Metal Forming Bead Rollers

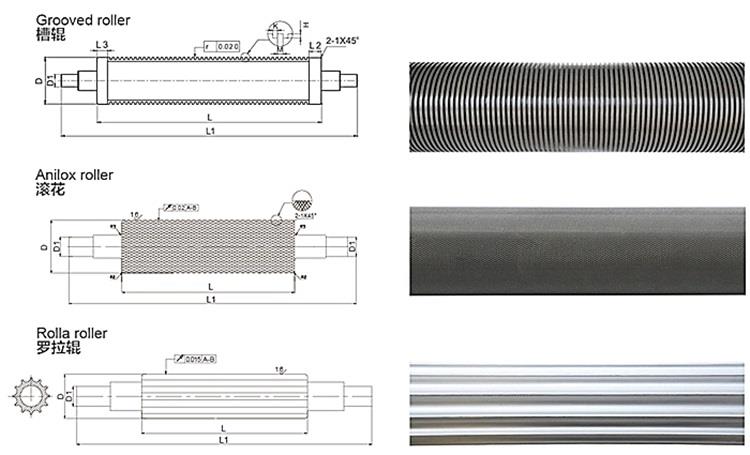

Choose the right aluminum guide roller 1. According to the number of mesh lines of the aluminum guide roller, in order to ensure accurate reproduction of the dots of each tone level of the printing plate, each dot on the aluminum guide roller must be accurately inked. For this reason, the...

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

Choose the right aluminum guide roller

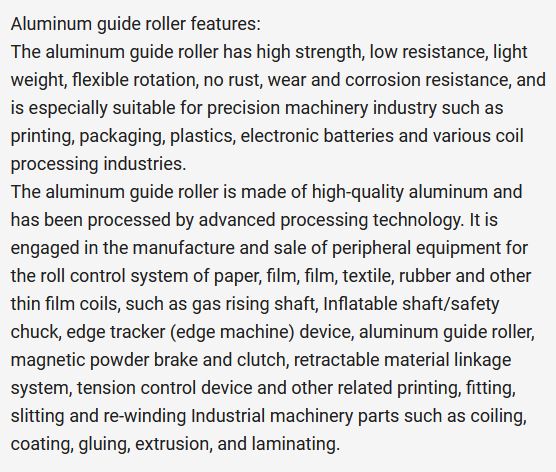

1. According to the number of mesh lines of the aluminum guide roller, in order to ensure accurate reproduction of the dots of each tone level of the printing plate, each dot on the aluminum guide roller must be accurately inked. For this reason, the opening area of the aluminum guide roller should be smaller than the area of the dot, so that one or several ink holes can be inked, so that the dot is not trapped in the mesh, and the printed dot is enlarged.

2, high-precision aluminum roller according to the structure of the text, for the same high-precision aluminum roller mesh engraving process, the higher the number of mesh lines, the less the amount of ink, suitable for printing dots and small text; high-precision aluminum roller and cable The lower the number, the more the amount of ink is transferred, which is more suitable for printing large-area color blocks and bold characters.

3. Select the reticulated aluminum guide roller according to the degree of wear of the different aluminum rolls: when the volume of the inking hole of the anilox roll is reduced by half, it should be replaced with a new one.

4. The aluminum roller is selected according to the substrate. When the surface of the substrate is rough and the amount of ink transferred is large, the aluminum roller is required to use an anilox roller with a small number of screen lines; on the contrary, the substrate with a smooth printing surface needs to use a large number of screen wires. Anilox roller with a small amount of ink transfer.

5. Select aluminum guide according to different inking units.

Application

Order Details

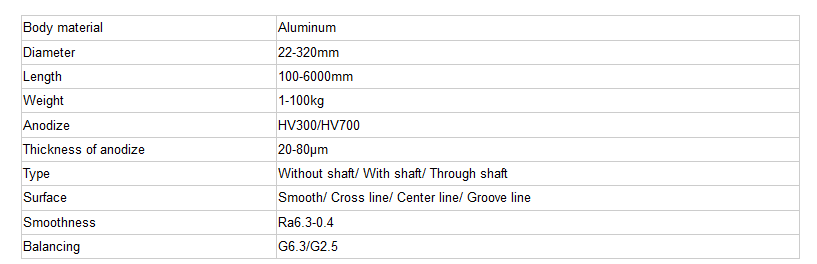

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: metal forming bead rollers, China, manufacturers, suppliers, factory, quotation, pricelist, buy