Metal Replacement Rollers

The aluminum guide roller has the advantages of high unit strength, light weight, small inertia, bright surface and no rust, and is widely used in embossing printing, coating, coating, blown film, lamination, coating, slitting, paper making, textile, etc. production line. The production of...

The aluminum guide roller has the advantages of high unit strength, light weight, small inertia, bright surface and no rust, and is widely used in embossing printing, coating, coating, blown film, lamination, coating, slitting, paper making, textile, etc. production line. The production of aluminum alloy guide rolls has passed the most stringent raw material extrusion production process. The high-strength special section and ribs can greatly enhance the rigidity of the aluminum tube. The excellent hot assembly process and the surface finishing of the CNC lathe can achieve the highest combination of products. Strength and precision, good linearity and concentricity, precise high-speed dynamic balance system can ensure static balance and high-speed dynamic balance performance (up to ISO1940 G1 grade), ensuring that aluminum rollers run at high speed on the machine without vibration, but different The surface treatment provides different application requirements, and the new aluminum rollers can greatly improve the performance of your machine.

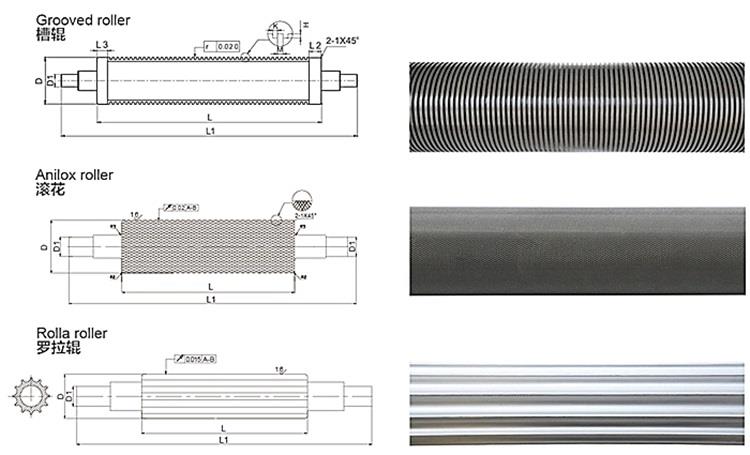

The structure of the aluminum guide roller can be roughly divided into:

(1) Hollow aluminum roller: The inner bearing type structure, the bearing is assembled in the inner bearing hole at both ends.

(2) Coaxial aluminum roller: The steel body or stainless steel shaft end is combined at both ends of the roller body, which is an integrated structure.

(3) Water-passing aluminum roller: cooling or heating liquid enters and exits through both sides and circulates in the roller body.

(4) Special rollers: various special structural rollers processed according to the drawings.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

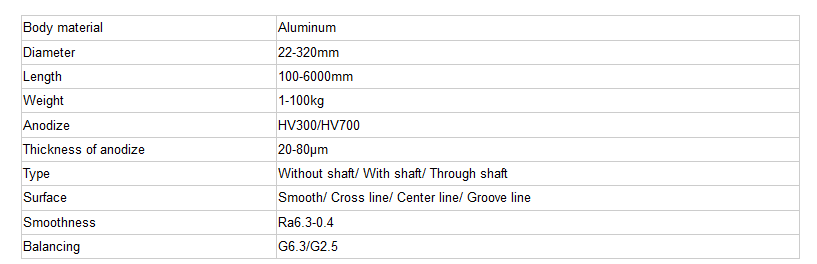

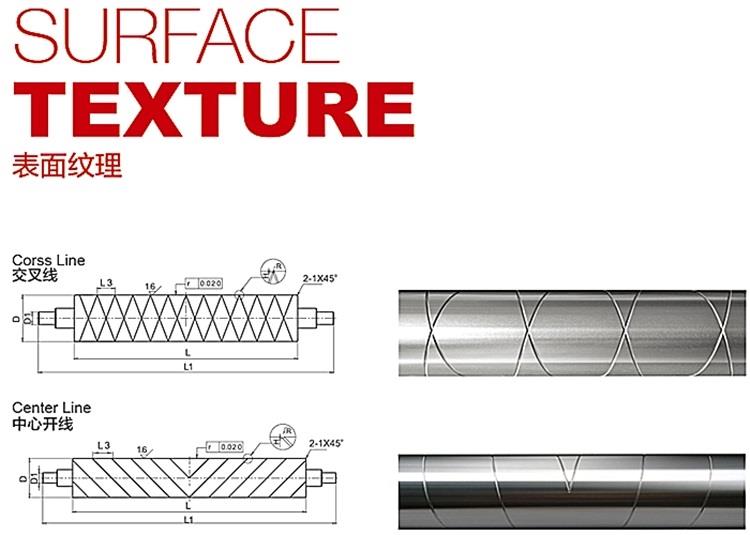

Different surface processing methods for aluminum guide rolls:

(1) Glossy surface: surface with smooth and low resistance, which can reach different surface roughness Ra0.3~Ra6.3 according to requirements

(2) Surface thread: Commonly used cross thread and center unfolding line (two points from the center, extending to both ends).

(3) Concave and convex surface: Various concave, convex and arc-shaped surfaces can be processed by CNC lathe.

(4) Sand blasting or shot peening: sand blasting or shot peening can obtain a rough surface and increase friction.

(5) Knurling or network cable: Different sizes of flower surface can be provided according to customer requirements.

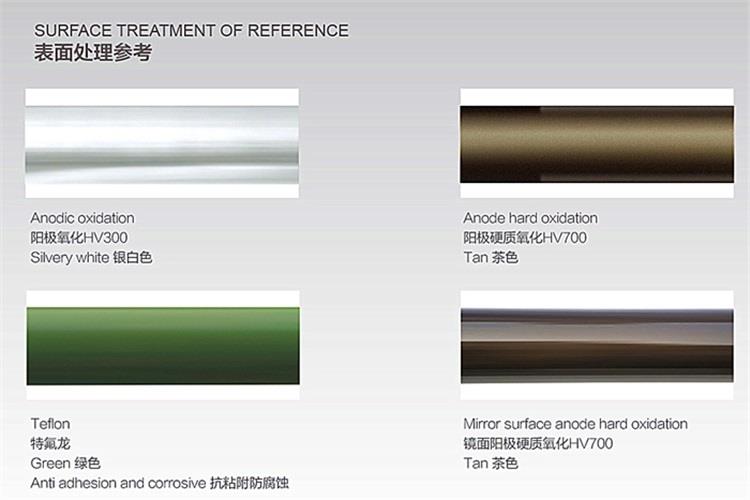

Different surface treatments or coatings for aluminum guide rolls.

(1) Universal white oxidized surface: moderate surface hardness HV300, low cost, can also provide different color surface (such as pure black) according to customer requirements, suitable for low tension film industry.

(2) Brown hard oxidized surface: high surface hardness HV700 and 0.1mm or more oxide film thickness, Taiwan introduced oxidation technology, high hardness and high abrasion resistance can be applied to various high tension and thick materials, which can be greatly improved The life of the aluminum roller.

(C) Teflon surface: The special Teflon coating makes the ink easy to clean and provides moderate anti-stick properties.

(4) Rubber surface: The aluminum roller is used as the core shaft, and different rubberized layers can provide versatility of different characteristics and different hardnesses.

(5) Industrial hard chrome surface: higher surface hardness and corrosion resistance, surface roughness can be as low as Ra0.01 (ultra-mirror surface), compared with traditional chrome-plated steel rolls.

Application

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: metal replacement rollers, China, manufacturers, suppliers, factory, quotation, pricelist, buy