Through Roller

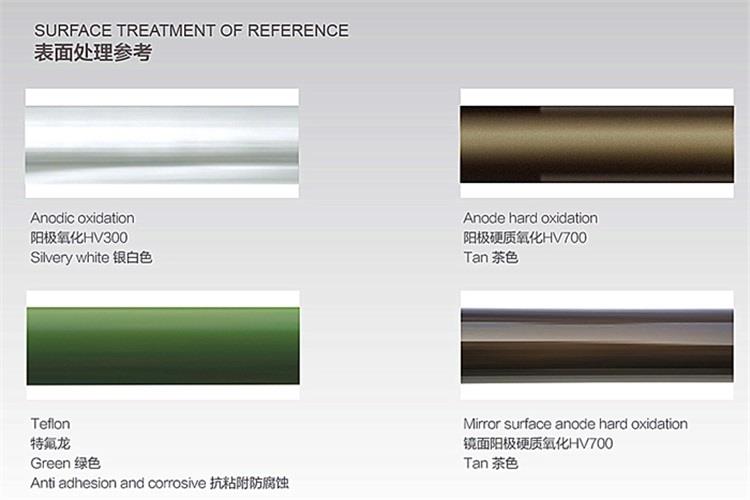

In the actual process, the anodizing of aluminum alloy is more, and it can be applied in daily life. The characteristics of this process make the surface of the aluminum piece have a hard protective layer, which can be used for the production of daily necessities such as kitchen utensils....

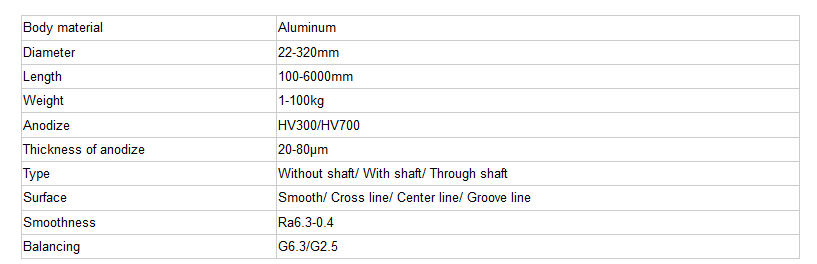

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

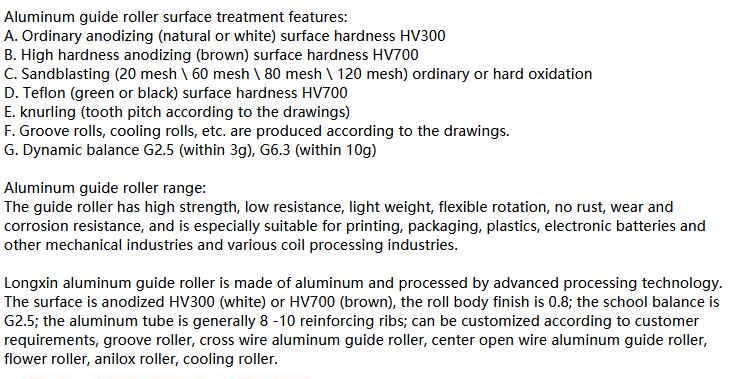

In the actual process, the anodizing of aluminum alloy is more, and it can be applied in daily life. The characteristics of this process make the surface of the aluminum piece have a hard protective layer, which can be used for the production of daily necessities such as kitchen utensils. However, the anodizing effect of cast aluminum is not good, the surface is not good, and it can only be black. The aluminum alloy profile is better. In the past ten years, China's aluminum oxidation coloring technology has developed rapidly. Many factories have adopted new technology and accumulated rich experience in actual production. There are many anodizing processes for aluminum and its alloys that have matured and are being developed, and suitable processes can be selected according to actual production needs. Before selecting the oxidation process, the aluminum or aluminum alloy material should be known, because the quality of the material and the composition of the material will directly affect the quality of the anodized aluminum product. In this regard, Hong Jiude and Comrade Fan Ji have devoted themselves to the discussion (see Electroplating and Finishing, No. 2, 1982, P.27). For example, if there are defects such as bubbles, scratches, peeling and roughness on the surface of the aluminum, all the rickets will still be revealed after anodizing. The alloy composition also has a direct effect on the surface appearance after anodization. For example, an aluminum alloy containing 1 to 2% manganese is brownish blue after oxidation. As the amount of manganese in the aluminum increases, the surface color after oxidation changes from brownish blue to dark brown. The aluminum alloy containing 0.6 to 1.5% of silicon is gray when oxidized, and white-gray when it contains 3 to 6% of silicon. Zinc-containing is an opalescent color, chrome is a golden to gray uneven color, and nickel is yellowish. In general, only aluminum containing gold containing more than 5% of titanium contains gold, which is oxidized to give a colorless, transparent, bright, smooth appearance. After selecting aluminum and aluminum alloy materials, it is natural to consider the selection of an appropriate anodizing process.

Application

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: through roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy