded, the self-sufficiency will be greatly increased. Be sure to use the above-mentioned border temperature as a standard, and be sure to link it within the approved sliding work rate.

The magnetic powder clutch is formed by the transmission unit (input shaft) and the driven unit (output shaft). The space between the two sets of cells is filled with granular magnetic powder (volume perhaps 40 microns). When the magnetic coil is not conductive, the torque will not be transmitted from the transmission shaft to the driven shaft. However, if the coil is electromagnetically energized, the magnetic powder will be emitted due to the magnetic dyeing of the magnetic force, and the phenomenon of igniting and softening will occur. Communicate the torque. The principle of the magnetic powder brake is in communication with the magnetic powder clutch, but the transmission unit is turned into a fixed unit.

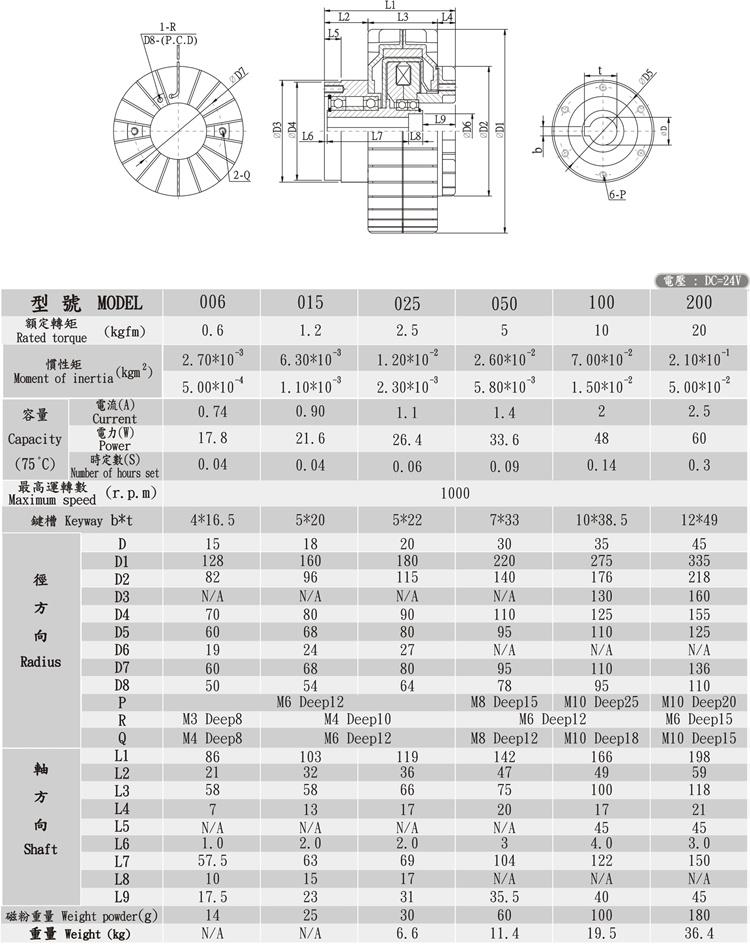

Magnetic powder clutch selection

● The selection of the magnetic powder clutch is generally selected based on the maximum torque required for spreading, and at the same time, the guaranteed actual slip power is less than the promised slip power of the magnetic powder clutch.

The total formula is as follows:

Realistic slip power P=2×3.1 four×M×n/60=F·V (unit: W)

Where: M ----- realistic duty torque (N·m) F ----- tension (N)

n ----- slip speed (r/min) V ----- line rate (m/s)

● In the case of no shifting mechanism, the product of the maximum tension required to wind the material and the maximum winding radius should be less than the rated torque of the magnetic powder brake. In addition, the resolution of the magnetic powder clutch is also related to the position of the position: under the premise of the slip power, the magnetic powder clutch is placed at the high speed level, then the smaller size clutch may be decided, and the volume and cost of the clutch will take off accordingly. When the small-sized magnetic powder clutch can not be kissed, and the larger magnetic powder clutch is needed, it should be placed in the middle or the rear of the transmission head structure to increase the duty torque and increase the slip speed.

●The magnetic powder clutch is at the timing of the heat dissipation condition 1 and its slip power is 1 fixed value. Therefore, the actual duty torque and the rotational speed may complement each other. When the slip speed is increased, the allowable torque will take off accordingly, but the maximum speed may not be taken. Higher than its permitted speed.

Example: FZ100 magnetic powder brake, its rated torque M=100N.m, slip power P=7KW

Then the rated speed n=9550*P/M=9550*7/100=66 八.5r/min

If the actual slip speed is n=1500r/min (9550 is a constant coefficient)

The allowable torque should be M=9550*P/n=9550*7/1500=four 4.6N.m

(where: 9550 is a constant coefficient)

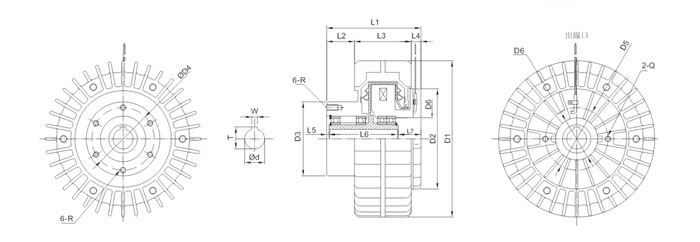

PRE-A Double Shaft Magnetic Powder Clutch

PRE-A1 Hollow Shaft Shell Rotating Magnetic Powder Clutch

PRE-A2 Hollow Shaft Inner Shell Rotating Magnetic Powder Clutch

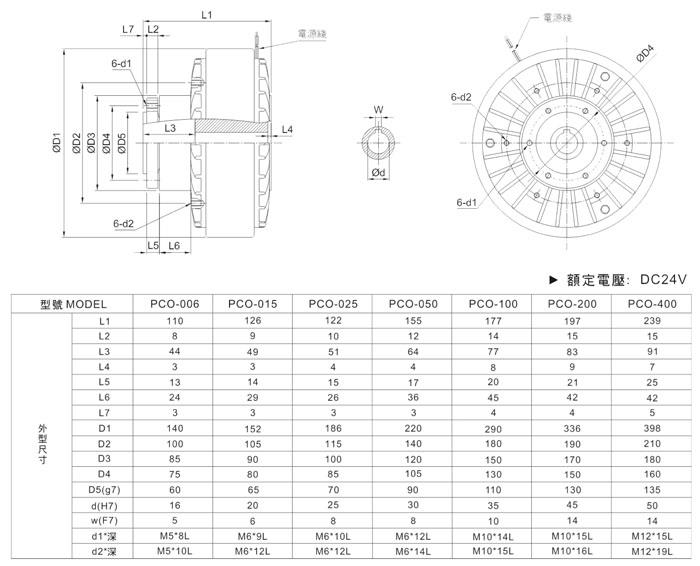

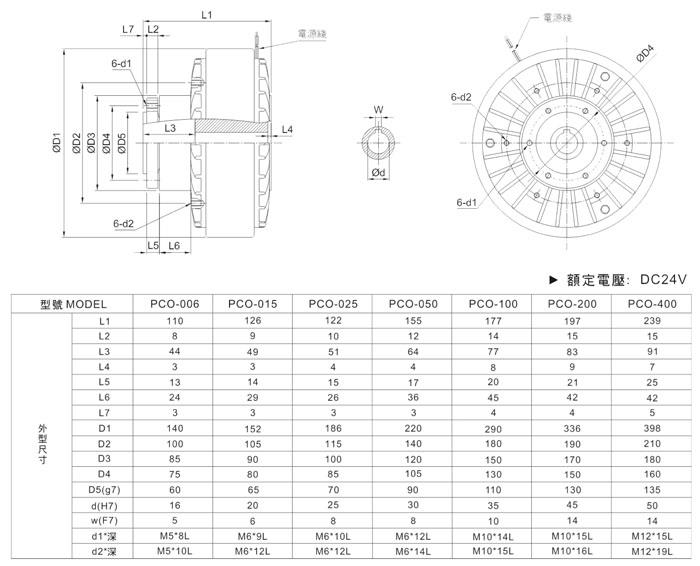

POC rotating magnetic powder clutch

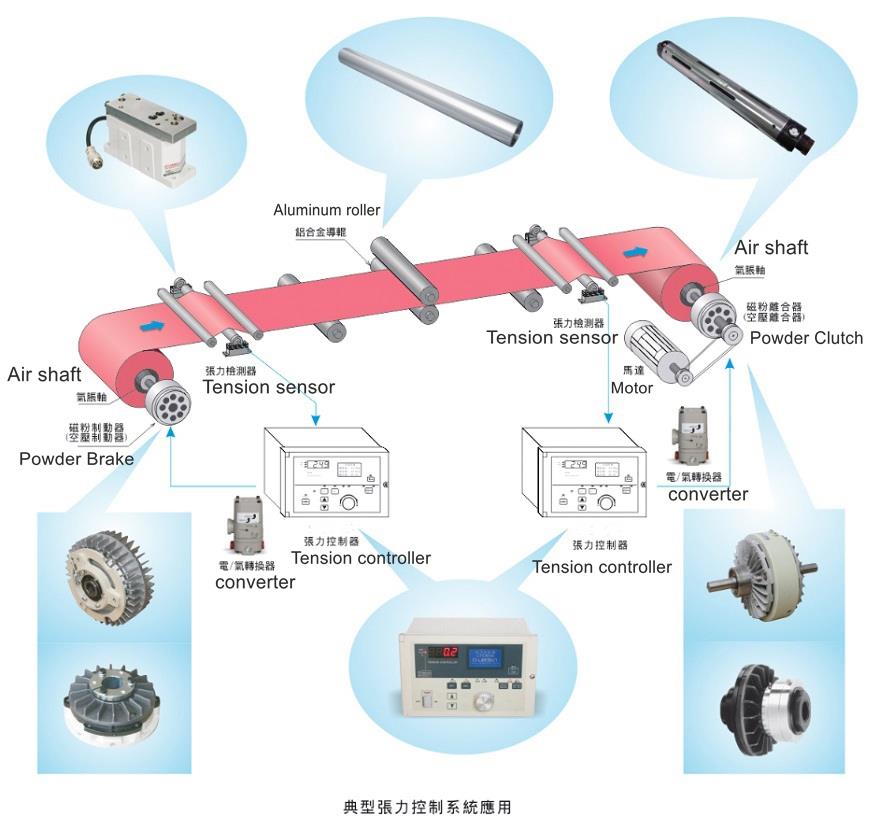

The Schematic Diagram of powder clutch,tension control, web guide system and other parts on equipment.

Magnetic powder clutch, magnetic powder brake product commonality

●The excitation current is linearly related to the torque

The magnetic powder clutch and the magnetic powder brake follow the electromagnetic principle and use the magnetic powder to transmit the torque, and the transmitted torque is basically linearly related to the exciting current. Therefore, only by changing the magnitude of the exciting current, the beam torque can be easily used. Under normal conditions, the excitation current is inversely proportional to the torque it conveys over an additional torque range of 5% to 100%.

● Stubborn slip torque

When the excitation current is understood to be connected, the transmitted torque is not affected by the differential speed (slip speed) between the transmission member and the driven member, that is, the static torque and the energy moment are not different. It is thus possible to stubbornly convey a constant torque. If the commonality is applied to the tension tube bundle, the user can adjust the excitation current to accurately control the bundle and transmit the required torque, thereby cumbersome and usefully reaching the tube bundle tension tension.

●Magnetic powder clutch use range

Due to the above commonality of magnetic powder clutches and brakes, it has been widely used in unwinding and winding tension tube bundles used in papermaking, printing, plastics, rubber, textile, printing and dyeing, wire and cable, metallurgy and other related coiling processing industries. Other magnetic powder clutches can also be used for buffer starting, over carrier, speed regulation, etc. Magnetic powder brakes are also frequently used for dynamometer loading and braking of the head.

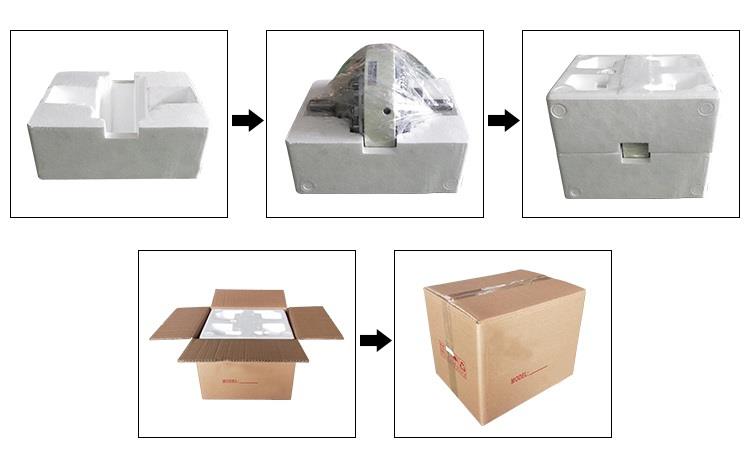

Packing

Order Details

Item Name | Magnetic Powder Clutch |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Weight | According to different models |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: mechanical clutches, China, manufacturers, suppliers, factory, quotation, pricelist, buy