Carrying Roller

The characteristics and use of aluminum guide rolls First, the working principle of aluminum guide roller When the sheet rotates following the roller body, the sheet drives the tilting wheel to rotate, and the tilting wheel drives the sheet to reciprocate outward and inward. The sheet moves...

The characteristics and use of aluminum guide rolls

First, the working principle of aluminum guide roller

When the sheet rotates following the roller body, the sheet drives the tilting wheel to rotate, and the tilting wheel drives the sheet to reciprocate outward and inward. The sheet moves outward when moving from 0o to 180o, and moves inward when moving from 180o to 360o. When the substrate is wrapped around 0o--180o, it is flattened by axial stretching of the outwardly moving sheet.

Second, the characteristics of aluminum guide rollers

It has strong flattening ability and can withstand the tensile force of large substrate. It is suitable for thicker substrates. It is easy to flatten and debug, just turn the mandrel slightly, and it can be eliminated after various adjustments. Wrinkles, no need to adjust frequently.

Third, the use of aluminum guide roller

Aluminum guide rolls can be widely used in textile, printing and dyeing, printing, paper, film, composite, coating and non-woven fabrics. The applicable linear speed is less than 90m/min, and the applicable substrate wrap angle is 90o--180o.

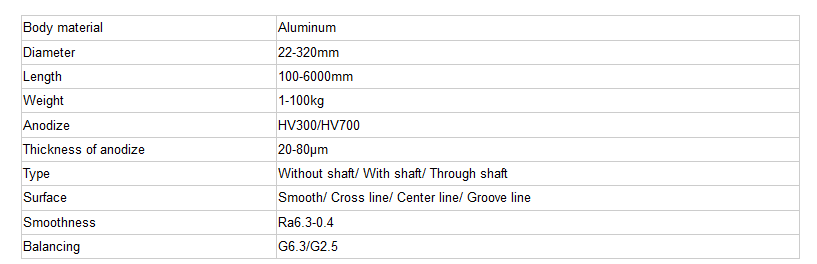

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

Aluminum guide roll surface damage form

1, roll surface crack

Cracks are divided into normal cracks and abnormal cracks. Normal cracks are also called hot cracks. The cracks are gradually broken due to thermal stress caused by multiple temperature cycles, which is a micro-surface phenomenon that occurs on the roll surface; The normal crack is a thermal shock crack caused by accidents such as slippage, sticking steel, stuck steel, stacking steel, and tailing during the rolling process, and a certain depth and ductility crack is formed locally on the surface of the roll surface.

2, indentation

The aluminum guide roll indentation mainly refers to the intrusion of foreign matter such as iron oxide scale due to cleaning reasons during the production process, and irregular or irregularly shaped pits which are continuously or discontinuously distributed on the roll surface.

3, oxide film shedding

At the beginning of rolling, after a period of hot rolling, a thin layer of silver-gray or light-blue oxide film is formed on the surface of the roll, which is important for protecting the roll surface and improving the surface quality of the rolled piece due to the repeated action of the rolling force. The oxide film is caused to generate microcracks around the carbide; when the roll cooling capacity is insufficient, it is difficult to form a dense oxide film on the roll surface, and the oxide film is rapidly deteriorated even if it is formed. When the rolling is unreasonable, the oxide film is rapidly destroyed during the formation process, which causes the oxide film to fall off, leaving defects such as meteor spots on the roll surface, resulting in an increase in the roughness of the roll surface and an increase in the wear amount.

4, bonded steel, abnormal wear, etc.

Due to the abnormality of rolling, the adhesion between the roll surface and the rolled piece occurs, and the steel is stuck; the process parameters during rolling are unreasonable, resulting in excessive consumption of the same wide-kilometer roll, resulting in uneven wear on the roll surface.

Application

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: carrying roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy