Aluminum Frame Roller

Aluminum tubes are mainly divided into the following According to the shape: square tube, round tube, pattern tube, shaped tube, global aluminum tube. According to the extrusion method: seamless aluminum tube and ordinary extruded tube According to the accuracy: ordinary aluminum tube and precision aluminum tube, of which precision aluminum tube generally needs to be re-processed after extrusion, such as cold drawing and rolling. According to thickness: ordinary aluminum tube and thin-wall aluminum tube Performance: corrosion resistant and light weight.

Detailed introduction and use of aluminum tubes

There may be one or more closed through holes, the wall thickness and the cross section are uniform, and are delivered in a straight line or in a roll. Widely used in automobiles, ships, aerospace, aviation, electrical, agricultural, mechanical and electrical, home and other industries.

classification

Aluminum tubes are mainly divided into the following

According to the shape: square tube, round tube, pattern tube, shaped tube, global aluminum tube.

According to the extrusion method: seamless aluminum tube and ordinary extruded tube

According to the accuracy: ordinary aluminum tube and precision aluminum tube, of which precision aluminum tube generally needs to be re-processed after extrusion, such as cold drawing and rolling.

According to thickness: ordinary aluminum tube and thin-wall aluminum tube

Performance: corrosion resistant and light weight.

characteristic

It is a kind of high-strength hard aluminum, which can be heat-treated and strengthened. It has medium plasticity in annealing, quenching and hot state. It has good spot weldability. The aluminum tube has the tendency to form intergranular cracks when using gas welding and argon arc welding. After quenching and cold work hardening, the machinability is good and it is not good in the annealed state. The corrosion resistance is not high, and the anodizing treatment and painting method or the surface is coated with an aluminum layer to improve the corrosion resistance. It can also be used as a mold material.

Aluminum tube advantages:

First, the advantages of welding technology: thin-walled copper-aluminum tube welding technology suitable for industrial production, known as the world-class problem, is the key technology for the aluminum-based copper of the air-conditioner connecting tube.

Second, the service life advantage: from the inner wall of the aluminum tube, since the refrigerant does not contain moisture, the inner wall of the copper-aluminum connecting tube does not corrode.

The third is the energy-saving advantage: the connecting line between the indoor unit and the outdoor unit of the air conditioner, the lower the heat transfer efficiency, the more energy-saving, or the better the heat insulation effect, the more power-saving.

Fourth, excellent bending performance, easy to install, transfer machine

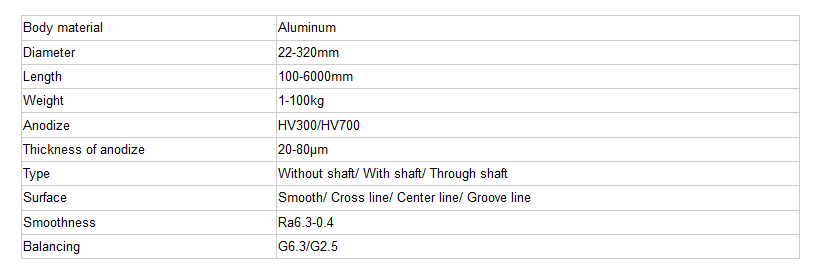

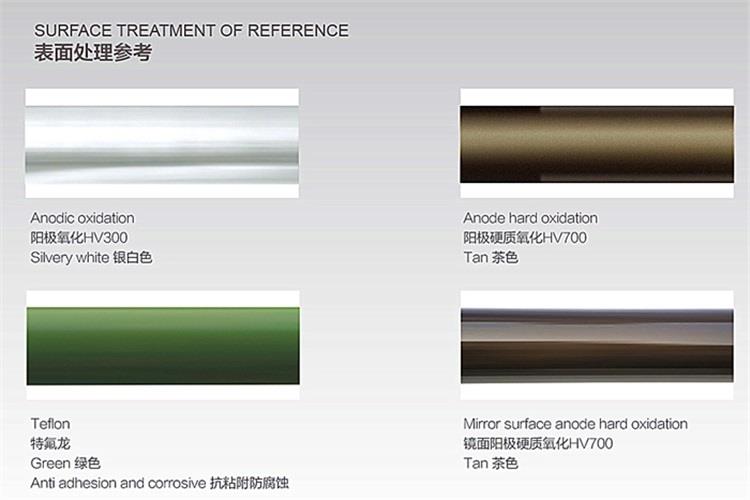

Surface treatment

Chemical treatment: oxidation, electrophoretic coating, fluorocarbon coating, powder coating, wood grain transfer

Mechanical treatment: mechanical drawing, mechanical polishing, sand blasting

use

Aluminum tubes are widely used in various industries, such as: automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, home, etc. Aluminum tubes have become ubiquitous in our lives.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

Application

Order Details

Item Name | Aluminum Roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum frame roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy