Aluminum Barrel Roller

Quick description: set up and commissioning of aluminum rollers Published roller heads and bearings ought to always be correctly lubricated. if the lubrication is poor, it will cause the damage of the printing plate aluminum roller roller head and the bearing, and the space will increase,...

Quick description: set up and commissioning of aluminum rollers

Published roller heads and bearings ought to always be correctly lubricated. if the lubrication is poor, it will cause the damage of the printing plate aluminum roller roller head and the bearing, and the space will increase, resulting in choppy printing at the ink.

1, loading and unloading

The printing plate roller have to be matched with the bearing during installation to ensure a sure diploma of precision and cleanliness. the aluminum roller need to be lightly dealt with and must no longer collide with the shaft head and the rubber layer to keep away from harm, bending and damage of the rubber layer.

2, lubrication

Printed curler heads and bearings have to constantly be efficiently lubricated. if the lubrication is terrible, it will purpose the damage of the printing plate aluminum roller roller head and the bearing, and the gap will growth, resulting in choppy printing on the ink. at the identical time, the printing bar marks may be due to defects which include the printing plate leaping and sliding. if there is no effective lubrication for a long term non-stop operation, the bearing and the shaft middle might be heated, causing the rubber floor of the printing plate to be thermally expanded and worn, so that the rubber floor of the two heads is pocked, glued and cracked.

Three, debugging

The strain among the printing plate curler and the aluminum curler and the printing plate need to be adjusted in step with the pliability and hardness of the rubber and its role within the printing technique. usually, the feeler gauge of o.15~o.20mm is used (the feeler gauge have to be lubricated to keep away from the take a look at is done on the damaged rubber floor. the radial contact pressure of the printing plate curler must be uniform. in any other case, long-term operation will motive the printing plate curler on the quit of the strain to supply pitting, gelation, cracking, and starting of the rubber.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

Widespread for judging whether or not the roller of the aluminum manual roller is good or bad.

The curler of the aluminum manual roller is a small component inside the belt conveyor, and the shape isn't complicated, however it isn't smooth to fabricate a high great curler.

The position of the rollers is to aid the conveyor belt and cloth weight. the curler ought to be bendy and reliable. lowering the friction among the conveyor belt and the idler curler performs a key position inside the life of the conveyor belt, which money owed for extra than 25% of the whole price of the conveyor.

Despite the fact that the idler is a small component in the belt conveyor and the structure is not complicated, it isn't always smooth to fabricate a high best curler.

1. aluminum guide curler idler dustproof performance.

2. aluminum manual curler loafer water-proof overall performance.

Three. aluminum manual roller idler radial runout overall performance.

4. axial displacement overall performance of aluminum manual roller idler.

5. axial bearing capacity of aluminum guide curler idler.

6. aluminum manual curler idler effect resistance.

7. aluminum guide roller idle roller life.

Application

Order Details

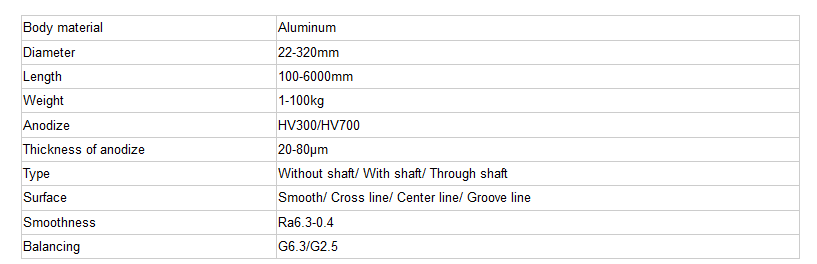

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum barrel roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy