Metal Bead Rollers

For the belt conveyor loafer, it is specifically used to assist the coal at the conveyor belt and the conveyor belt to ensure the stable operation of the conveyor belt. if the selected roller kind and spacing are unreasonable, it's going to immediately have an effect on the entire belt...

For the belt conveyor loafer, it is specifically used to assist the coal at the conveyor belt and the conveyor belt to ensure the stable operation of the conveyor belt. if the selected roller kind and spacing are unreasonable, it's going to immediately have an effect on the entire belt conveyor in the course of the operation system, and it isn't always solid to make sure the transportation of coal.

1) flat curler. the parallel loafer, which is usually an extended loafer, is in particular used as a lower idler to guide the conveyor belt of the empty phase. commonly, the lower curler head is stuck within the assist of the body, and the help has 3 slots vi for adjusting the placement of the idler to correct the deviation of the conveyor belt inside the empty section.

2) the higher curler on the groove. the trough pinnacle loafer is commonly a mixture of three brief idlers with groove angles of 30°, 35° and 45°. the usual groove attitude of the higher roller is 35°. normally, the most used one conveyor is the 35° groove curler and the 35° groove forward roller. it's miles commonly used as a heavy obligation curler for conveying coal and the like.

Three) transition roller. within the design technique, for huge conveyors, lengthy distances, conveyor belt tension and critical conveyors, the transition phase have to commonly be set, this is, the place in which the transition rollers are organized. the minimal transition period of the middle line of the head curler to the centerline of the primary set of regular grooved idlers, and the tail transition section ought to be set thus whilst situations allow.

4) buffer curler. for the buffer rollers, a rubber ring shape is normally used, and each set of the grooved curler body consists of three buffer rollers. so that it will reduce the impact load, spring steel can be used to make the roller brackets on each facets. the groove attitude of the cushioning curler has three kinds of 30°, 35° and 45°. when the use of a cotton canvas core conveyor belt, only a 35° groove cushioning curler may be used. it's far particularly installed on the loading point of the conveyor to cushion the conveyor belt.

5) self-aligning roller. the software model has many bureaucracy, and may be divided into kinds: an upward adjustment heart roller and a downward adjustment heart curler consistent with the use form; according to the use impact, it may be divided into sorts: a friction centering curler and a pile shape adjusting roller. the characteristic of the self-aligning curler is especially used to robotically correct the excessive deviation of the conveyor belt at some point of operation to save you the conveyor belt from being snaked and to ensure the solid operation of the conveyor.

6) spiral curler. it's miles in particular used to smooth the coal adhered at the bearing surface of the conveyor belt. its feature is the same as that of the purifier. generally, the set of lower rollers closest to the top drum of the conveyor may be designed as a spiral curler.

Roller Diameter mm | Roller length mm | Bearing | roller shell thick mm |

76 | 160-950 | 6204 | 3.0-4.5mm |

89 | 160-950 | 6204 | |

102 | 160-950 | 6204 | |

108 | 250-1600 | 6305 | |

114 | 160-1753 | 6305 | |

121 | 160-1753 | 6305 | |

127 | 160-1753 | 6305 | |

133 | 250-2500 | 6305 | |

152 | 160-2500 | 6305 6306 | |

159 | 315-2800 | 6305 6306 | |

178 | 315-2800 | 6305 6306 | |

219 | 315-2800 | 6305 6306 | |

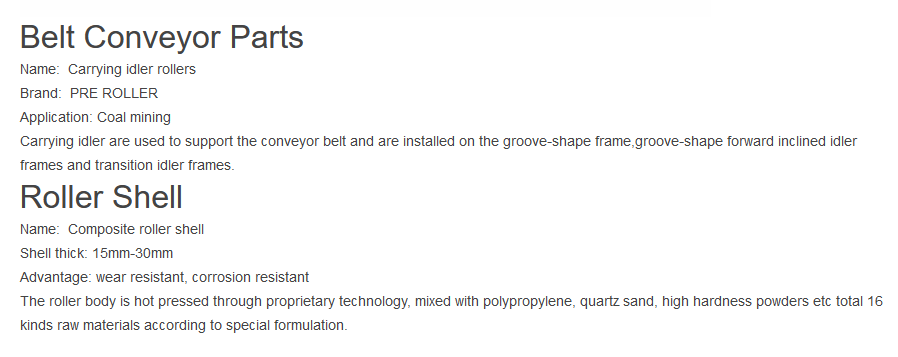

Roller Seals

Seal type: DTII type seall, labyrinth seals

![S}GA4C8B]{$VY1NZYZDUG~E](png/201910180953149780683.png)

Composite rollers structure features

Composite roller is made of composite shell, composite material bearing seat, metal shaft, bearings and DTII type seals.

Packing & Delivery

Order Details

Item Name | Metal Rollers |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients’demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: metal bead rollers, China, manufacturers, suppliers, factory, quotation, pricelist, buy