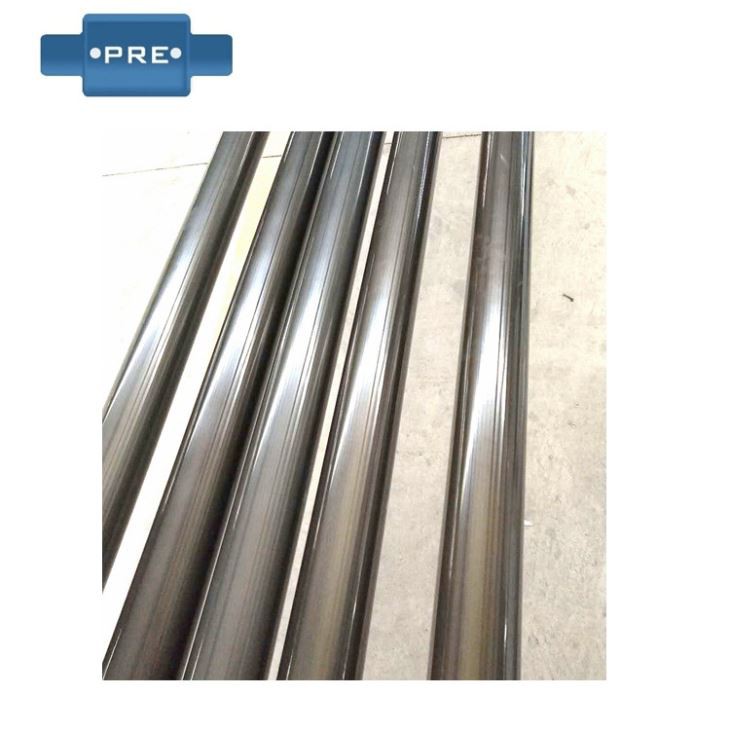

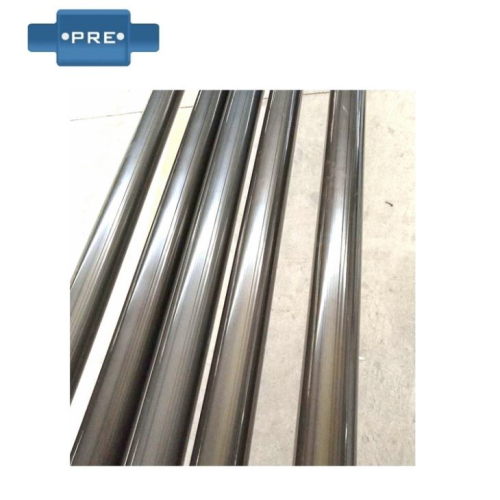

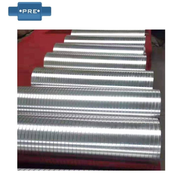

printer roller

Advantage 1) Single and two sides embossing: take place the steel roller for two sides embossing; replace rubber roller for loaded roller with single embossing. 2) Feasible embossing: adjust with different design and different embossing. 3) High elasticity: with quality when processing and...

1) Single and two sides embossing: take place the steel roller for two sides embossing; replace rubber

roller for loaded roller with single embossing.

2) Feasible embossing: adjust with different design and different embossing.

3) High elasticity: with quality when processing and embossing.

4) Good hardness and wear-resisting.

5) Excellent embossing effect.

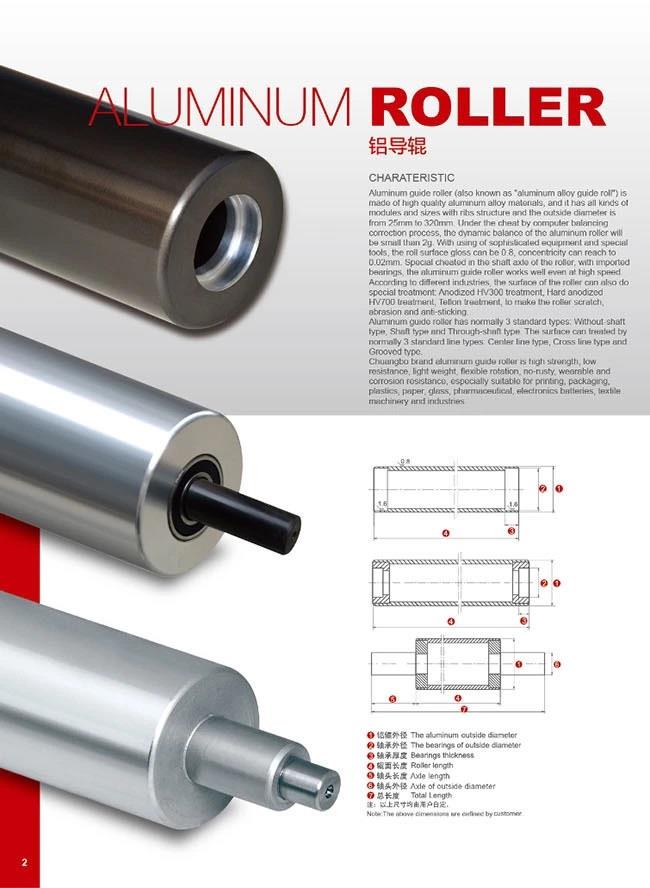

| Body material | Aluminum |

| Diameter | 22-320mm |

| Length | 100-6000mm |

| Weight | 1-100kg |

| Anodize | HV300/HV700 |

| Thickness of anodize | 20-80μm |

| Type | Without shaft/ With shaft/ Through shaft |

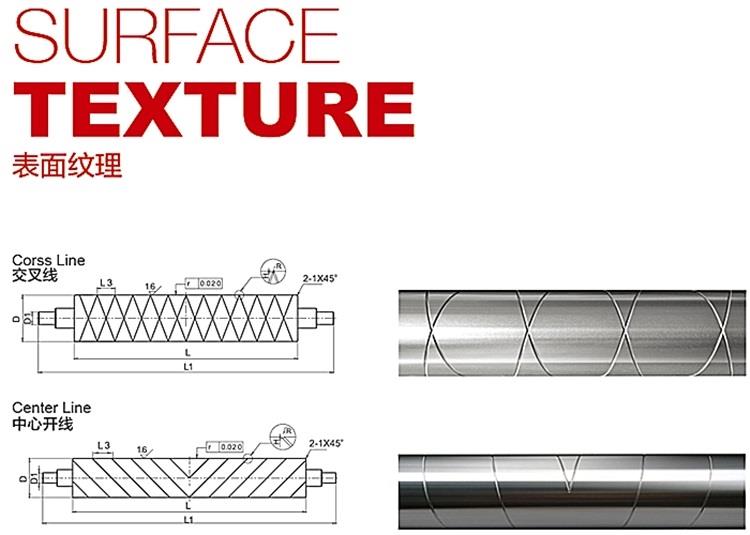

| Surface | Smooth/ Cross line/ Center line/ Groove line |

| Smoothness | Ra6.3-0.4 |

| Balancing | G6.3/G2.5 |

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

The guide rolls guide and drive the screen and felt of the wet end and drying section of the paper machine. The guide rollers of the two zones use the same bearing. However, different lubrication and sealing are used depending on the application location. In the old paper machine, the wet end section is usually lubricated with grease, and the drying section is lubricated with oil. In modern paper machines, both sections are lubricated with oil circulation. Due to different working conditions, the wet end and the drying section need to be lubricated with their respective oil circulation.

It is often seen that the larger the machine, the faster the speed. To this end, the inner ring of the bearing is mounted directly on the tapered roller neck by means of a tapered bore.

1. Wet end section

Bearings are affected by temperature at different locations in the paper machine. Especially when the paper machine is undergoing high pressure cleaning, it must be ensured that water cannot enter the bearing housing.

2. Drying section

The ambient temperature is about 95 ° C, which will result in a large length change, so the lubrication requirements are high. The bearing can work at temperatures up to 115 °C.

Printing plate use and maintenance

1, before printing

Check if there is any foreign matter between the roller and the roller, whether the printing plate roller is intact, whether the pressure between the rollers is uniform, confirm the normal, and clean and clean before printing.

2, in printing

The printing plate roller should always maintain a good contact state during operation, and the force is uniform. Regardless of the width of the printed product, the entire surface of the printing plate roller should be lubricated with ink; depending on the amount of ink accumulated between the printing plate rollers, the amount of ink should be adjusted in time to ensure the printing quality.

Under the premise of ensuring the printing speed, in order to prevent the ink from drying too fast, the viscosity of the printing plate roller is reduced, and the surface is crusted. The ink to be added with dry oil should be controlled to control the amount of dry oil to prevent the printing in operation. The plate roller does not apply ink and uneven ink transfer.

3, after printing

It is necessary to disengage the roller and the roller and the roller from the printing plate in time, and remove the load pressure to prevent the rubber surface from being deformed by static pressure. It is necessary to clean the residual ink on the surface of the printing plate in time to prevent the ink stick, ink film, ink smear and dirt from floating on the rubber surface. (In particular, the ink block on both ends of the nylon roller) will crush and damage the rubber surface when it is operated again. The smoothness will cause serious pitting and slag.

4, printing plate roller cleaning

The printing plate roller should be cleaned before and after printing by a special cleaning agent to keep the surface of the printing plate smooth and ready for use.

If the cleaning is not timely, the ink will adhere to the micropores through the veiled micropores on the surface of the printing plate, and the paper wool and dirt will adhere to the surface of the printing plate roller. If the parking time is too long, the ink conjunctiva will cause the two roller contact surfaces to adhere, and then the rubber surface will be torn when driving, so that the printing plate roller will be scrapped.

If the cleaning is not in place, glazing will occur, resulting in reduced ink retention, ink transfer, and even deinking. The glaze makes the surface hardness of the printing plate surface increase and the elasticity decreases, and at the same time, the wear of the printing plate roller is accelerated, which causes pitting and cracking of the rubber surface, causing slag phenomenon and affecting the printing quality.

Application

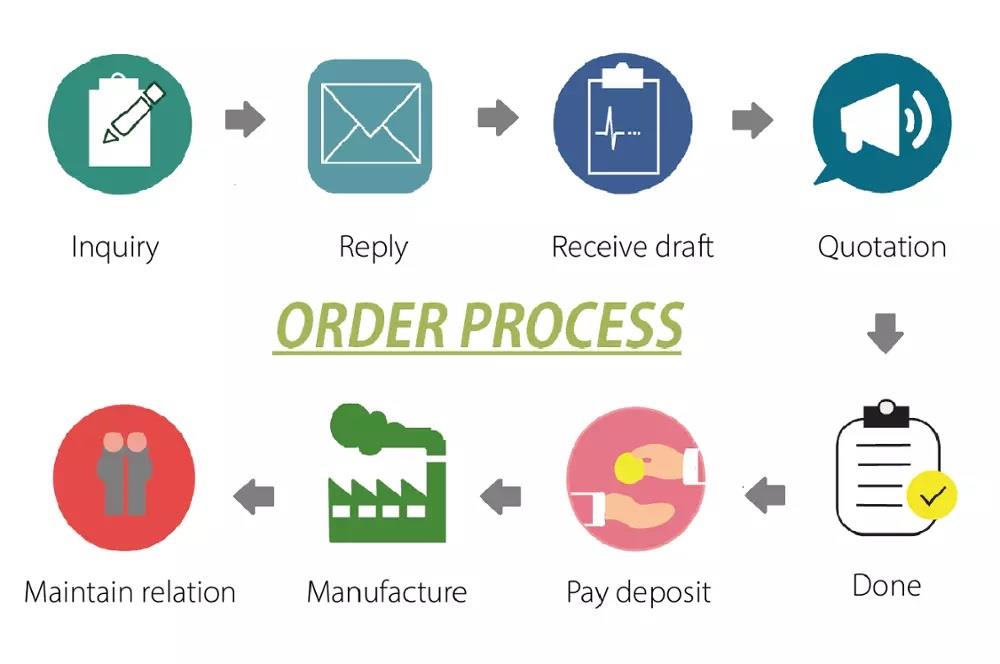

Order Details

Item Name | Aluminum idler roller/Printer roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: printer roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy