Web Guide

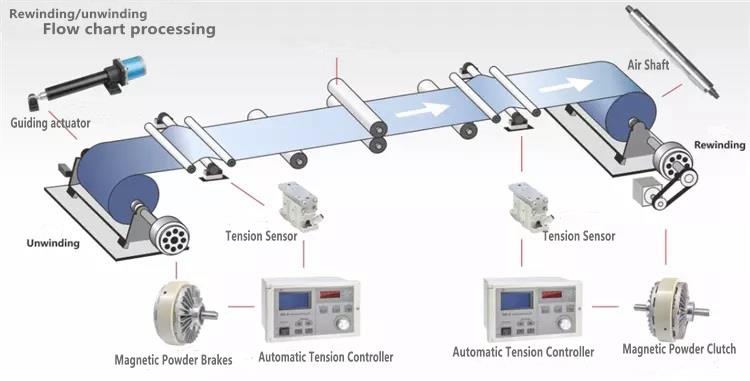

Guide systems are extremely diverse and are essential in the packaging, printing, labeling, construction materials, pulp, household paper, plastics, garments, cables, metal processing, nonwovens, corrugated paper processing and other industries. A typical web guide system includes a guide...

Guide systems are extremely diverse and are essential in the packaging, printing, labeling, construction materials, pulp, household paper, plastics, garments, cables, metal processing, nonwovens, corrugated paper processing and other industries.

A typical web guide system includes a guide controller, a guide sensor, a guide frame, and a driver.

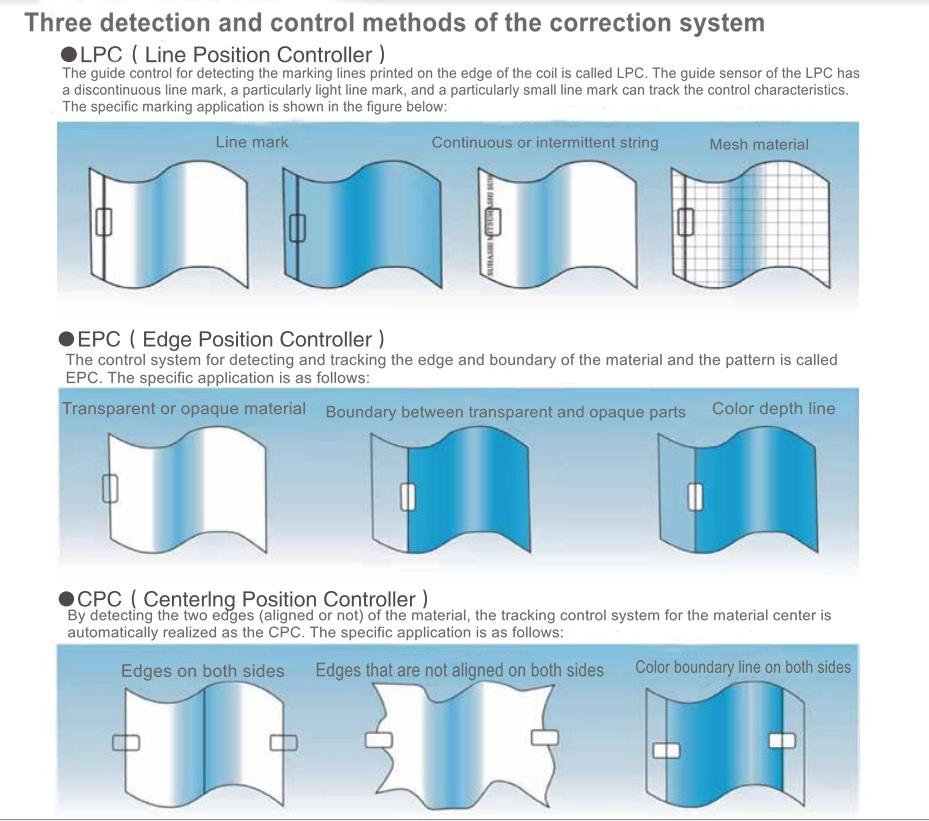

Web guide system principle: The infrared light/ultrasound/laser/visible light is monitored by the guiding sensor B, and the signal is sent to the controller A. After the controller finds that the coil has a positional drift, the controller D controls the swing of the guide frame C to correct the position of the coil according to a command preset by the controller. The automatic material rectification system uses a photoelectric sensor to detect the edge position of the coil, and sends the measured position error signal to the controller. After the control unit judges the process, the drive motor is controlled to correct the coil at the deviation position to the correct position. . The web guide System offers several different detection methods: edge detection, follow-up or alignment. The drive system uses low-speed synchronization, variable frequency speed regulation, stepping and servo motor drive, and the drive stroke and the coil offset are strictly proportional. The system can also be used with different probes to suit the needs of different coils, such as: infrared photoelectric, analog infrared photoelectric. The microcomputer digital controller provides precise control of the system's functions.

The web guiding system machine is a professional guiding device for the bag cutting machine and the printing machine. It is based on the electric eye tracking transmission signal to the guiding controller. The controller then outputs the guiding signal to the stepping motor at the bottom of the guiding system machine. The motor drives the screw at the bottom of the machine to move. The effect of correcting the deviation is achieved! The following describes the three installation methods of the photoelectric switch of the correcting machine.

Three installation methods for the photoelectric switch of the web guiding system:

1. Double switch single side control. The photocell is placed on one side of the material. The edge of the material is placed in the insensitive area of the photosensor. Advantages: The control error is small, and the position of the photoelectric head can be unchanged when the material width changes.

2. Single switch single side control. When the single-sided single-switch control is performed, the photo-electric head is placed on one side of the material. The edge of the material is placed under the photosensor spot. Advantages: The control error is small, the debugging is simple; when the material width changes, the position of the photoelectric head can be unchanged.

Disadvantages: If the edge is damaged, the tracking will force the material to tear. When the material is finished, the actuator will run to the limit position; without the balance point, the motor will rotate continuously.

3. Double switch bilateral control. Two photoelectric switches are placed on both sides of the material to keep the two photo heads in the same state. Advantages: If the edge of the material is broken, or the material is finished, it will not affect the operation. Disadvantages: Photoelectric corrector manufacturers believe that if the material width changes frequently, it is necessary to change the position of the photoelectric head frequently. If the distance between the optical axes of the two photoelectric heads is different from the material width, a guide error will occur.

Order Details

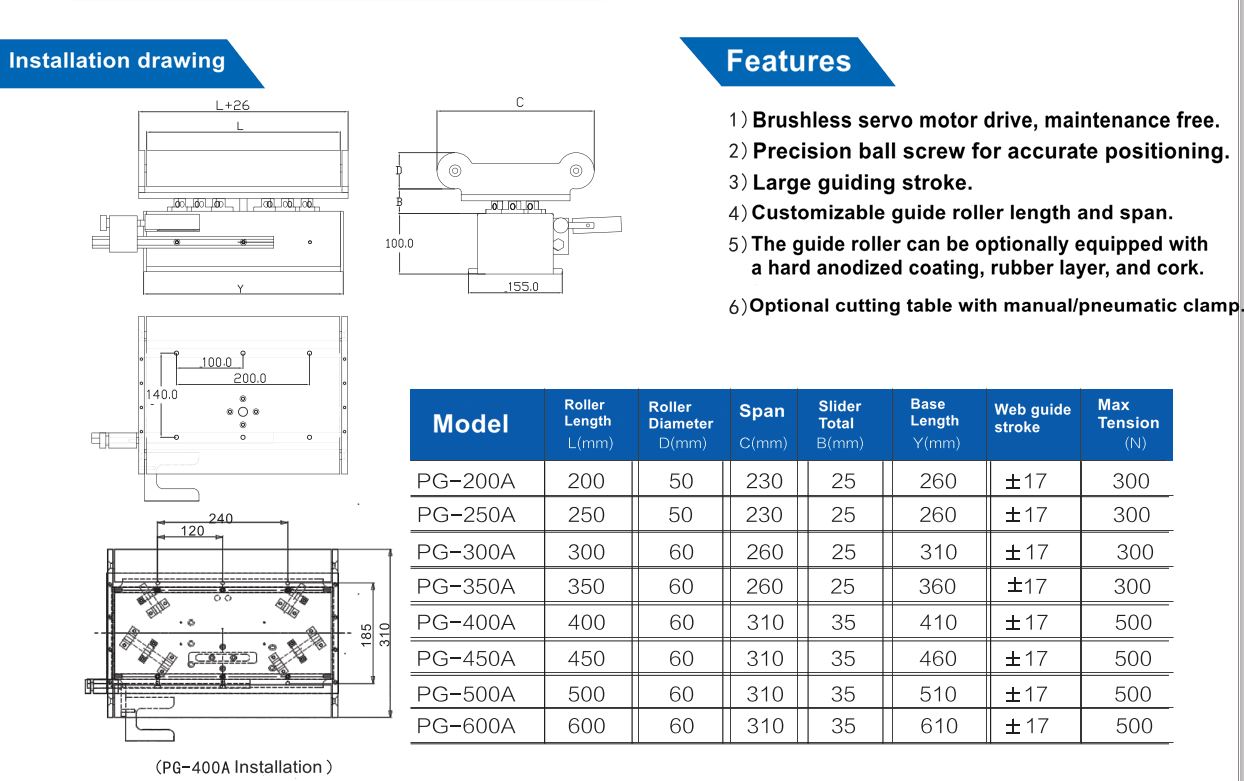

Item Name | PG series Web Guide Control System |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | depends on the model |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: web guide, China, manufacturers, suppliers, factory, quotation, pricelist, buy