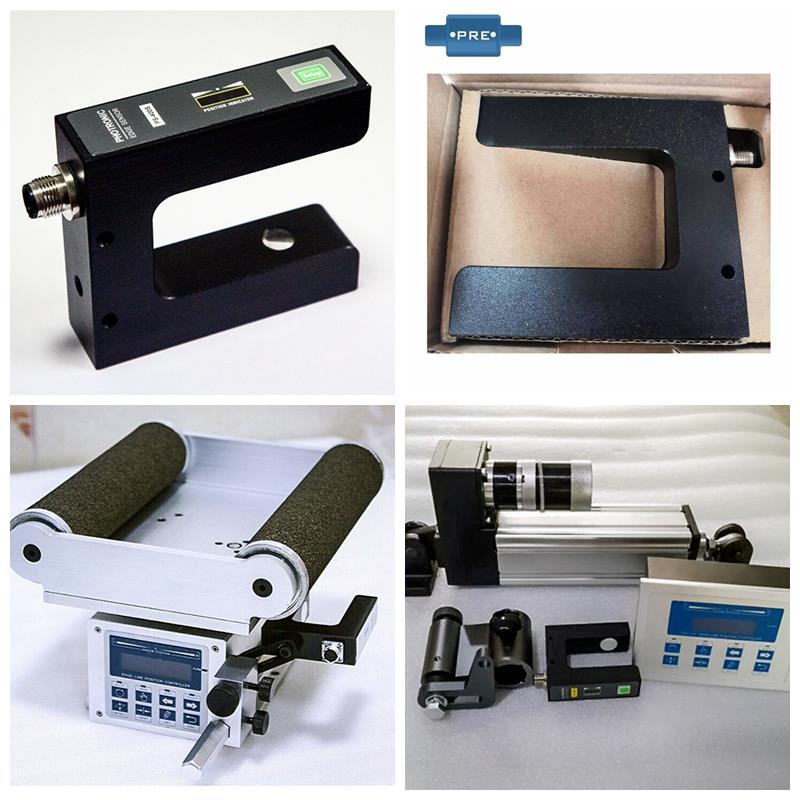

Photoelectric Guide Sensor

The photoelectric guide sensor adopts the coaxial reflection principle to output a two-way symmetric analog voltage signal, and the photoelectric guide sensor can be directly matched with the deviation correction system.

The photoelectric guide sensor adopts the coaxial reflection principle to output a two-way symmetric analog voltage signal, and the photoelectric guide sensor can be directly matched with the deviation correction system. Photoelectric sensors are mainly used for heel and heel operations of coil materials, and can be adapted to transparent or opaque materials. Photoelectric correction sensor is widely used in rewinding, slitting, compounding, coating, etc. for retracting tracking and rewinding tracking or intermediate position tracking.

Features

1: Widely used

2: Accurate Edge Detection

3: For perfect Roll Generation

4: Easy Installation

Application

The photoelectric sensor has the characteristics of high precision, fast response, non-contact measurement and simple structure, and is widely used in detection and control. Although the form of photoelectric sensors is flexible and diverse, there are generally some technical problems that require further elimination. When many users detect an object, the sensor does not display a signal. The average person often thinks that the photoelectric sensor is broken. This is not the case. Let's analyze it for everyone.

The first thing to consider is the problem of wiring or configuration. For the through-beam type photoelectric sensor, it must be used in combination by the light projecting part and the light receiving part, and both ends need to supply power; and the retroreflective type must be used by the sensor probe and the retroreflective sheeting together; at the same time, the user must provide a stable power supply to the sensor, if For DC power supply, the positive and negative poles must be confirmed. If the positive and negative terminals are connected incorrectly, the output signal will not be generated.

The above-mentioned cause analysis is a consideration of the photoelectric sensor itself. We also need to consider the problem of detecting the position of the object. If the detected object is not in the detection area, such detection is futile. The object to be detected must be within the area that the sensor can detect, that is, within the range that the photoelectric can be perceived. Secondly, it is necessary to consider whether there is a problem of alignment of the optical axis of the sensor. The projecting portion of the projecting type and the optical axis of the light receiving portion must be aligned, and the corresponding retroreflective probe portion and the optical axis of the reflector must be aligned.

Also consider the criteria for detecting whether an object meets the standard or minimum detection object. The detection object cannot be smaller than the standard of the smallest detection object, so as to avoid the reflection type and the reflection type cannot detect the transparent object well. The color of the detected object is required, and the darker the color, the closer the detection distance is.

If all of the above are excluded, the next step is to check for interference from environmental factors. If the light intensity cannot exceed the rated range; if there is dust in the field environment, we need to clean the surface of the photoelectric sensor probe regularly; or multiple sensors are closely installed to interfere with each other; and one of the most influential is electrical interference, if there is For high-power equipment, there must be corresponding anti-interference measures when generating interference.

Order Details

Item Name | PS-400S Photoelectric Sensor |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 1-2 days after receiving the deposit |

Calculated Packing Size | 15cm*10cm*10cm,1kg/pc |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: photoelectric guide sensor, China, manufacturers, suppliers, factory, quotation, pricelist, buy