Side Roller

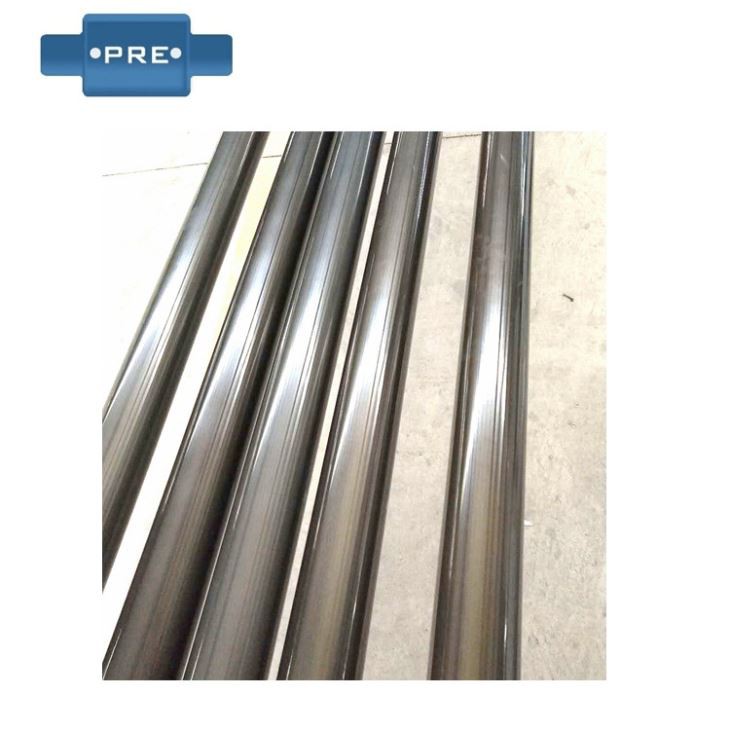

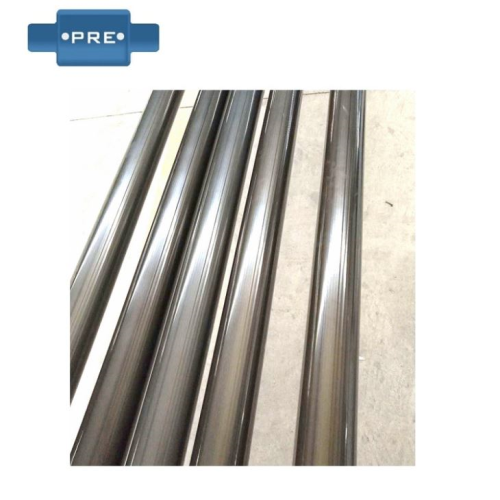

Aluminum alloy guide rolls, also called aluminum guide rolls, are mainly made of high-quality aluminum alloy materials. The guide rolls have high strength, low resistance, light weight, flexible rotation, no rust, wear and corrosion resistance, especially suitable for printing, packaging,...

Aluminum alloy guide rolls, also called aluminum guide rolls, are mainly made of high-quality aluminum alloy materials. The guide rolls have high strength, low resistance, light weight, flexible rotation, no rust, wear and corrosion resistance, especially suitable for printing, packaging, Precision machinery industry such as plastics and electronic batteries and various coil processing industries. The mold is made into various types of tubes, and has a rib structure and high strength.

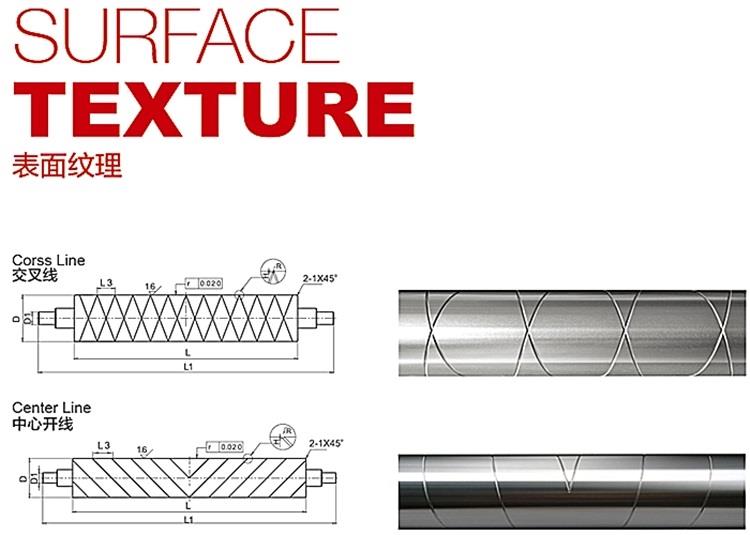

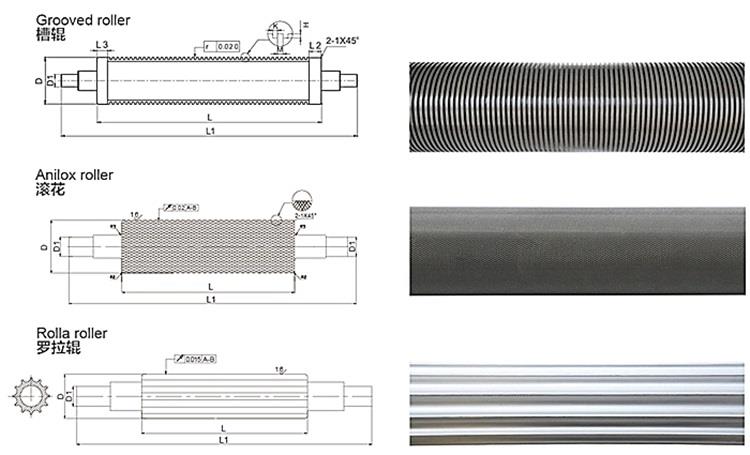

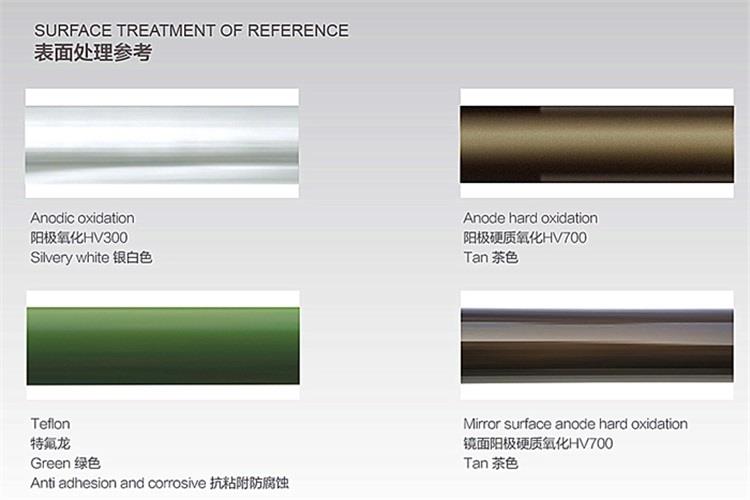

The aluminum guide roller is made of high-quality aluminum and is made by advanced processing technology. The surface is anodized hv300 (white) or hv700 (brown), the roll body finish is 0.8; the school balance is g2.5; the aluminum tube is generally 8- 10 ribs; can be customized according to customer requirements, groove roller, cross-line aluminum guide roller, center open aluminum guide roller, flower roller, anilox roller, cooling roller.

In the field of color printing and packaging machinery, PRE has been rapidly developing and applying itself through the continuous research and application of good technology. The factory specializes in the production of color printing machinery, packaging machinery, all kinds of flexible packaging machinery: aluminum guide roller, air expansion shaft, slip shaft, slip sleeve, magnetic powder controller and other series of mechanical supporting products, welcome new and old customers to inquire custom order!

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

Based on anodizing. The alumina guide roller is evenly covered with a water-soluble acrylic paint film to make the appearance bright and bright, and the surface of the material forms an anodized film and an acrylic paint film composite film. Feel smooth and delicate. In addition to the ability to produce the original oxidized color of the base energy to make more vivid colors such as red and green. Black powder coating has a total of more than 200 colors to choose from. Give the designer a broad space, the sandblasted aluminum guide roller performance film adhesion is strong and stable. It is not easy to peel off, acid, salt spray, mortar resistance, weather resistance, and aging resistance.

Good environmental performance. The external dirt has been completely washed after washing. Black fluorocarbon spray is non-volatile, non-oxidizing and non-polluting in the aluminum gas through electrostatic action. Fluorocarbon coatings. Therefore, it can have a durable color retention, and the anti-aging alloy base is sprayed with a polyvinylidene fluoride paint on the external surface. The fluorocarbon coating is a polyvinylidene fluoride. Its fluorocarbon bond is one of the strongest molecular bonds, and its molecular structure tubular aluminum guide roller is superior to its polymerization. And the advantages of superior ability to resist fading and staining. Fluorocarbon coating is used as a high-grade exterior coating process. Has a uniform color. Aluminum guide roller aluminum surface treatment process For aluminum, the guide roller guide roller is also known as the leading roller.

Application

Order Details

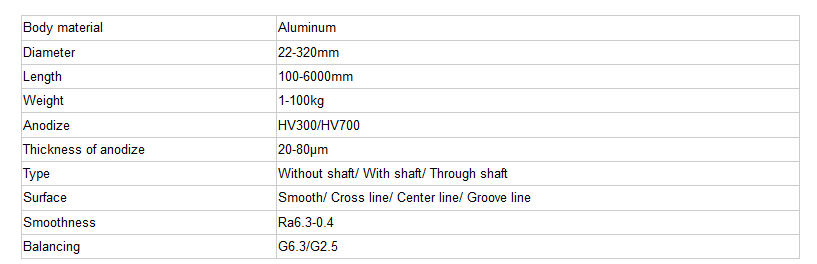

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: side roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy