Powder Brake Systems

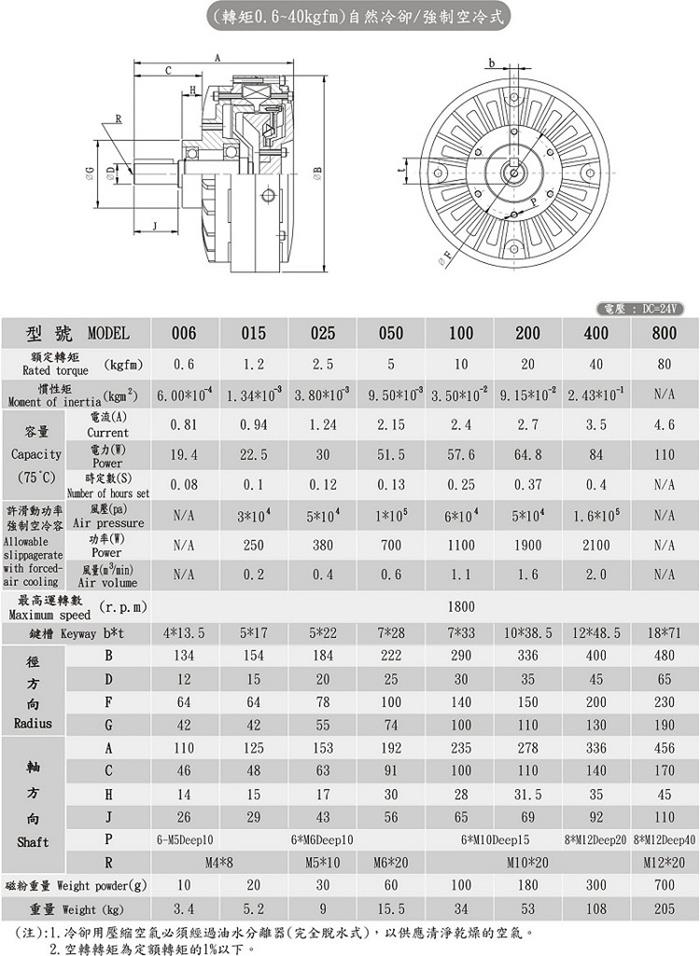

The conventional magnetic powder brake uses DC 24V as the excitation current, so it is very safe and direct contact with the hand does not affect it. Although it uses less power, it can transmit a large amount of torque and is easy to implement remote control. In addition, the magnetic powder...

The conventional magnetic powder brake uses DC 24V as the excitation current, so it is very safe and direct contact with the hand does not affect it. Although it uses less power, it can transmit a large amount of torque and is easy to implement remote control. In addition, the magnetic powder brake does not allow the use of a half-wave rectified power supply.

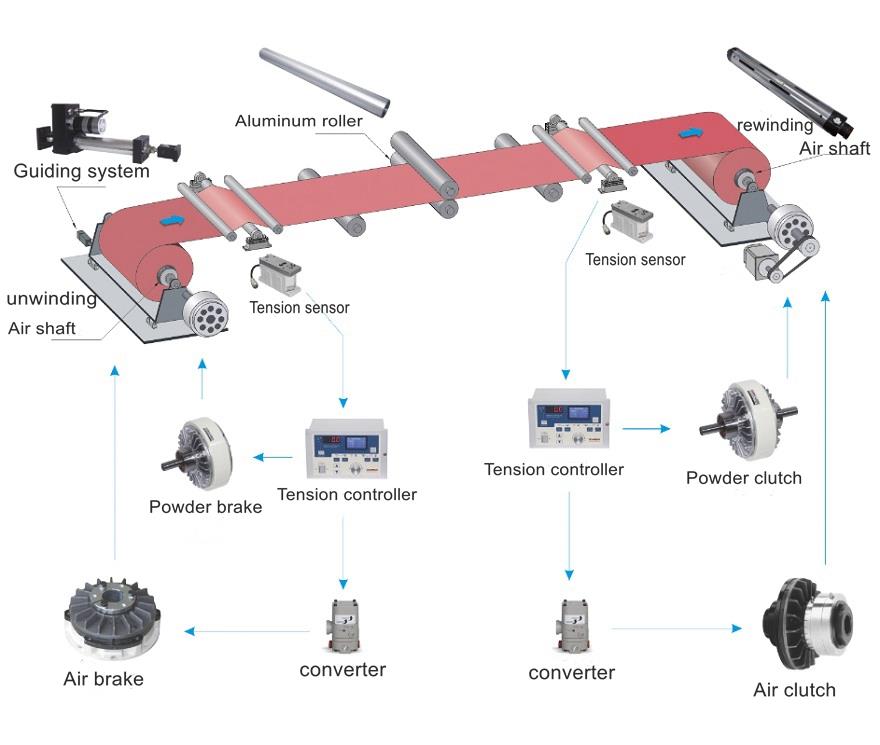

Magnetic powder brakes are widely used in some high-speed stranding machines, wire cutting machines, high-speed extruders, tandem production lines, shaftless pay-off racks, extrusion lines, twisting machines, single stranding machines, insulation production lines, etc., in modern industry. It is very common in mechanical equipment, especially in light industrial equipment.

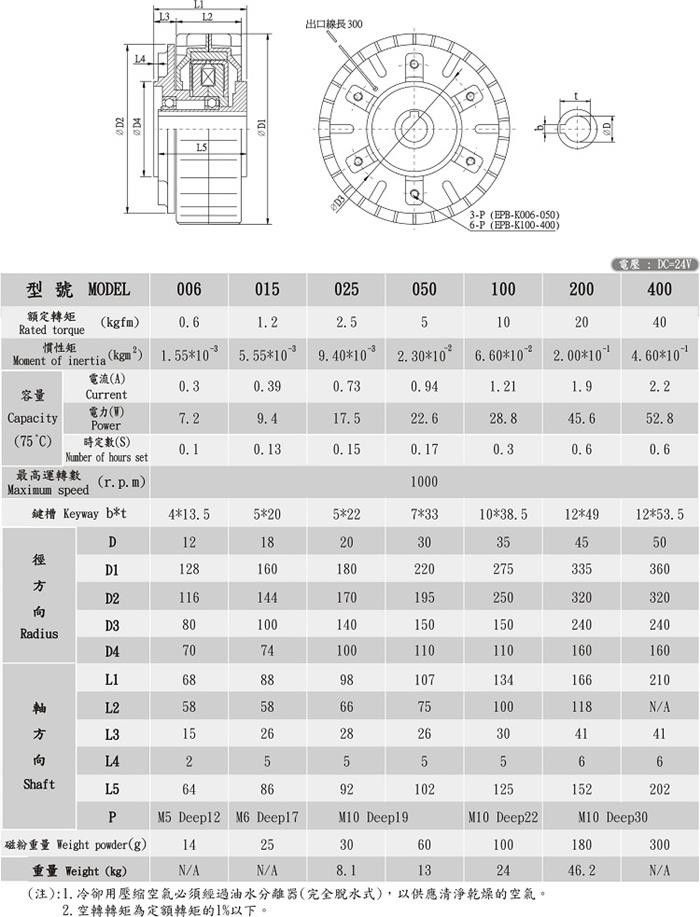

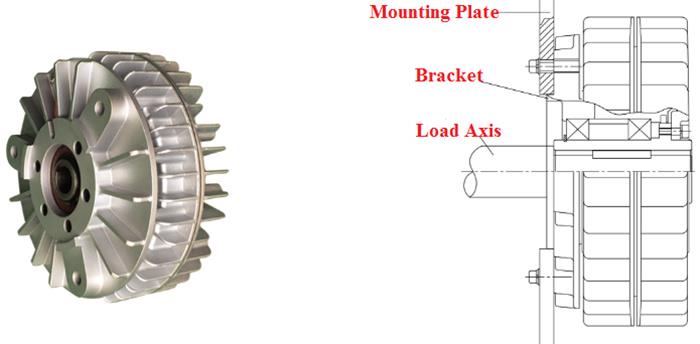

PRE-B Single Shaft Magnetic Powder Brake

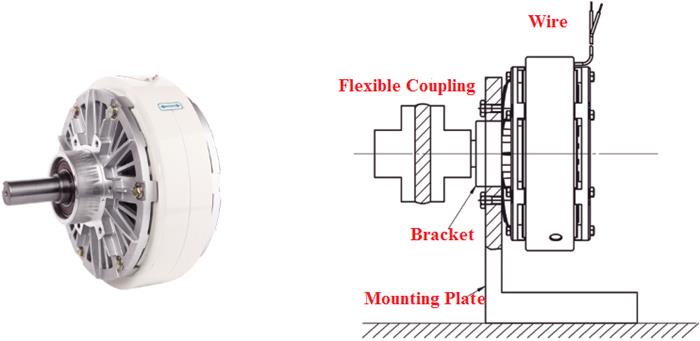

Single output magnetic powder brake, housing rotary brake. How to install the main accessories such as fixing screws, elastic shafts, mounting plates, reels, safety chucks, etc. According to the actual conditions of the space and conditions of the mechanical equipment, how to install it. When the space is insufficient or the conditions are not available, you should consult the magnetic powder brake manufacturer immediately and request technical support. If a larger magnetic powder brake or brake type is used (the weight is 4KG to 100KG), it is not necessary to check whether it is fixed or not, and the fasteners and mounting brackets are fixed.

Installation Precautions:

1. All the inlays are used. Please do not hit and apply excessive force during assembly.

2. Use the magnetic powder clutch brake in the standard installation state with the high-speed rotary end as the input. The shaft of the clutch and brake must be installed horizontally.

3. Be sure to use a flexible coupling to connect the input of the clutch.

4. Please pay attention to the belt tension when connecting the pulley. Please do not add the initial tension other than the rated one.

5. Please ensure that the heat sink of the mounting plate is more than 350 square CM.

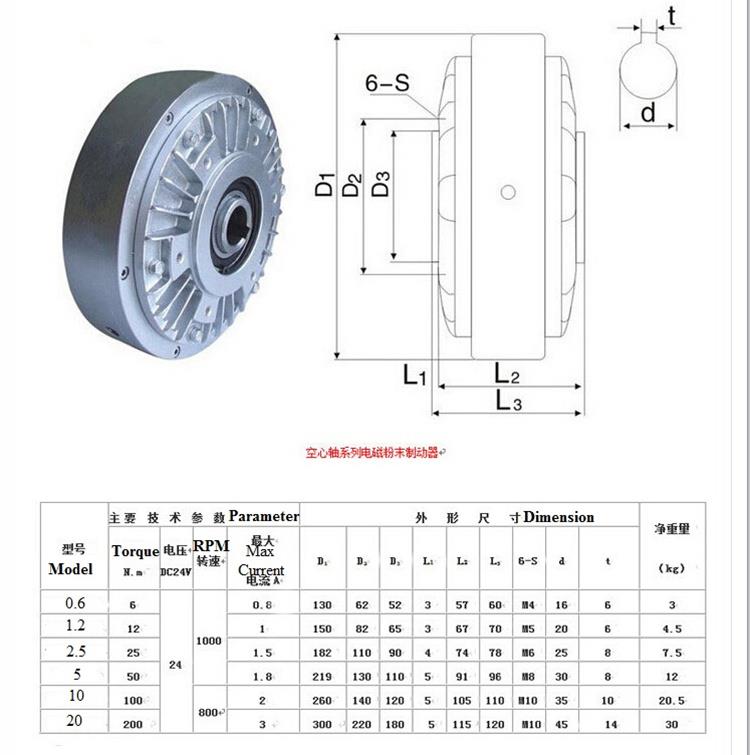

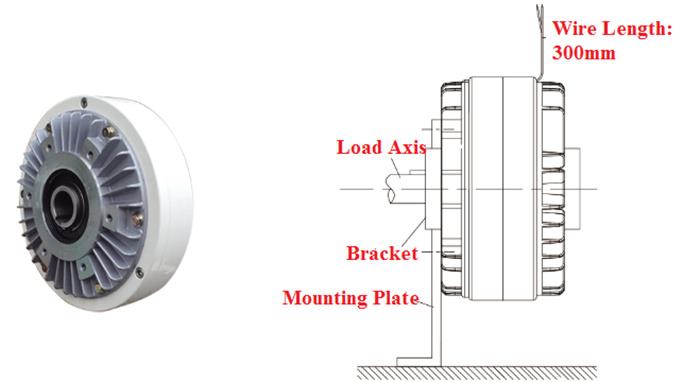

PRE-B1 Hollow Shaft Shell Rotating Magnetic Powder Brake

PRE-B2 Hollow Shaft Inner Shell Rotating Magnetic Powder Brake

Advantages and installation of hollow shaft magnetic powder brake

The main advantages of hollow shaft magnetic powder brakes:

1. During the brake engagement process, it is easy to make the torque increase smooth, so the brake has good joint smoothing performance.

2, can slide the work for a long time.

3. No adjustment is needed during use.

Hollow shaft magnetic powder brake installation precautions:

a. Pay great attention to avoid installation deviations during installation

(1) The upper pressing gland should be carried out after the coupling is aligned. The bolts should be evenly supported to prevent the end face of the gland from being skewed. Check the points with a feeler gauge. The error is not more than 0.05 mm.

(2) Check the fit clearance (ie, concentricity) between the gland and the outer diameter of the shaft or bushing. The circumference should be uniform. Check the tolerance of each point with a feeler gauge to be no more than 0.01 mm.

b. The amount of spring compression should be carried out according to the regulations. It is not allowed to be too large or too small, and the required error is 2.00 mm. Over the assembly, the end face is pressed and the other end face is worn. Too small will cause insufficient specific pressure and will not seal.

c. After the moving ring is installed, it can be flexibly moved on the shaft. After the moving ring is pressed against the spring, it should be able to spring back automatically.

The hollow shaft magnetic powder brake should be disassembled. Care should be taken when disassembling the mechanical seal. Do not use the hand hammer and the flat shovel to avoid damage to the sealing components. A pair of wire hooks can be made, and the sealing device is pulled out in the direction of self-supporting profit and loss into the gap of the transmission seat. If the scale is not removed, it should be cleaned before disassembly.

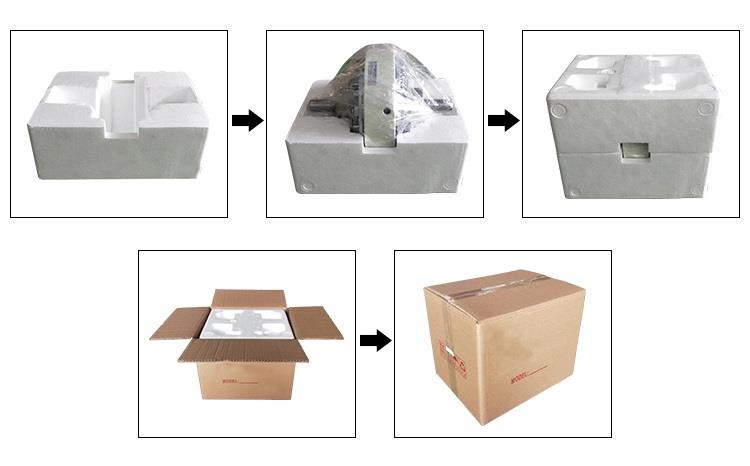

Packing

Order Details

Item Name | Magnetic Powder Brake |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Weight | According to different models |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: powder brake systems, China, manufacturers, suppliers, factory, quotation, pricelist, buy