Web Rewind

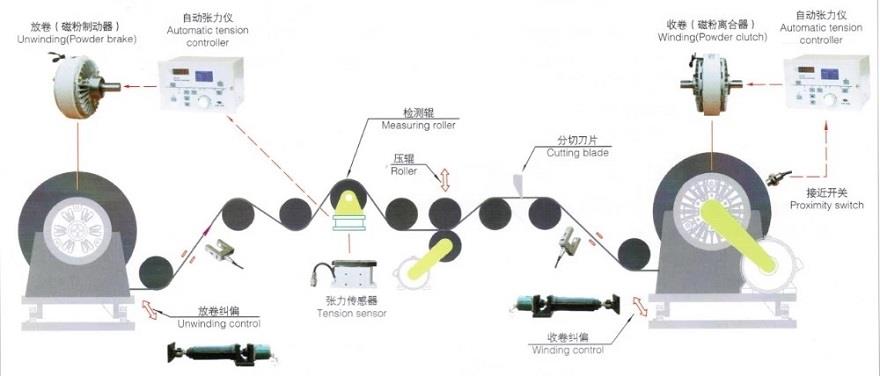

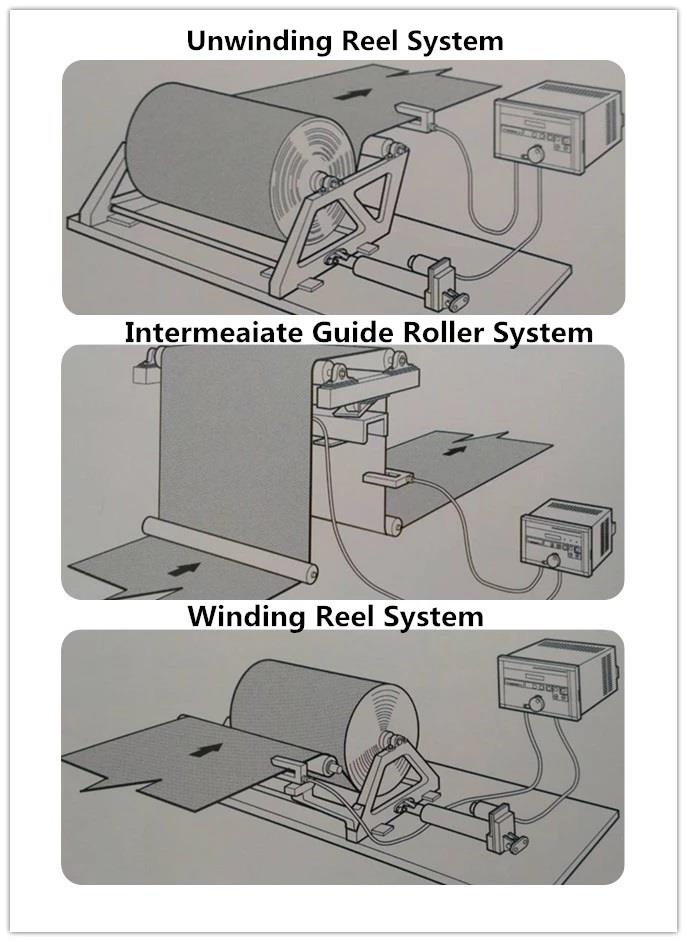

The installation example of the middle correction control system for winding and unwinding, explained as follows: ★ Material winding The photoelectric sensor or the gas sensitive probe is mounted at a position that moves together with the take-up station, and is corrected by a motor screw or a...

The installation example of the middle correction control system for winding and unwinding, explained as follows:

★ Material winding

The photoelectric sensor or the gas sensitive probe is mounted at a position that moves together with the take-up station, and is corrected by a motor screw or a hydraulic cylinder.

Make the rolled material unbiased relative to the sensor or probe, so that the collected volume is neat.

★ Material unwinding

The photoelectric sensor or the gas sensitive probe is fixed and close to the position of the discharging platform, and is corrected by the motor screw or the hydraulic cylinder.

The material being wound is walked unbiased relative to the sensor or probe.

★ Intermediate correction

For materials that travel longer distances, this device can be used before and after the middle machining operation to avoid the material being too far away from the normal direction of travel.

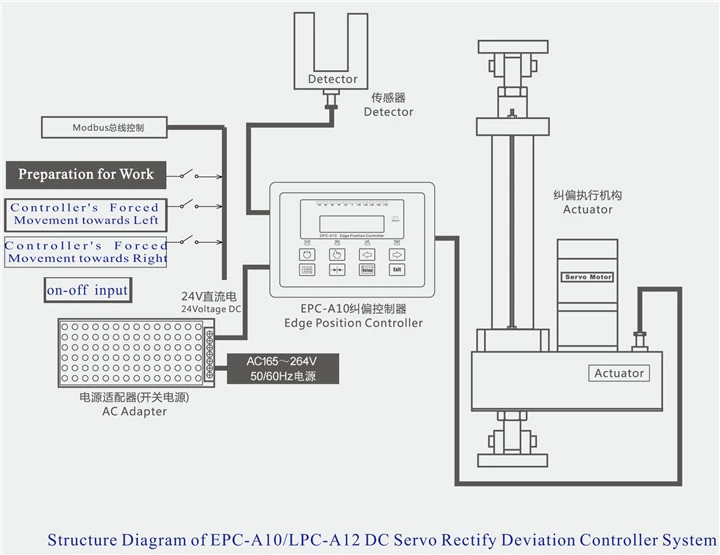

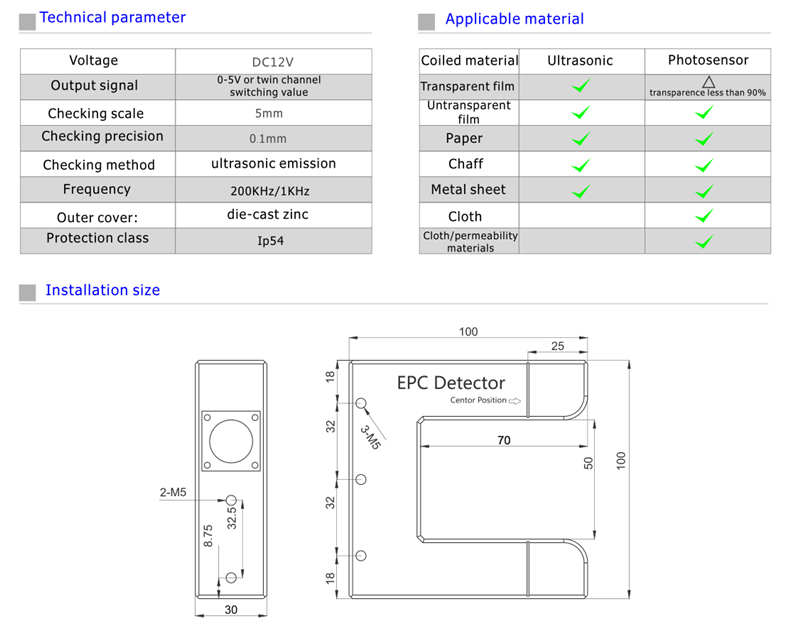

Edge Position Control system:

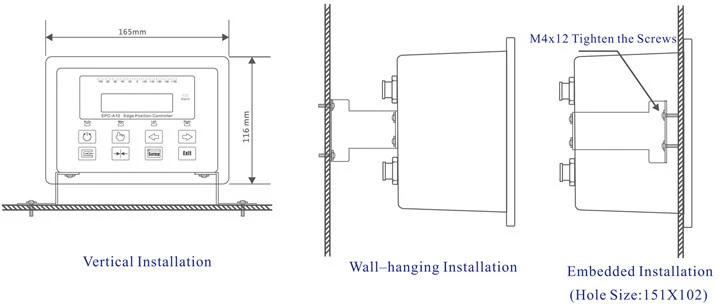

Installation :

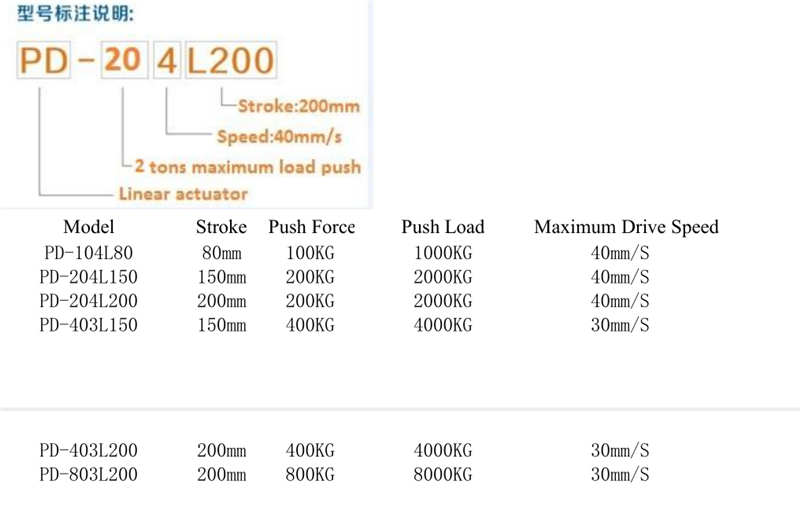

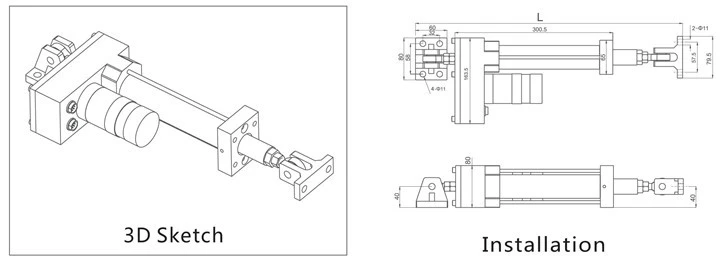

Actuator

Guide sensor

The utility model discloses an automatic deviation correcting and receiving system, which is used for winding a soft material belt, and the automatic correcting and receiving receiving system comprises: a reel, a motor, a correcting control device; the correcting control device includes a sensor, a correcting controller, and a correcting pusher, the sensor is disposed on one side of the soft strip, the correcting pusher is connected to the motor; and the sensor connecting station The correction controller is connected to the correcting pusher. Through the above manner, the automatic deviation correcting and receiving system of the utility model can adjust the movement of the reel by sensing the position change of the edge of the material belt and the material roll, thereby realizing the neat receipt of the material roll, ensuring the edge of the material roll is neat, and at any time. Adjust the tension of the tape.

The receiving and discharging correction system (winding and unwinding system) means that the coils produced by the manufacturer are always kept in the process of spraying, printing, punching, laminating, slitting or other coil winding. The technical side of the material is neatly aligned and its extensive use has brought great benefits to the industry. Correction control makes steel, corrugated, textile, printing, labeling, labeling, paper, plastic film, building materials, cables Automatic control of rubber, tires, non-woven corrugated paper processing industries.

Application

Packing

Order Details

Item Name | Pivot Web Guide Systems for unwind and rewind |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Weight | Depend on model set |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: web rewind, China, manufacturers, suppliers, factory, quotation, pricelist, buy