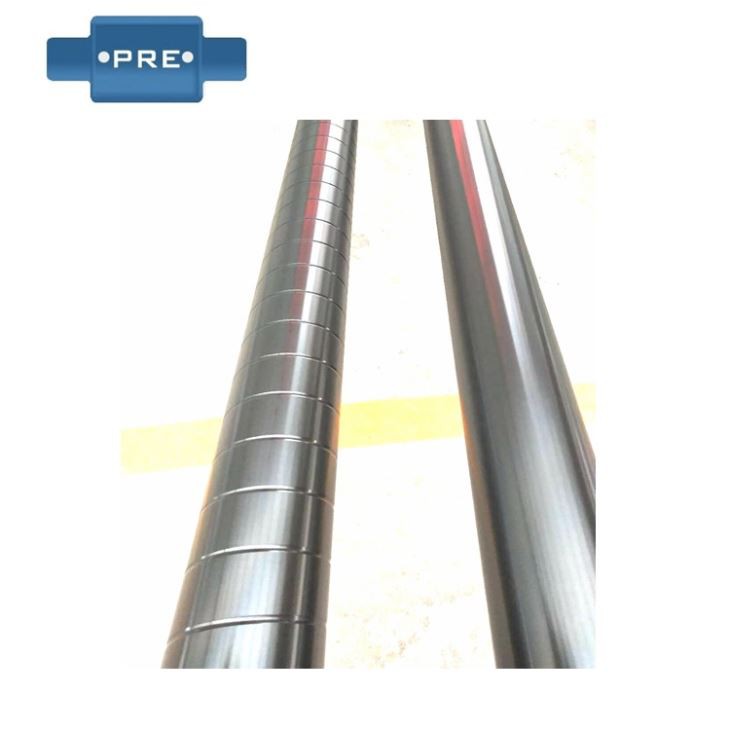

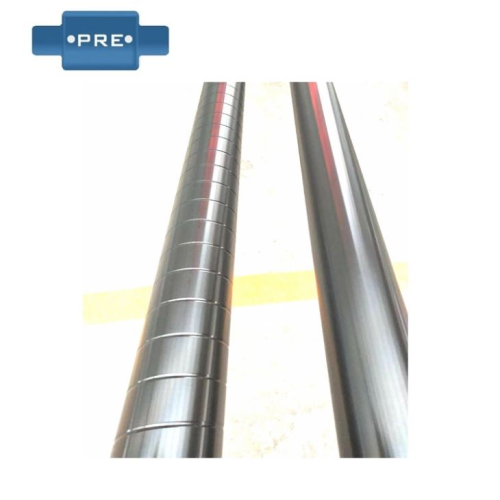

Self-alignment Roller

Aluminum guide rollers mainly focus on the market status (including regional markets), market competition and supply and demand pattern (including regional markets), market size (including regional markets), market prospects (including regional markets), technology development trend analysis,...

Aluminum guide rollers mainly focus on the market status (including regional markets), market competition and supply and demand pattern (including regional markets), market size (including regional markets), market prospects (including regional markets), technology development trend analysis, price analysis, and advancement. Scientific analysis of export analysis, usage and brand share, corporate competitiveness and analysis of major financial data, relevant policies and regulations and environmental analysis, investment strategy, investment risk, risk aversion, and marketing strategy selection.

At present, the aluminum guide rolls commonly used in China have low hardness and short service life, which affects the high-line production efficiency and product qualification rate. Ordinary heat-resistant steel, wear-resistant steel or wear-resistant cast iron rolls have short service life, resulting in rolling mill operating rate. Reduced. Carbide roller has good wear resistance and high temperature stability, good use effect, but high production cost. Cast high speed steel contains a lot of alloy elements such as w, Mo, Cr, v, and has high room temperature hardness. Compared with common materials, aluminum guide rolls have excellent red hardness, 550 ~ 560cc hold above HRC60, high temperature wear resistance. Generally used in the manufacture of hot rolling mill work rolls. However, high speed steel w, Mo price is higher By reducing the amount of w, Mo and increasing the trace elements such as Nb, N, Re, the aluminum guide rolls make the experimental steel grade reach or close to the hardening properties of high-speed steel, and at the same time reduce the cost of steel to a large extent.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

The way to operate the aluminum guide curler

The operation approach of the aluminum guide roller, the precise operation of the aluminum guide curler improves the utilization fee of the scraper and decreases the wear and tear on the anilox curler. from this component, the wall wear is much less, and the network is highly deep. sporting a big part of the fluid in step with day allows the desired coating weight.

Aluminum foil substrates and the quality coating adhesives discussed after the aluminum foil, p.c sheet after warmness, warmness sealant strong aluminum manual rolls are usually measured by way of the warmth seal electricity adhesive layer.

In a sure variety, the aluminum foil of the aluminum guide curler and the percent warmth seal energy are proportional to the paint, but no longer to a degree, in most of the take a look at instances, the coating weight is three, 6 g / cm ^ 2 can meet the heat seal power necessities. if the coating weight is extended, the warmth seal power fee is increased to a sure fee because the coating quantity, the warmth seal electricity curve tends to be balanced, and the strength alternate is small, so it isn't always vital to growth the range of the adhesive layer, and the fee is likewise improved.

Application

Order Details

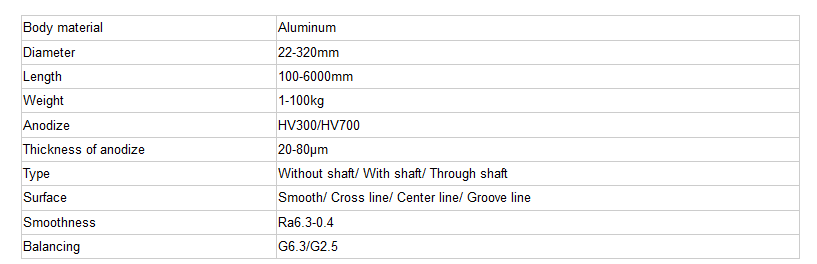

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: self-alignment roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy