Sensors Web

The principle of the photoelectric sensor: the light-emitting element of the emitter emits light and is received by the light-receiving element of the receiver.

Photoelectric sensor main type Reflective type: The light emitting element and the light receiving element are built in one sensor amplifier. Receiving reflected light from the detected object. Transmissive type: The transmitter/receiver is in a separate state. If a detection object is placed between the transmitter/receiver, the light from the transmitter is blocked.

Retro-reflective type: The light-emitting element and the light-receiving element are built in one sensor amplifier. Receiving reflected light from the detected object.

The light of the light-emitting element is reflected by the light-reflecting plate and received by the light-receiving element. If you enter the detection object, it will be blocked.

Narrow beam reflection type: Spot illumination is performed on the detection object, and reflected light from the detection object is received and detected.・Detects small targets.・Detectable mark.・It can be detected from the gap of machinery.・Detection points are visible.

Limited reflection type: A structure that uses an angle between the transmitter and the receiver to detect only the restricted area where the respective optical axes intersect.・The background influence is small.・The distance should be short.・Detects small bumps.

The distance setting type of the photoelectric sensor: the spot is irradiated onto the detection object, and is detected by the difference in angle from the light reflected by the detection object.・Not affected by backgrounds with high reflectance.・Stable detection is possible even if the color of the detected object and the reflectance of the material are different.・High-precision detection of small objects is possible.

Features

1: Widely used

2: Accurate Edge Detection

3: For perfect Roll Generation

4: Easy Installation

Application

The precautions of the Photoelectric sensor when using

What should I do if the photoelectric sensor has a problem in use? How can we reduce the failure of photoelectric sensors? This is a problem that many users will encounter when using photoelectric sensors. How to solve these problems? In fact, paying more attention to the use of photoelectric sensors in daily life can alleviate the occurrence of faults. Note on the use of the sensor.

1 The front end surface of the photoelectric sensor in use must be parallel to the surface of the workpiece or object to be inspected, so that the photoelectric sensor has the highest conversion efficiency.

2 When mounting soldering, the minimum distance between the pin root of the photoelectric sensor and the pad shall not be less than 5mm, otherwise the die may be damaged during soldering. Or cause changes in die performance. The welding time should be less than 4 seconds.

The minimum detectable width of the 3-beam photoelectric sensor is 80% of the width of the photoelectric switch lens.

4 When using inductive loads (such as lamps, motors, etc.), the transient inrush current is large, which may deteriorate or damage the photoelectric sensor of the AC two-wire. In this case, please switch the load through the AC relay.

5 Infrared photoelectric sensor lens can be wiped with lens paper, disabling chemicals such as dilution solvent to avoid permanent damage to the plastic mirror.

6 For the actual requirements of the user's site, under some harsh conditions, such as dusty occasions, the photoelectric sensor produced has increased the sensitivity by 50% to accommodate the long-term use of the photoelectric sensor maintenance cycle. Claim.

7 Photoelectric sensors must be installed in direct sunlight without strong light, because the infrared light in the strong light will affect the normal operation of the receiving tube.

Order Details

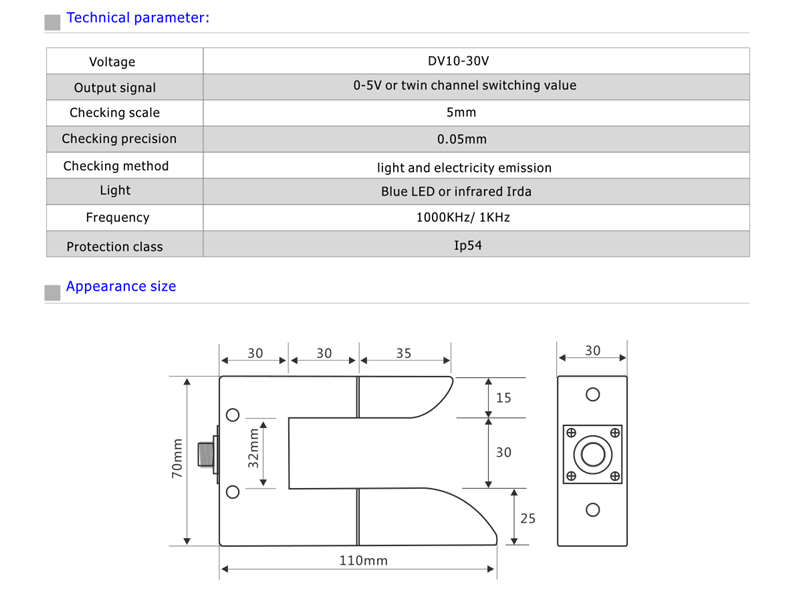

Item Name | PS-400S/500S Photoelectric Sensor |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 1-2 days after receiving the deposit |

Calculated Packing Size | 15cm*10cm*10cm,1kg/pc |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: sensors web, China, manufacturers, suppliers, factory, quotation, pricelist, buy