Metal Rolling

The aluminum guide roller is likewise known as the aluminum alloy manual roller. it is fabricated from awesome aluminum alloy material, and has diverse specifications of the tube through the mildew. it has a strengthened rib structure and excessive electricity. and the usage of precision system...

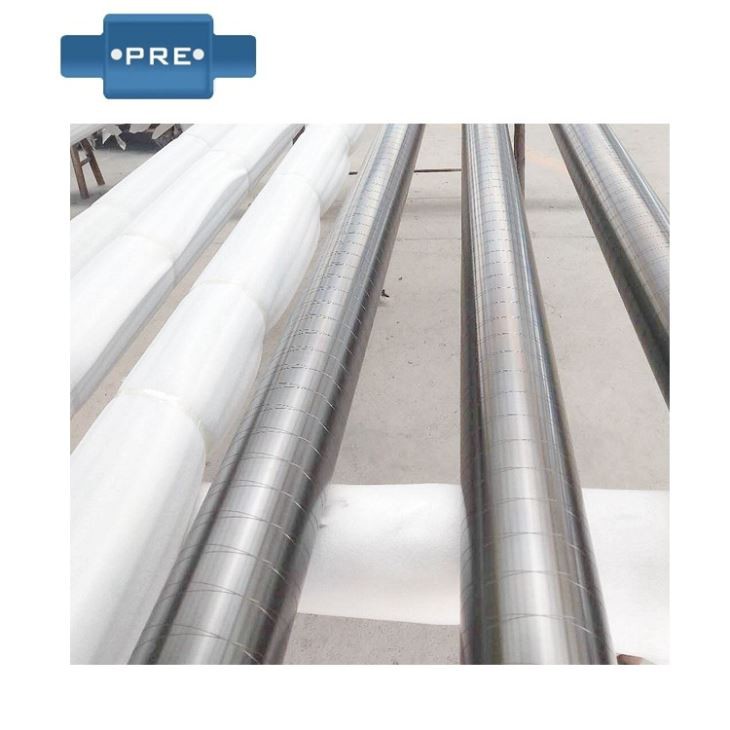

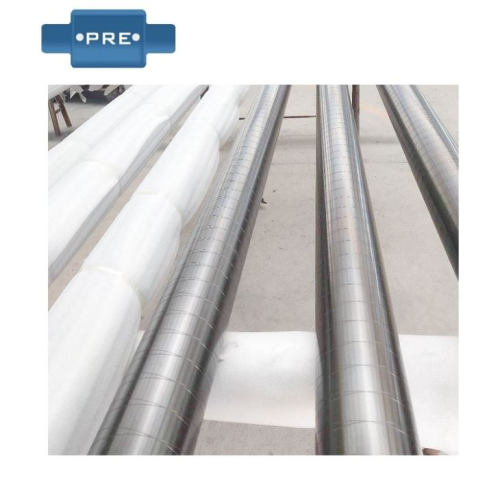

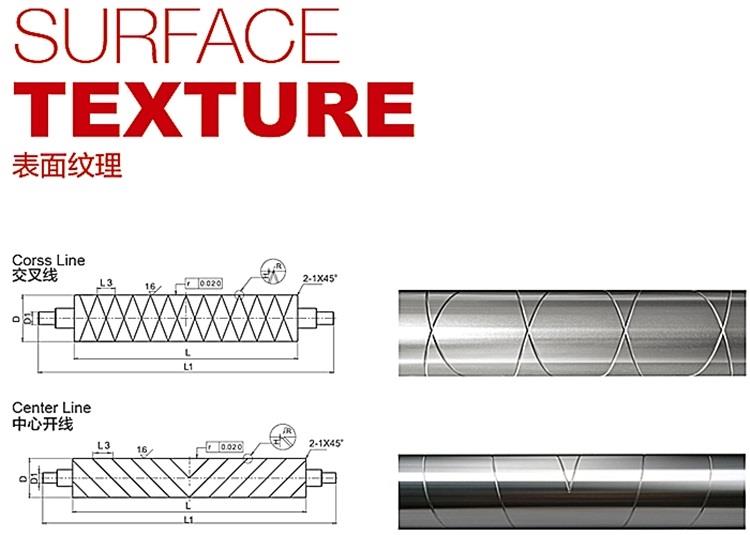

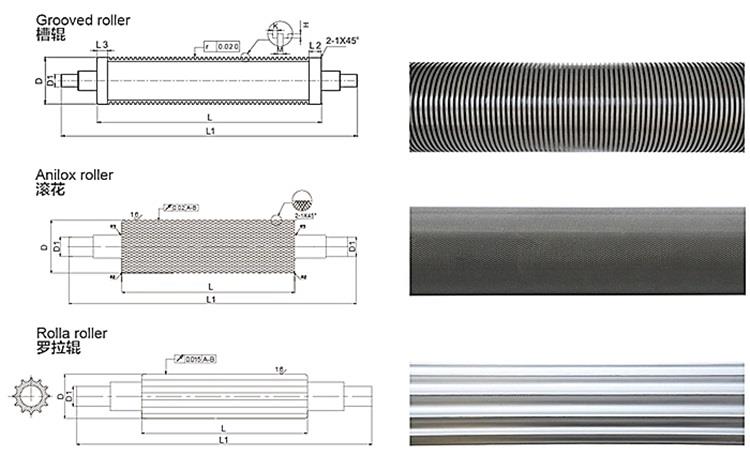

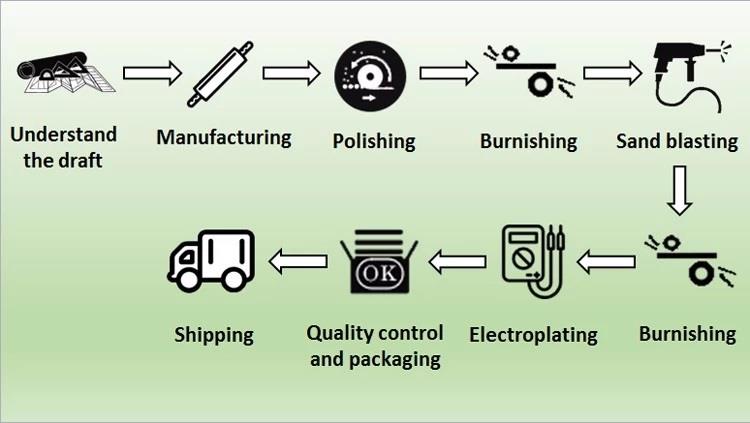

The aluminum guide roller is likewise known as the aluminum alloy manual roller. it is fabricated from awesome aluminum alloy material, and has diverse specifications of the tube through the mildew. it has a strengthened rib structure and excessive electricity. and the usage of precision system and unique tools for floor completing, the surface is easy, the coaxiality reaches 0.02mm, the whole axis is corrected within 2g by laptop balance correction, the unique era of the shaft give up and the imported bearings can be without problems operated underneath high velocity. works freely. in line with the distinctive desires of the enterprise, the surface can also be in particular treated: sand blasting, netting and special hardening treatment, in order that it has suitable scratch resistance and wear resistance.

The customizable aluminum guide curler has the blessings of high electricity, low resistance, light weight, flexible rotation, put on resistance and corrosion resistance, and bright floor. it is specially appropriate for printing, packaging, movie, paper, medicine, plastic, electronic battery, and so forth. precision machinery industry and various coil processing industries.

Aluminum guide rolls are also known as aluminum alloy guide rolls, which are selected by high quality aluminum alloy materials (6063 - T5), molds are tubular (from 30 mm to 220 mm diameter) in various sizes, with steel structure, high strength .

The aluminum guide roller uses complex surface treatment equipment and special tools, the surface is smooth, the coaxiality is 0.02 mm, the whole shaft is processed by computer balance correction at 2 g, the special process of the shaft end, with the imported bearings, high-speed operation, easy operation . According to different industry needs, the surface can be specially treated: sand blasting, mesh, PTFE and special hardening treatment HV700, which makes it have good scratch resistance and wear resistance.

Application

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

Application

Order Details

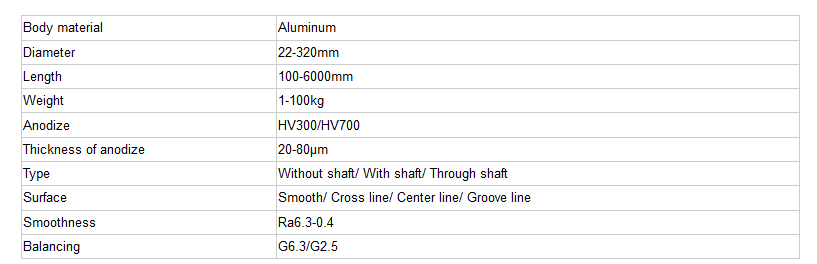

Item Name | Aluminum idler roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: metal rolling, China, manufacturers, suppliers, factory, quotation, pricelist, buy