Aluminum Awning Roller Tube

Aluminum tube;aluminum pipe There may be one or more closed through holes, the wall thickness and the cross section are uniform, and are delivered in a straight line or in a roll. Widely used in automobiles, ships, aerospace, aviation, electrical, agricultural, mechanical and electrical, home and other industries.

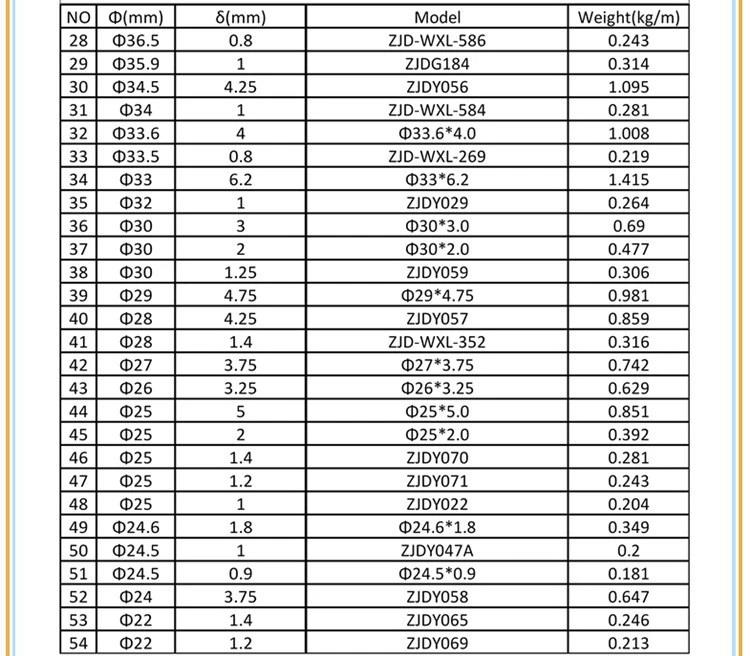

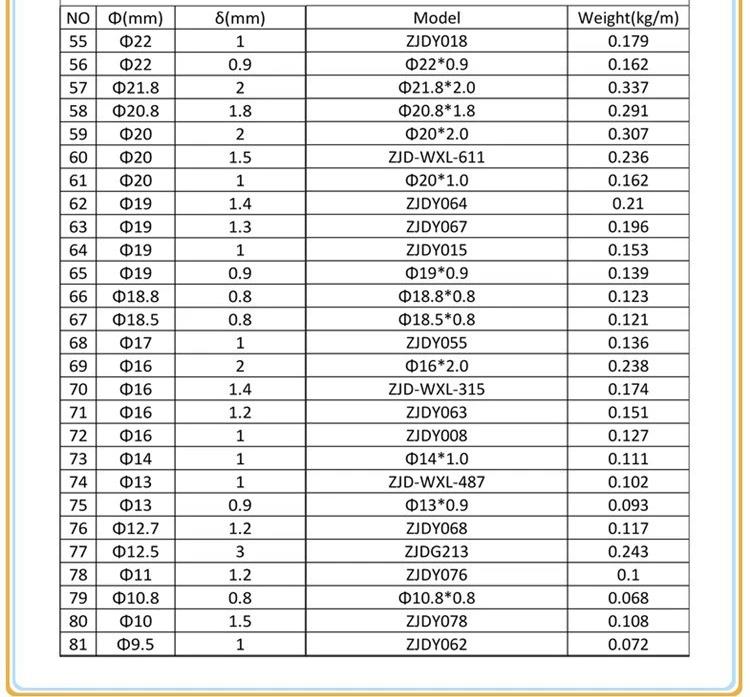

Aluminium Tube Specification | |||

Material | Aluminium Alloy or Non-alloy | ||

Grade | 1000 series: 1050,1060,1070,1080,1100,1435, etc 2000 series: 2011,2014,2017,2024, etc 3000 series: 3002,3003,3104,3204,3030, etc 5000 series: 5005,5025,5040,5056,5083, etc 6000 series: 6101,6003,6061,6063,6020,6201,6262,6082, etc 7000 series: 7003,7005,7050,7075, etc | ||

Standards | ASTM, ASME,EN, JIS, DIN,GB/T etc | ||

Outer Diameter | 6-720mm | ||

Thickness | 0.5-68mm | ||

Length | 3000-6000mm | ||

1. The welding rod cannot be heated by the welding torch and then the welding powder is taken because the melting point of the electrode is too low.

2. The successful one-time welding effect is better, because the aluminum tube melting and cutting tool point is too low, and the aluminum tube is easily deformed when the second time is reheated.

3. The liner must be placed with a wet towel to protect it in place, because the welding space is very small, so be sure to pay attention to the protection of the refrigerator.

4. The torch flame should not be too long, and must be heated with a slight fire, otherwise the dispersant aluminum tube is very easy to melt. 5. After the welding is completed, it is necessary to wait for the special slurry of nylon wire for two or three minutes, and then the cement storage tank can be contacted, otherwise the solder joint is easy to leak.

6. The electrode must be evenly coated with flux to ensure the quality of the solder joint.

7. The welding time should not be too long. Because the melting point is too low, the aluminum tube wall will melt or become thinner and the pressure will be easily leaked.

8. The welding rod cannot be heated by the welding torch and then the welding powder is taken because the melting point of the electrode is too low.

The maximum heating degree of the aluminum tube. For aluminum tubes and high alloy steels, how should the heating temperature range of the tube blank be determined? It is difficult to determine by state. Therefore, in the production of steel pipes of the new steel grade, the hottest temperature range of various alloy steels is determined by hot torsion method or by measuring the critical reduction ratio. The hot torsion method is to heat the cylindrical sample to different temperatures and then torsion on a hot torsion machine, and record the number of torsion turns and torsion moment when the sample is twisted. The number of torsion turns and the torsional moment are small when the twist is broken. The temperature range is the best concentration range for the plasticity of the steel.

Order Details

Item Name | Aluminum Roller Tube |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum awning roller tube, China, manufacturers, suppliers, factory, quotation, pricelist, buy