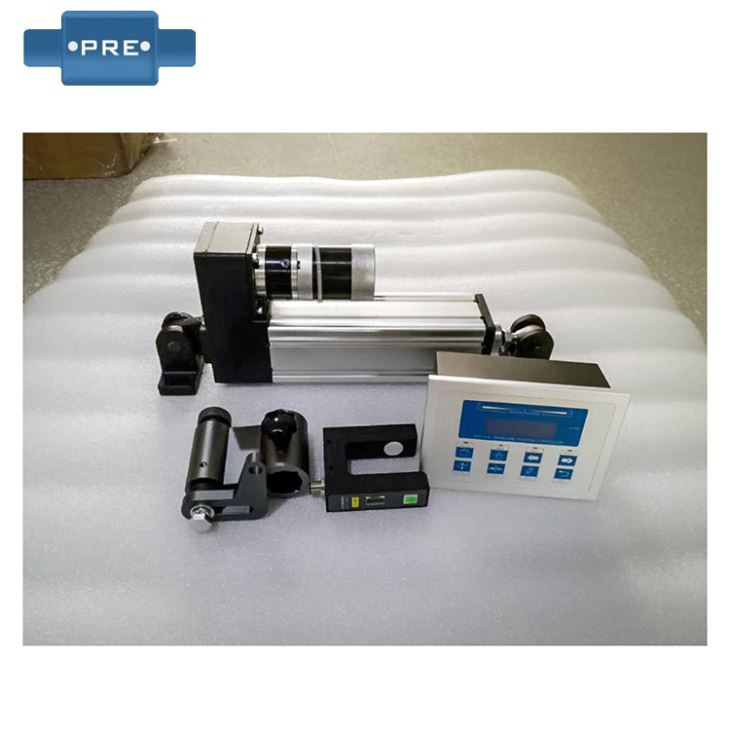

High Speed Actuator

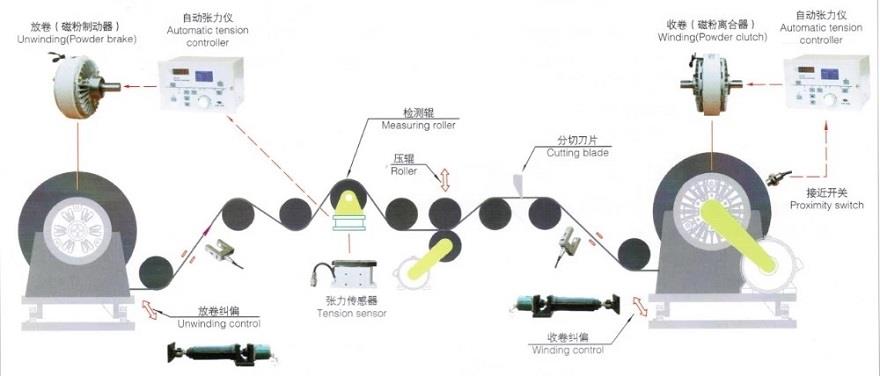

The coil rectification control system is a closed-loop controller, controller, sensor, and linear guide mechanism that form the basic part of the closed-loop control. First, the rectification sensor detects the edge or line of the coil, and the system automatically reads the actual position and...

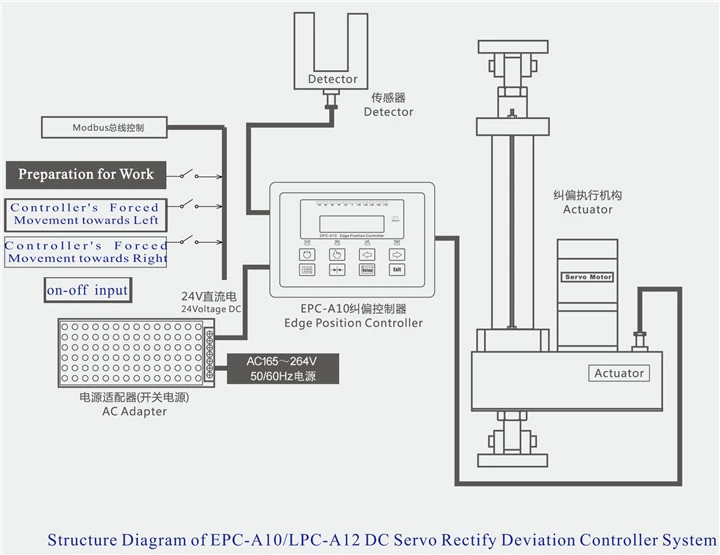

The coil rectification control system is a closed-loop controller, controller, sensor, and linear guide mechanism that form the basic part of the closed-loop control. First, the rectification sensor detects the edge or line of the coil, and the system automatically reads the actual position and design of the coil. The offset of the position is converted, and the offset is converted into a proportional electrical signal to the controller. The signal is amplified and calibrated by the controller, and then output to the linear driver. The linear driver drives the correcting and guiding according to the magnitude of the signal. The mechanism returns the coil to the set position. The drive signal of the current drive is only proportional to the amount of deflection of the coil, which allows precise control of the various coils and correction systems.

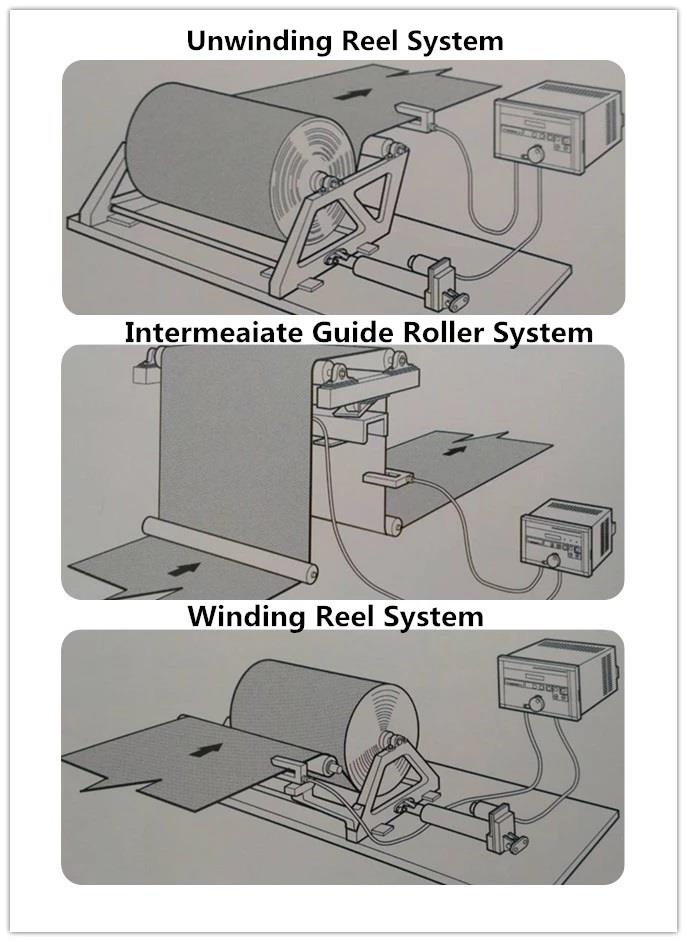

- Industrial control systems for steel, corrugated, textile, printing, labeling, labeling, paper, plastic film, building materials, cables, rubber, tires, etc. Correction control refers to the technical operation of the coil produced by the manufacturer during the spraying, printing, punching, laminating, slitting or other coil winding process, always keeping the sides of the coil neat and consistent. Because the edge of the coil is not aligned, it will cause subsequent step errors, resulting in material waste or downtime adjustment. Therefore, when processing the processed coil, it is necessary to perform a timely correcting operation on the offset coil, which is called rectification. The entire process of the device constitutes a set of correction systems. Correction systems are extremely diverse and are essential in the packaging, printing, labeling, construction materials, pulp, household paper, plastics, garments, cables, metal processing, nonwovens, corrugated paper processing and other industries. A typical correction system includes a correction controller, a correction sensor, a correction frame, and a driver.

Edge Position Control system:

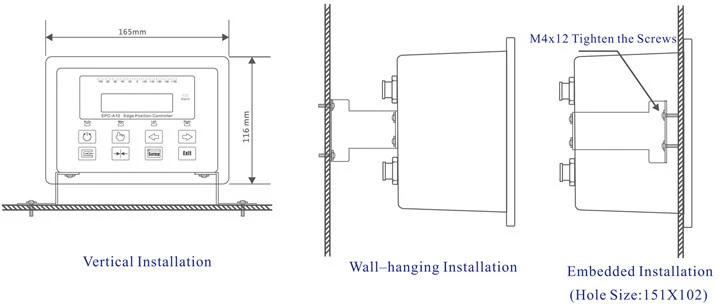

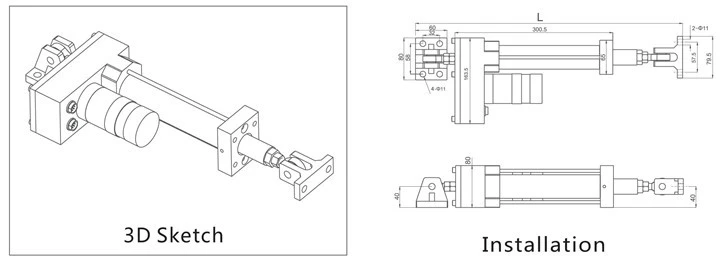

Installation :

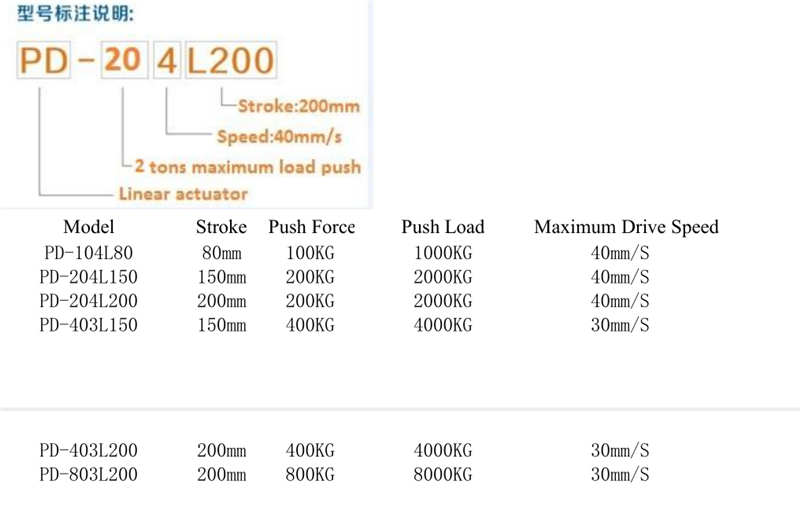

Actuator

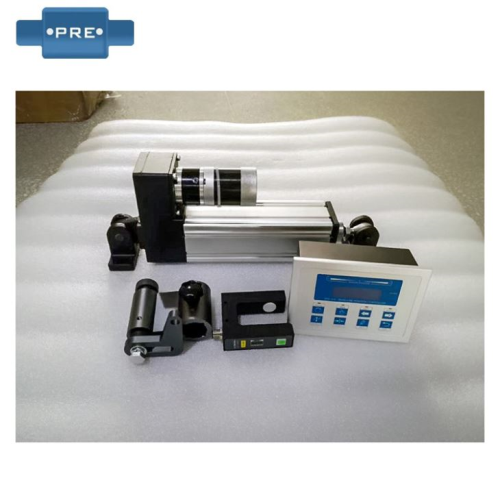

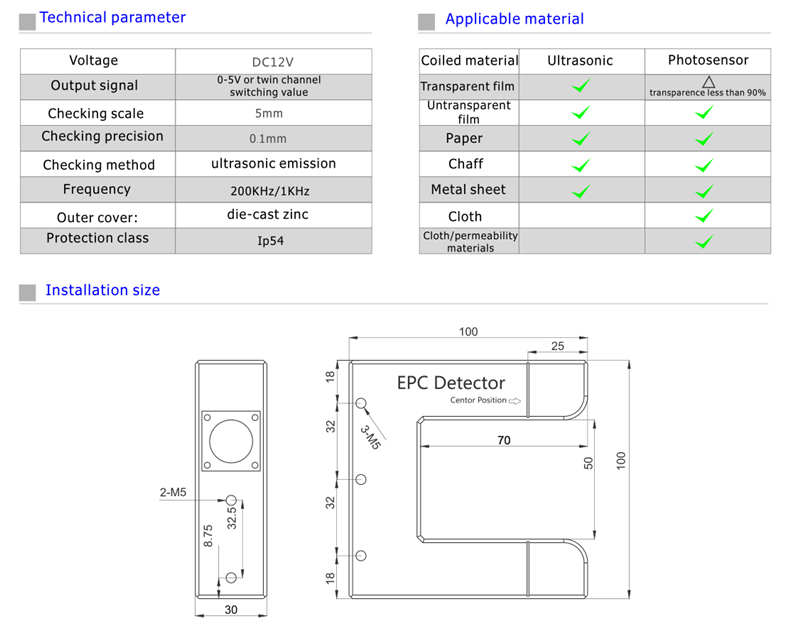

Guide sensor

Things to be aware of when using a guide

A common guide control system can be implemented. However, if the material roll speed needs to be changed, and the ordinary corrector can not change the rectification speed, it will lead to the phenomenon that the curling cannot be corrected, the unevenness of the material thickness and various mechanical damages, resulting in the material on the production line. The phenomenon of movement and one-way deviation causes the machining operation in the middle section to be difficult to match, or the movement of the front and rear sections is uneven, resulting in loss of many materials and difficulty in subsequent processing. The photoelectric-to-edge line-to-line device can solve this problem. The corrector is used for: coating machine, self-adhesive machine, laminating machine, slitting machine, rewinding machine, packaging and printing machinery, etc.

Guide system principle: The infrared light/ultrasound/laser/visible light is monitored by the corrector B to monitor the operation of the coil, and the signal is sent to the controller A. After the controller finds that the coil has a positional drift, the controller D controls the swing of the correction frame C to correct the position of the coil according to a command preset by the controller. The automatic material rectification system uses a photoelectric sensor to detect the edge position of the coil, and sends the measured position error signal to the controller. After the control unit judges the process, the drive motor is controlled to correct the coil at the deviation position to the correct position. .

The guide control system (guide system) is a closed-loop controller, controller, sensor, and linear guide mechanism that form the basic part of the closed-loop control. First, the corrector detects the edge or line of the coil.

Application

Packing

Order Details

Item Name | Pivot Web Guide Systems for unwind and rewind |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Weight | Depend on model set |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: high speed actuator, China, manufacturers, suppliers, factory, quotation, pricelist, buy