Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tension controller is a kind of control instrument used in industrial control system to control the tension of strip and wire products to meet production requirements. The tension controller has two modes, manual and automatic, to control the tension during material winding and keep the tension constant.

Characteristics

The tension controller controls the ordinary three-phase asynchronous motor to output various required mechanical characteristics. It can output ideal winding characteristics.

Tension control is high precision and easy to adjust.

High efficiency and energy saving, the motor does not generate heat when the static torque is output, and the energy consumption is 50 [[%]] or more.

The structure is simple and reliable, only the motor, the controller two parts, long life, maintenance-free.

Batch use can reduce the ambient temperature by 4~8 °C, improve the grid power factor and reduce the transformer capacity increase investment.

It is used for drawing steel wire industry, which can effectively reduce the wire phenomenon of steel wire during wire discharge and reduce the waste wire generated during quenching.

Dot matrix LCD, Chinese and English display

Way of working

The tension controller is mainly used in the tension system of the magnetic powder clutch or magnetic powder brake. It is suitable for manual control, semi-automatic control (winding tension control) and fully automatic tension control system.

The manual tension controller manually adjusts the excitation current of the clutch or brake according to the change of the receiving or discharging diameter, so as to obtain a certain tension.

The semi-automatic tension controller is also called the winding-diameter tension controller. The controller can automatically detect the winding diameter of the receiving or discharging, and automatically adjust the excitation current of the clutch or brake according to the set target tension and the measuring coil diameter. The tension of the coil.

The automatic tension controller can measure the actual tension of the coil, and automatically adjust the excitation current of the clutch or brake according to the set target tension and the measured tension after PID calculation to control the tension of the coil. The fully automatic tension controller has extremely high tension control accuracy and is suitable for use in applications where the tension control accuracy is high.

The main parameters

1. Tension control range: 0 to full scale

2. Tension sensor: sensitivity 2mv/v DC10V

3. Control accuracy: 2[%]

4. Output current: 0.04~3A (RL=12 ohms)

5. Synchronous output: 0-20mA (or custom 4-20mA)

6. Power supply voltage: 220v±10[%]

Installation

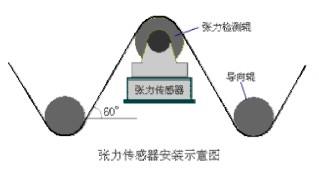

Select a guide roller or shaft at the location where the material tension is to be detected, and fix the bearing housing at both ends of the guide roller to the upper support plate of the tension sensor, and then fix the base of the tension sensor (lower support plate) to the machine. As shown below:

Tension controller installation

Tension controller installation

The angle between the guide roller or the shaft to which the tension sensor is mounted and the material is preferably about 60 degrees. If the angle is too small, the signal detected by the tension sensor is small, the sensitivity is lowered, and the tension control effect is affected.

When the tension detecting roller is installed by other means, the direction of the force of the material to the detecting roller should be consistent with the direction of the gravity of the detecting roller itself, so as to perform the "zero point" calibration.

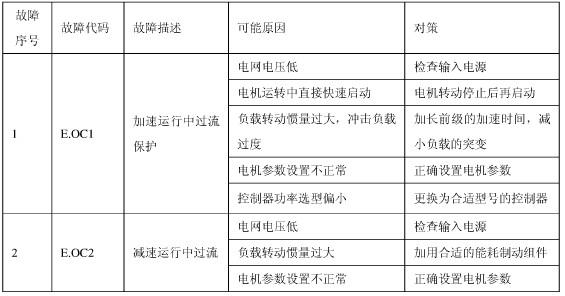

Common faults and troubleshooting

Previous: Regarding Tension Control, You Don't Know These Things.

Next: The Tension Controller Is Basically Divided Into Three Categories