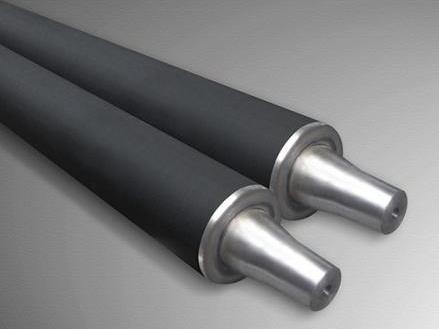

Fiber Roller For Labeling Machine

Carbon fiber rollers are usually made of carbon fiber composite materials through a winding process. The nature of composite materials is a multiphase composition material with more pronounced anisotropy. These materials are usually characterized by superior physical and chemical properties and...

Carbon fiber rollers are usually made of carbon fiber composite materials through a winding process. The nature of composite materials is a multiphase composition material with more pronounced anisotropy. These materials are usually characterized by superior physical and chemical properties and uniform internal interface distribution. . The carbon fiber reinforced carbon fiber composite material is characterized by light weight, high strength and low density carbon fiber composite material, which can greatly reduce the weight of the roller, effectively reduce the weight of the paper machine equipment as a whole, and effectively reduce the weight of the roller. The overload of the parts and the excessively high rotation speed cause damage to the coating on the surface of the roller and the breakage of the roller shaft due to the increase in the deflection of the roller. While reducing the damage rate of roller parts, it contributes to the reduction of operating costs.

On the other hand, carbon fiber composite materials have strong corrosion resistance and fatigue resistance. The rollers made of this material have a long service life, can adapt to large working temperature differences, have high portability during installation and removal, and require the machine to run at high speed for a long time. In paper mills, maintenance frequency can be reduced, which has outstanding significance for production safety and production efficiency.

Material: | carbon fifber |

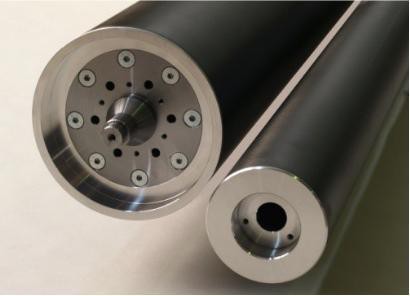

Diameter: | 50 mm-250 mm |

Length: | 100-6000 mm |

Balancing: | Dynamic balance |

At the same time, with the increasing speed of the paper machine and the use of new structures, the rolls must meet the new requirements in terms of load direction, size and manufacturing accuracy. The outer diameter tolerances, dynamic balance, Surface finish, cylindricality, coaxiality, etc. are also important considerations. The strong corrosion resistance of carbon fiber can also resist the corrosion of polyvinyl acetate glue, which is very convenient for maintenance and cleaning. After the carbon fiber is laminated, the coefficient of friction of the epoxy resin layer is small, and the surface of the rubber roller is basically not abraded, which reduces the occurrence of rubber leakage and rubber flipping on both sides, thereby ensuring the cleaning of the rubber roller area and largely solving the rubber roller The problem of easy damage strongly guarantees the normal operation of the equipment and the stability of the product quality.

Packing

Order Details

Item Name | Carbon Fiber Rollers |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients’demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: fiber roller for labeling machine, China, manufacturers, suppliers, factory, quotation, pricelist, buy